A plasma arc furnace is a specialized type of furnace that uses a jet of high-temperature, ionized gas—known as plasma—to melt and process metals and other materials. Instead of traditional combustion or simple electric resistance, it employs a device called a plasmatron to generate a stable, controllable electric arc that creates the plasma, achieving extremely high temperatures with exceptional precision.

The core value of a plasma arc furnace is its ability to create an ultra-clean, highly controlled melting environment. This results in superior material purity and allows for the production of advanced, low-impurity alloys that are difficult or impossible to create with conventional furnace technologies.

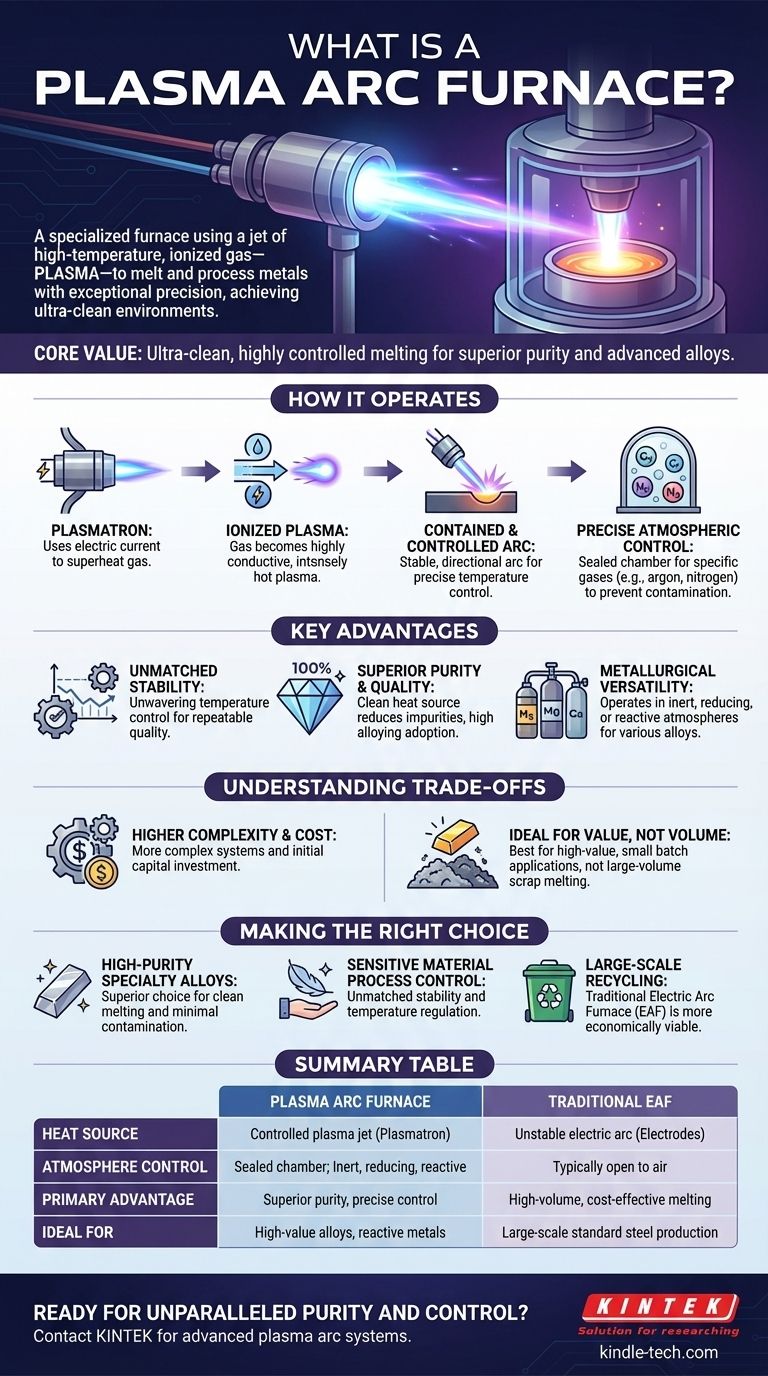

How a Plasma Arc Furnace Operates

The Role of the Plasmatron

A plasma arc furnace's heat source is the plasmatron. This device uses an electric current to superheat a flow of gas (like argon, nitrogen, or others).

This process strips electrons from the gas atoms, turning the gas into a highly conductive, intensely hot plasma.

A Contained and Controlled Arc

This plasma jet is directed at the material to be melted, transferring heat with incredible efficiency.

Unlike a traditional Electric Arc Furnace (EAF) with its chaotic arc, the plasma arc is highly stable and directional, allowing for precise temperature control.

Precise Atmospheric Control

The furnace chamber is sealed, allowing operators to introduce specific gases and control the atmosphere.

This prevents unwanted reactions with oxygen and nitrogen from the air and even allows for the creation of specialized materials, such as nitrided steels, by using nitrogen as the plasma gas.

Key Advantages Over Traditional Furnaces

Unmatched Process Stability

The ability to continuously adjust the plasmatron's electrical conditions provides unwavering temperature control. This stability is critical for sensitive alloys and repeatable quality.

Superior Purity and Material Quality

The clean heat source and controlled atmosphere significantly reduce the introduction of impurities into the melt. This results in a very high degree of purity in the final product.

It also ensures a high adoption rate of alloying additions, meaning expensive materials are not lost to oxidation or slag.

Unmatched Metallurgical Versatility

The furnace can operate in almost any desired atmosphere—inert, reducing, or even reactive.

This makes it possible to smelt low-carbon steels, specialty alloys, and reactive metals like titanium without contamination.

Understanding the Trade-offs

Higher Complexity and Cost

Plasma arc systems, with their plasmatrons and sophisticated gas and power controls, are more complex and have a higher initial capital cost than many conventional furnaces.

Ideal for Value, Not Volume

The emphasis on purity, control, and smaller batch sizes makes these furnaces ideal for high-value applications.

They are generally not the most economical choice for melting large volumes of standard-grade scrap metal, where traditional Electric Arc Furnaces excel.

Making the Right Choice for Your Goal

When considering a plasma arc furnace, your primary objective is the most important factor.

- If your primary focus is producing high-purity, specialty alloys: The plasma arc furnace is the superior choice for its clean melting and minimal contamination.

- If your primary focus is process control for sensitive materials: The stability and precise temperature regulation of the plasma arc are unmatched.

- If your primary focus is large-scale, low-cost metal recycling: A traditional Electric Arc Furnace is almost always the more economically viable solution.

Ultimately, the plasma arc furnace is a precision instrument for demanding metallurgical applications where material quality and purity cannot be compromised.

Summary Table:

| Feature | Plasma Arc Furnace | Traditional Electric Arc Furnace (EAF) |

|---|---|---|

| Heat Source | Controlled plasma jet from a plasmatron | Unstable electric arc between electrodes |

| Atmosphere Control | Sealed chamber; inert, reducing, or reactive gases | Typically open to air |

| Primary Advantage | Superior purity, precise control for sensitive alloys | High-volume, cost-effective melting of scrap |

| Ideal For | High-value specialty alloys, reactive metals (e.g., titanium) | Large-scale production of standard steels |

Ready to achieve unparalleled purity and control in your metal processing?

If your work involves developing high-value specialty alloys, reactive metals, or requires an ultra-clean melting environment, a plasma arc furnace is the precision instrument you need. KINTEK specializes in advanced lab equipment, including plasma arc systems, to help research and production laboratories push the boundaries of material science.

Contact our experts today to discuss how a plasma arc furnace can meet your specific metallurgical goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does heat treating make metal stronger? Optimize Your Metal's Strength and Durability

- What is the pressure in a pyrolysis reactor? A Guide to Optimizing Your Process

- What are 4 disadvantages of brazing? Understanding the Critical Limitations of This Joining Method

- What is metal sintering? A Guide to Cost-Effective, High-Volume Metal Part Production

- What is the process of a vacuum furnace? Achieve Superior Material Purity and Performance

- What's the difference between brazing and braze welding? Mastering Joint Strength & Application

- What is the role of a vacuum drying oven in the casting process of PEO-based polymer electrolyte membranes?

- What are the advantages of insulation in a furnace? Maximize Efficiency, Performance, and Lifespan