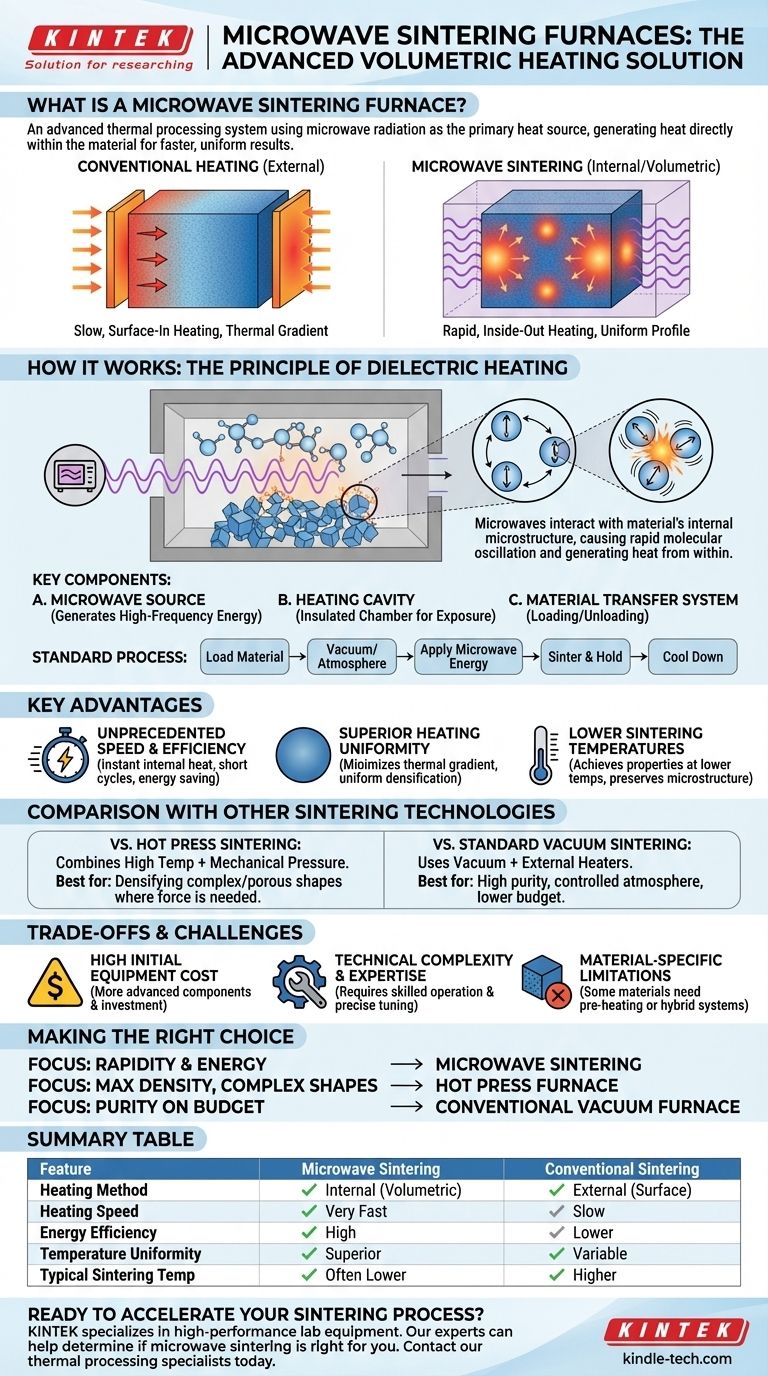

In essence, a microwave sintering furnace is an advanced thermal processing system that uses microwave radiation as its primary heating source. Unlike conventional furnaces that heat materials from the outside in, this technology generates heat directly within the material itself, leading to significantly faster and more uniform results.

The fundamental advantage of microwave sintering is its ability to achieve rapid, energy-efficient heating by directly coupling with a material's internal microstructure. This "volumetric" heating process often results in superior material properties and dramatically reduced processing times compared to traditional methods.

How Microwave Sintering Fundamentally Works

Conventional furnaces rely on conduction, convection, and radiation to transfer heat from external elements to the surface of a material. Microwave sintering operates on a completely different principle.

The Principle of Dielectric Heating

A microwave sintering furnace uses an electromagnetic field to generate heat. When ceramic materials are placed in this field, their internal microstructure (specifically, their dielectric properties) interacts with the microwaves.

This interaction causes rapid molecular oscillation, which generates heat from the inside out. This process is known as dielectric heating, the same principle used in a household microwave oven but applied with far greater precision and power.

Key System Components

A typical furnace is comprised of three main parts:

- A Microwave Source: Generates the high-frequency microwave energy.

- A Heating Cavity: A well-insulated chamber where the material is placed and exposed to the microwave field.

- A Material Transfer System: Manages the loading and unloading of the material being processed.

The Standard Operating Process

The process is precise and controlled. It involves loading the material, creating a vacuum or controlled atmosphere, applying microwave energy to heat the material to its sintering temperature, holding it there, and then cooling it down.

Key Advantages Over Conventional Methods

The shift from external to internal heating provides several distinct operational advantages that are critical for advanced material preparation.

Unprecedented Speed and Efficiency

Because heat is generated instantly within the material, the heating rate is exceptionally fast. This dramatically shortens the entire sintering cycle, saving both time and a significant amount of energy.

Superior Heating Uniformity

Traditional heating often creates a large temperature difference between the surface and the core of a material. Microwave heating minimizes this internal temperature gradient, promoting more uniform densification and reducing internal stresses.

Lower Sintering Temperatures

The efficiency of direct energy transfer means that desired material properties can often be achieved at lower overall sintering temperatures. This can help preserve finer microstructures and prevent unwanted grain growth.

Comparison with Other Sintering Technologies

To understand its value, it's useful to compare microwave sintering to other common high-temperature furnace technologies.

vs. Hot Press Sintering

A hot press sintering furnace combines high temperature with high mechanical pressure in a vacuum. While microwave sintering excels at uniform volumetric heating, hot pressing is superior for promoting densification in complex or porous structures where applied force is necessary.

vs. Standard Vacuum Sintering

A standard vacuum sintering furnace also uses a vacuum to prevent oxidation but relies on conventional external heating elements. Both methods produce high-purity results, but microwave sintering achieves them much faster and with greater energy efficiency.

Understanding the Trade-offs and Challenges

Despite its advantages, microwave sintering is not a universal solution. Its adoption requires careful consideration of its specific demands.

High Initial Equipment Cost

The technology and components involved in a microwave sintering furnace are more advanced than those in conventional systems, leading to a higher initial capital investment.

Technical Complexity and Expertise

Operating a microwave furnace effectively requires a higher level of technical skill. Parameters like microwave power and frequency must be carefully tuned for different materials, making the process more complex than traditional methods.

Material-Specific Limitations

Some materials do not absorb microwave energy well at lower temperatures. For these cases, hybrid furnaces that combine conventional electrical heaters with microwave sources are used to pre-heat the material until it becomes receptive to microwaves.

Making the Right Choice for Your Goal

Selecting the correct sintering technology depends entirely on your project's specific priorities regarding speed, material properties, and budget.

- If your primary focus is rapid processing and energy efficiency: Microwave sintering is the superior choice for its speed and direct, uniform heating capabilities.

- If your primary focus is achieving maximum density in complex shapes: A hot press furnace may be more suitable, as its use of high pressure is critical for densifying certain geometries.

- If your primary focus is preventing contamination on a tighter budget: A conventional vacuum furnace offers a controlled atmosphere to ensure product purity without the cost and complexity of microwave technology.

Ultimately, choosing the right furnace is about aligning the technology's core strengths with your most critical material and production goals.

Summary Table:

| Feature | Microwave Sintering | Conventional Sintering |

|---|---|---|

| Heating Method | Internal (Volumetric) | External (Surface) |

| Heating Speed | Very Fast | Slow |

| Energy Efficiency | High | Lower |

| Temperature Uniformity | Superior | Variable |

| Typical Sintering Temperature | Often Lower | Higher |

Ready to accelerate your material processing with advanced sintering technology?

KINTEK specializes in high-performance lab equipment, including advanced sintering furnaces. Our experts can help you determine if a microwave sintering furnace is the right solution to achieve faster cycle times, superior material properties, and significant energy savings for your laboratory.

Contact our thermal processing specialists today to discuss your specific application and goals.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost