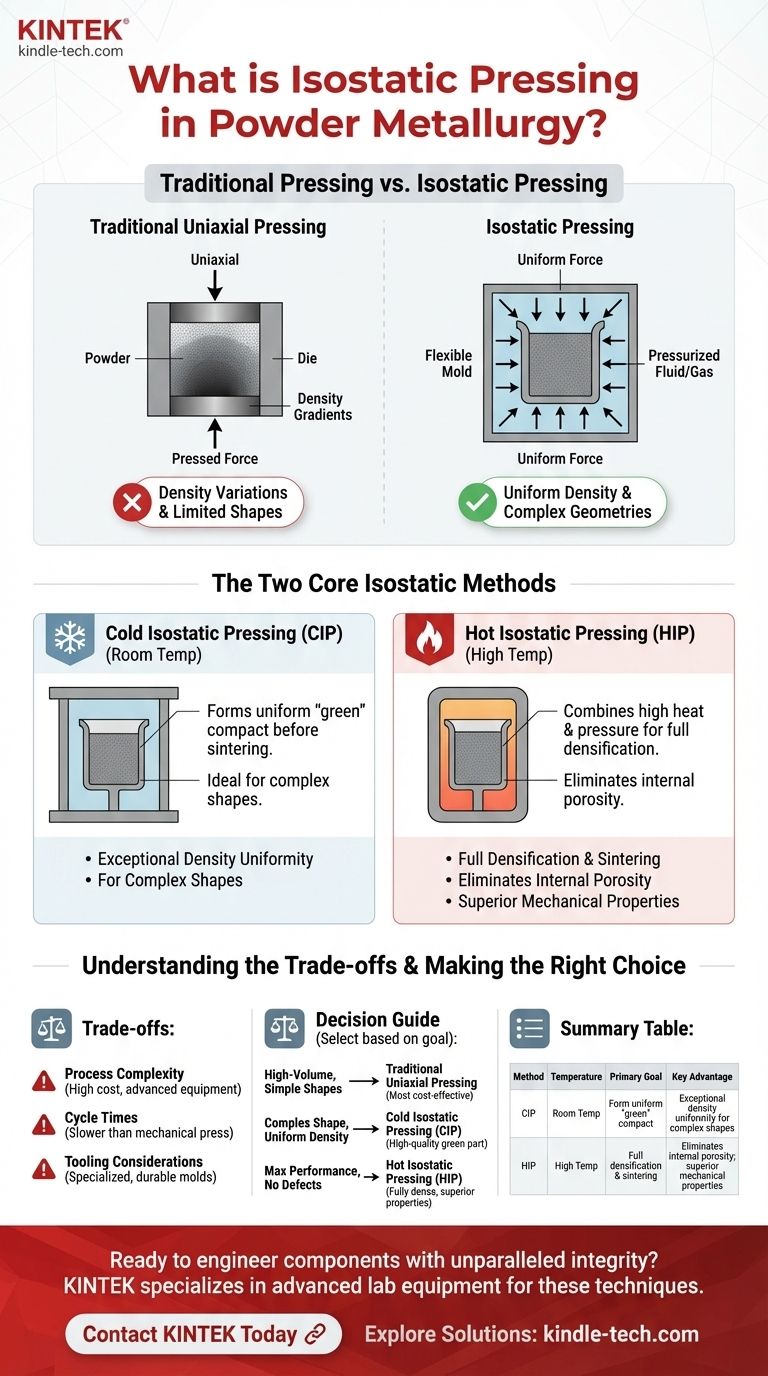

In powder metallurgy, isostatic pressing is a forming process that applies equal pressure to a metal powder compact from all directions simultaneously. Unlike traditional methods that press from a single direction, this uniform pressure creates components with exceptional consistency in density and microstructure, free from the geometrical limitations of other techniques.

The fundamental advantage of isostatic pressing is its ability to produce complex, robust metal parts with uniform density throughout. This makes it the superior choice for high-performance applications where internal integrity is critical.

The Problem With Traditional Pressing

The Limits of Uniaxial Force

Most conventional powder compaction uses a uniaxial press, which applies force from one or two directions. This process operates in stages where powder particles first slide to fill voids and then deform under immense pressure.

While effective for simple shapes, this one-directional force can create density variations within the part. Areas farther from the press ram may be less compact than areas closer to it, leading to inconsistent material properties.

The Isostatic Solution: Uniform Pressure

Isostatic pressing solves this by immersing the powder, which is typically held in a flexible mold, in a fluid or gas that is then pressurized. This applies the force equally on all surfaces of the part.

The result is a highly uniform "green" compact (an unsintered part) with consistent density and microstructure, regardless of the component's complexity or geometry.

The Two Core Isostatic Methods

Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing is performed at room temperature and is primarily used to compact powder into a solid form with maximum uniformity before final processing.

This method is ideal for creating the initial shape of a complex component, ensuring it has a consistent density before it undergoes the sintering (heating) stage.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) combines high heat and high pressure in a single step. This process takes place at elevated temperatures, often just below the material's melting point.

By applying pressure and thermal energy simultaneously, HIP serves to both compact the powder and sinter the particles together. This powerful combination is exceptionally effective at eliminating internal porosity, significantly increasing density, and improving the final mechanical properties of the part.

Understanding the Trade-offs

Process Complexity

Isostatic pressing, particularly HIP, requires more complex and expensive equipment than standard uniaxial pressing. The need for high-pressure vessels and, in the case of HIP, advanced heating systems, increases the operational cost.

Cycle Times

The process of pressurizing a vessel, heating it to extreme temperatures, and then cooling it down is inherently slower than the rapid cycle of a mechanical press. This makes isostatic pressing less suitable for high-volume production of simple parts.

Tooling Considerations

CIP often relies on flexible molds to transmit the pressure, which have different design and durability constraints compared to the rigid steel dies used in uniaxial pressing. HIP requires specialized molds made from materials like superalloys or graphite that can withstand extreme conditions.

Making the Right Choice for Your Goal

Selecting the correct pressing method depends entirely on the requirements of the final component.

- If your primary focus is high-volume production of simple shapes: Traditional uniaxial pressing remains the most cost-effective method.

- If your primary focus is creating a complex component with uniform density: Use Cold Isostatic Pressing (CIP) to form a high-quality green part before sintering.

- If your primary focus is achieving maximum performance and eliminating all internal defects: Use Hot Isostatic Pressing (HIP) to create a fully dense part with superior mechanical properties.

Ultimately, understanding how to apply isostatic pressure empowers you to engineer components with a level of integrity and complexity that other methods cannot achieve.

Summary Table:

| Method | Temperature | Primary Goal | Key Advantage |

|---|---|---|---|

| Cold Isostatic Pressing (CIP) | Room Temperature | Form uniform 'green' compact | Exceptional density uniformity for complex shapes |

| Hot Isostatic Pressing (HIP) | High Temperature | Full densification & sintering | Eliminates internal porosity; superior mechanical properties |

Ready to engineer components with unparalleled integrity?

Isostatic pressing is key to producing complex, high-performance parts free from density variations. KINTEK specializes in providing the advanced lab equipment and consumables needed to implement these precise powder metallurgy techniques.

Our experts can help you select the right pressing solution to achieve maximum density and superior mechanical properties for your specific application.

Contact KINTEL today to discuss how our solutions can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the cold isostatic pressing method? Achieve Uniform Density in Complex Parts

- What is the function of a Cold Isostatic Press (CIP) in the fabrication of pouch-type all-solid-state batteries?

- What are the considerations of powder metallurgy? Key Factors for Manufacturing Success

- What is the process of CIP and HIP? Forming vs. Densifying for Superior Materials

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts