In the simplest terms, a pressed pellet is a solid, disc-shaped sample created by compressing a powder under high pressure. This technique is a standard laboratory method used to transform a loose, non-uniform powder into a dense, homogeneous solid, which is crucial for many types of scientific analysis and material testing.

The core purpose of creating a pressed pellet is to eliminate inconsistencies. By compacting a powder into a solid with a smooth, flat surface, you ensure that any subsequent measurement is representative of the entire sample, not just the random orientation of loose particles.

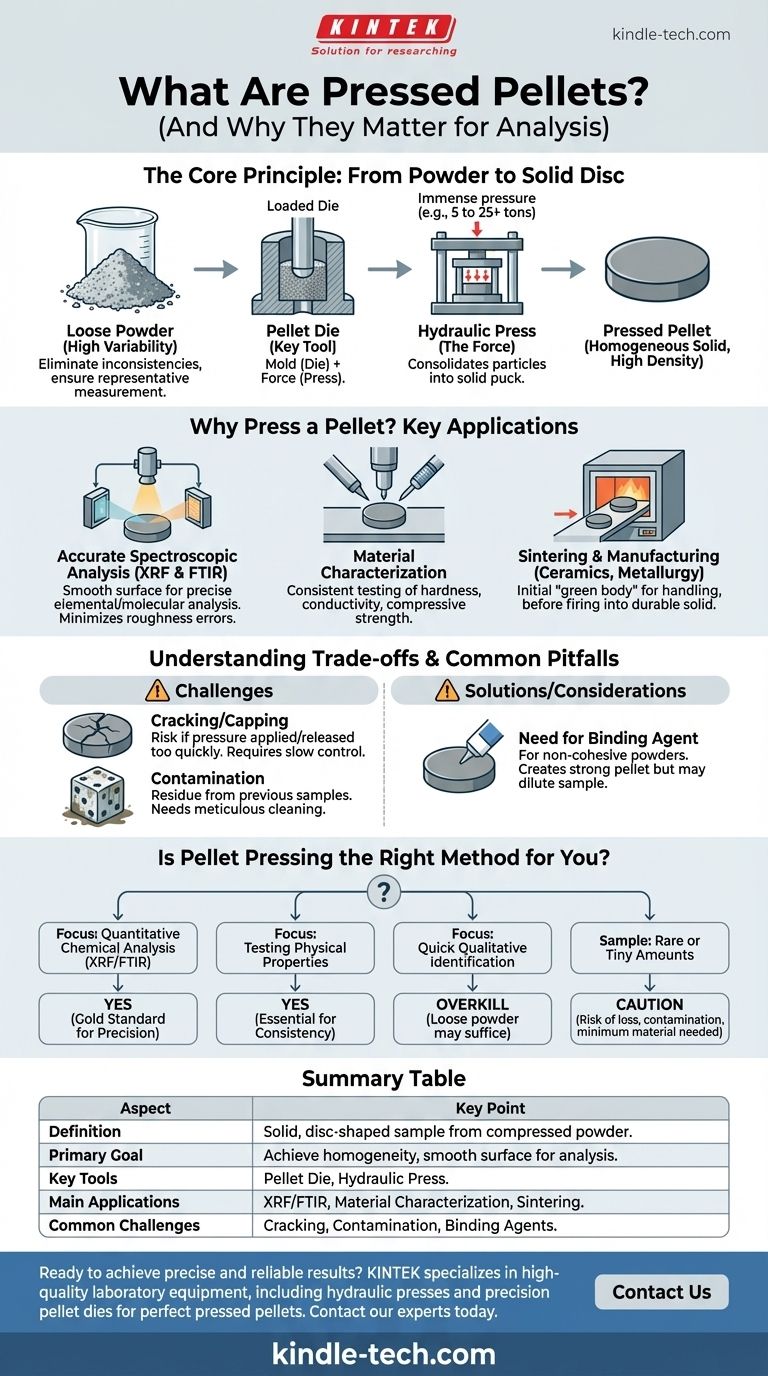

The Core Principle: From Powder to Solid Disc

The process of creating a pressed pellet is mechanically straightforward but requires precision. It fundamentally involves containing a powder and applying immense force to it.

The Goal: Homogeneity and Density

Loose powders have a high degree of variability. Particle sizes differ, and air gaps create an inconsistent surface and density. Pressing the powder forces the particles together, removes air, and creates a solid, uniform disc with a high density and a smooth surface.

The Key Tool: The Pellet Die

A pellet die is the mold used to form the pellet. It typically consists of a hollow cylinder (the body), a base, and one or two polished steel plungers. The powder is loaded into the die body, and the plungers are used to apply and distribute the pressure from the press.

The Force: The Hydraulic Press

To achieve the necessary compaction, a laboratory hydraulic press is used. These presses can generate forces ranging from a few tons to over 25 tons, applying immense pressure to the powder held within the die. This force is what consolidates the powder particles into a solid puck.

Why Press a Pellet? Key Applications

Creating a pellet is not just a procedural step; it is often a requirement for obtaining accurate and repeatable data. The technique is essential across several scientific and industrial fields.

For Accurate Spectroscopic Analysis (XRF & FTIR)

This is the most common laboratory application. Techniques like X-Ray Fluorescence (XRF) for elemental analysis and Fourier Transform Infrared (FTIR) spectroscopy for molecular analysis work best with a solid, flat sample. A pressed pellet provides a perfectly smooth and representative surface, minimizing errors caused by surface roughness and inconsistent sample density.

For Material Characterization

In materials science, researchers need to test the physical properties of new powdered materials, such as metals, polymers, or ceramics. Pressing the powder into a standardized pellet allows for consistent testing of properties like hardness, conductivity, and compressive strength.

For Sintering and Manufacturing

In ceramics and powder metallurgy, a pressed pellet is often the first step in creating a final product. This initial compressed form, sometimes called a "green body," has enough stability to be handled and then fired in a furnace in a process called sintering, which fuses the particles into a durable, solid object.

Understanding the Trade-offs and Common Pitfalls

While effective, the pellet pressing technique requires care to avoid common problems that can compromise the sample and the results.

The Risk of Cracking or Capping

If pressure is applied or released too quickly, air trapped within the powder can cause the pellet to crack or "cap" (where the top surface shears off). This is why a slow, controlled application of force is critical. Some materials are simply too brittle and will always be difficult to press.

The Problem of Contamination

The sample can be contaminated by the die material itself or by residues left from previous samples. Meticulous cleaning of the die between uses is non-negotiable for high-purity analysis.

The Need for a Binding Agent

Some powders, particularly organic materials or those with very fine, non-cohesive particles, will not form a stable pellet on their own. In these cases, a binding agent (like a wax or cellulose) is mixed with the sample. While this creates a strong pellet, the binder can also dilute the sample and potentially interfere with certain types of analysis.

Is Pellet Pressing the Right Method for You?

Choosing whether to press a pellet depends entirely on your analytical goal and the nature of your sample.

- If your primary focus is quantitative chemical analysis (XRF/FTIR): Yes, pressing a pellet is the gold standard for achieving the precision and repeatability required for accurate results.

- If your primary focus is testing the physical properties of a powder: Yes, creating a standardized pellet is essential for comparing results consistently across different batches or materials.

- If your primary focus is quick, qualitative identification: It might be overkill. Analyzing the loose powder directly may be faster and sufficient if high accuracy is not your main concern.

- If your sample is extremely rare or available only in tiny amounts: Be cautious. The process requires a minimum amount of material (typically a few hundred milligrams) and carries a risk of sample loss or contamination.

Ultimately, mastering the pressed pellet technique is a key skill for anyone needing to turn an unruly powder into a reliable, analyzable solid.

Summary Table:

| Aspect | Key Point |

|---|---|

| Definition | A solid, disc-shaped sample created by compressing powder under high pressure. |

| Primary Goal | Achieve sample homogeneity and a smooth, flat surface for accurate analysis. |

| Key Tools | Pellet Die and Hydraulic Press. |

| Main Applications | XRF/FTIR Spectroscopy, Material Characterization, Sintering/Manufacturing. |

| Common Challenges | Cracking, Contamination, Need for Binding Agents. |

Ready to achieve precise and reliable results with your powdered samples?

At KINTEK, we specialize in high-quality laboratory equipment, including robust hydraulic presses and precision pellet dies designed to create perfect pressed pellets every time. Whether you're conducting elemental analysis with XRF, molecular studies with FTIR, or testing material properties, our solutions ensure the sample consistency you need for accurate data.

Let KINTEK be your partner in precision. Contact our experts today to discuss your specific application and find the perfect pressing solution for your lab's needs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the functions of a laboratory hydraulic press in cathode research? Optimize High-Nickel Electrode Preparation

- What is the application of a laboratory hydraulic press in MEA development? Optimize Electrolyzer Performance

- What is the maintenance on a hydraulic press? Ensure Safety and Prevent Costly Downtime

- How do you clean KBr pellets? The Definitive Guide to Flawless FTIR Analysis

- How does a laboratory hydraulic press facilitate the sample preparation for cellulose citrate? Optimize IR Accuracy

- What can destroy a hydraulic press? Avoid These Common & Costly Mistakes

- How do you prepare a FTIR sample with KBr? Master the Technique for Clear, Accurate Spectra

- Is compression molding a fast process? A Guide to Faster Time-to-Market for Low-Volume Production