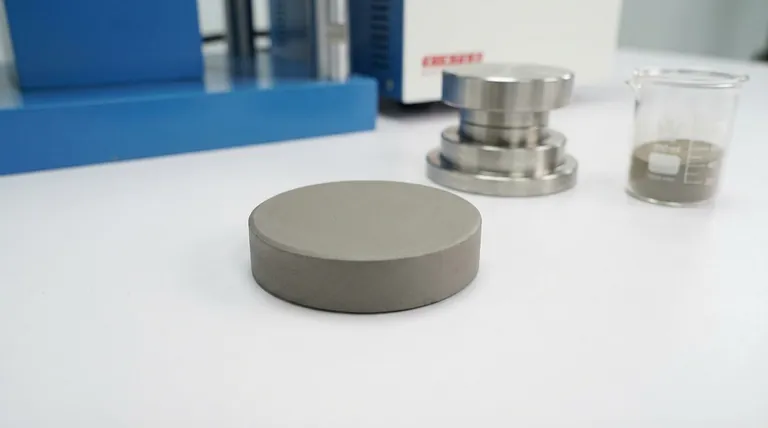

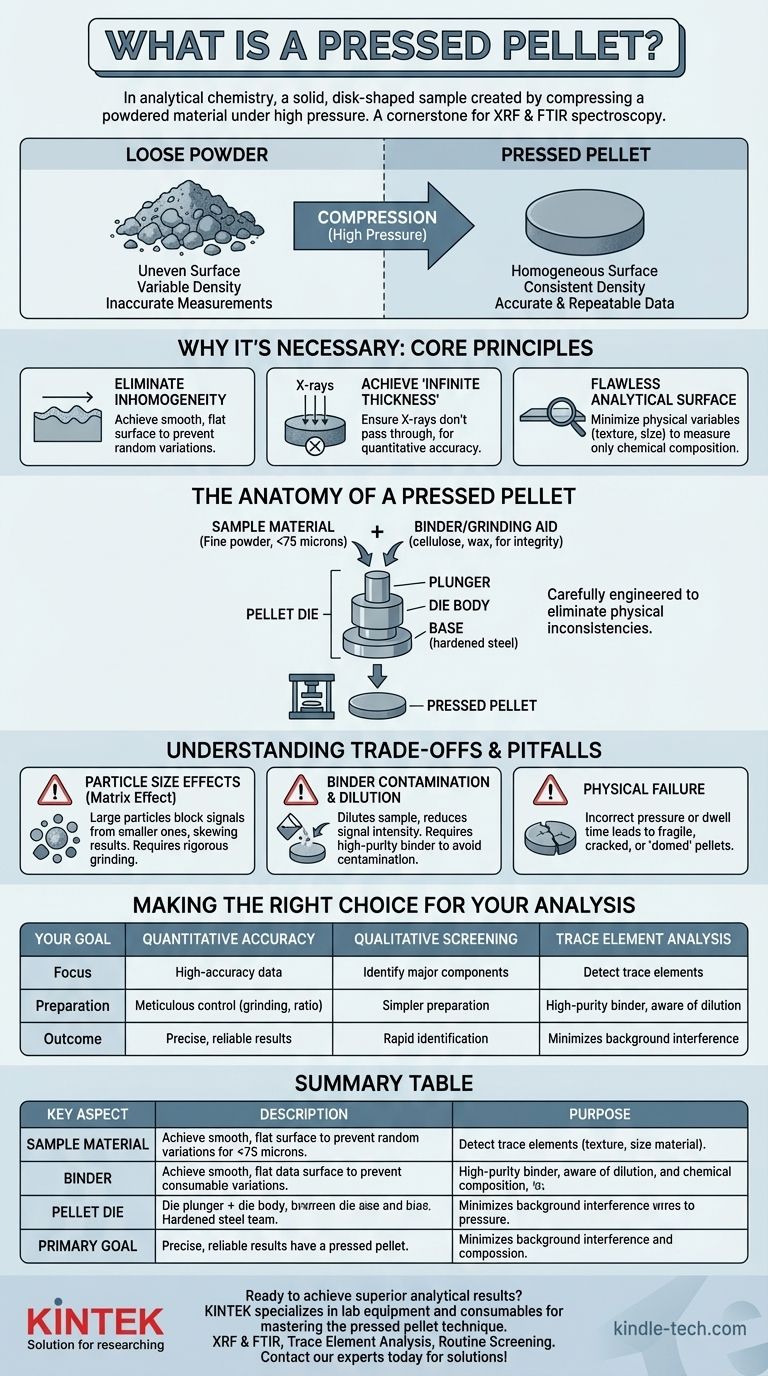

In analytical chemistry, a pressed pellet is a solid, disk-shaped sample created by compressing a powdered material under high pressure. This technique is a cornerstone of sample preparation for spectroscopic methods like X-ray Fluorescence (XRF) and Fourier Transform Infrared (FTIR) spectroscopy. It transforms a non-uniform loose powder into a sample with a smooth, flat, and homogeneous surface, which is essential for obtaining accurate and repeatable measurements.

A pressed pellet is not merely a compacted powder; it is a carefully engineered sample form designed to eliminate physical inconsistencies. The primary goal is to ensure that analytical measurements reflect the true chemical composition of the material, not random variations in its particle size or density.

The Core Principle: Why Pelletizing is Necessary

To understand the value of a pressed pellet, one must first appreciate the problems inherent in analyzing loose powders. The physical state of a sample can dramatically interfere with measurement accuracy.

The Problem of Surface Inhomogeneity

A loose powder is a collection of particles with varying sizes and shapes. This creates an uneven surface with voids and variable density.

When analyzed, this inconsistency causes measurement errors. For example, in XRF, X-rays can scatter unpredictably from the irregular surface, and lower-density areas will yield a weaker signal than higher-density areas, even if the chemical composition is identical.

Achieving "Infinite Thickness"

For accurate XRF analysis, a sample must be "infinitely thick." This means it is thick and dense enough that the primary X-ray beam does not penetrate through to the sample holder beneath it.

A pressed pellet provides the uniform density and thickness required to reliably meet this condition. A loose powder, by contrast, may have low-density pockets that allow X-rays to pass through, compromising the quantitative accuracy of the results.

The Goal: A Flawless Analytical Surface

Ultimately, the goal is to create a sample where the only variable is its chemical composition. By pressing a powder into a dense, solid pellet, you minimize physical variables like surface texture, particle size effects, and bulk density.

The Anatomy of a Pressed Pellet

A high-quality pressed pellet is typically made from two components, formed within a specialized piece of equipment.

The Sample Material

This is the substance you intend to analyze. It must be ground into a fine, uniform powder before pressing. A particle size of less than 75 microns is a common target, and for high-accuracy work, sub-50 microns is preferred.

The Binder or Grinding Aid

A binder is a substance mixed with the sample powder to help the particles adhere to one another, resulting in a durable, stable pellet. Common binders include microcrystalline cellulose, paraffin wax, or specialized commercial binding agents.

Binders also act as a lubricant or "grinding aid" during the pulverization step, preventing the sample from caking and ensuring a finer, more consistent particle size.

The Pellet Die

This is the tool set used to form the pellet. It consists of a hardened steel cylinder (the die body), a plunger, and a base. The powder is contained within the die and compressed by the plunger, typically using a hydraulic press.

Understanding the Trade-offs and Common Pitfalls

While essential, the pressed pellet technique is not without its challenges. Awareness of these issues is critical for producing reliable data.

Pitfall 1: Particle Size Effects

This is arguably the most significant source of error. If larger, heavier particles are present alongside smaller, lighter ones, the larger particles can disproportionately absorb or block the signals from the lighter elements.

This phenomenon, known as a matrix effect, can severely skew quantitative results. Rigorous and consistent grinding is the only way to mitigate this.

Pitfall 2: Binder Contamination and Dilution

While necessary for pellet integrity, the binder inherently dilutes the sample. This reduces the signal intensity for all elements, which can be particularly problematic when measuring trace elements near the instrument's detection limit.

Furthermore, the binder itself can contain trace contaminants that may interfere with the analysis. Using a high-purity binder and accurately accounting for its composition is crucial.

Pitfall 3: Physical Pellet Failure

Several things can go wrong during the pressing stage. If pressure is too low or dwell time is too short, the pellet will be fragile and may crumble.

Conversely, excessive pressure can trap air, leading to cracking or a "domed" surface as the pellet relaxes. A proper pressure and release cycle is key to creating a mechanically stable, flat pellet.

Making the Right Choice for Your Analysis

The rigor you apply to pellet preparation should match your analytical goals.

- If your primary focus is high-accuracy quantitative analysis: You must meticulously control every step, especially grinding to a fine, uniform particle size and maintaining a precise, consistent sample-to-binder ratio.

- If your primary focus is rapid qualitative screening: A simpler preparation with less emphasis on perfect grinding may be sufficient to identify the major components of a material.

- If your primary focus is trace element analysis: You must prioritize using a high-purity binder and be aware of its dilution effect; in some cases, an alternative method like fusion may be a better choice.

Mastering the pressed pellet technique is a fundamental skill that separates approximate results from truly reliable analytical data.

Summary Table:

| Key Aspect | Description | Purpose |

|---|---|---|

| Sample Material | Fine powder (<75 microns) of the substance to be analyzed. | Provides the chemical composition for measurement. |

| Binder | High-purity additive (e.g., cellulose, wax) mixed with the sample. | Ensures pellet integrity and stability; aids grinding. |

| Pellet Die | Hardened steel tool set (body, plunger, base) used with a hydraulic press. | Forms the powder into a solid, disk-shaped pellet under high pressure. |

| Primary Goal | To create a homogeneous, flat surface with "infinite thickness." | Eliminates physical inconsistencies for accurate, repeatable analysis. |

Ready to achieve superior analytical results?

The quality of your sample preparation directly impacts the accuracy of your data. KINTEK specializes in the lab equipment and consumables you need to master the pressed pellet technique, from high-performance hydraulic presses and durable pellet dies to high-purity binders.

We serve laboratories like yours, providing solutions for:

- XRF & FTIR Spectroscopy: Ensure your samples meet the requirements for precise quantitative and qualitative analysis.

- Trace Element Analysis: Minimize dilution and contamination with our high-purity materials.

- Routine Screening: Streamline your workflow with reliable, consistent preparation tools.

Let us help you eliminate preparation errors and get reliable data from every sample. Contact our experts today to discuss your specific application and find the perfect solution for your lab!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability