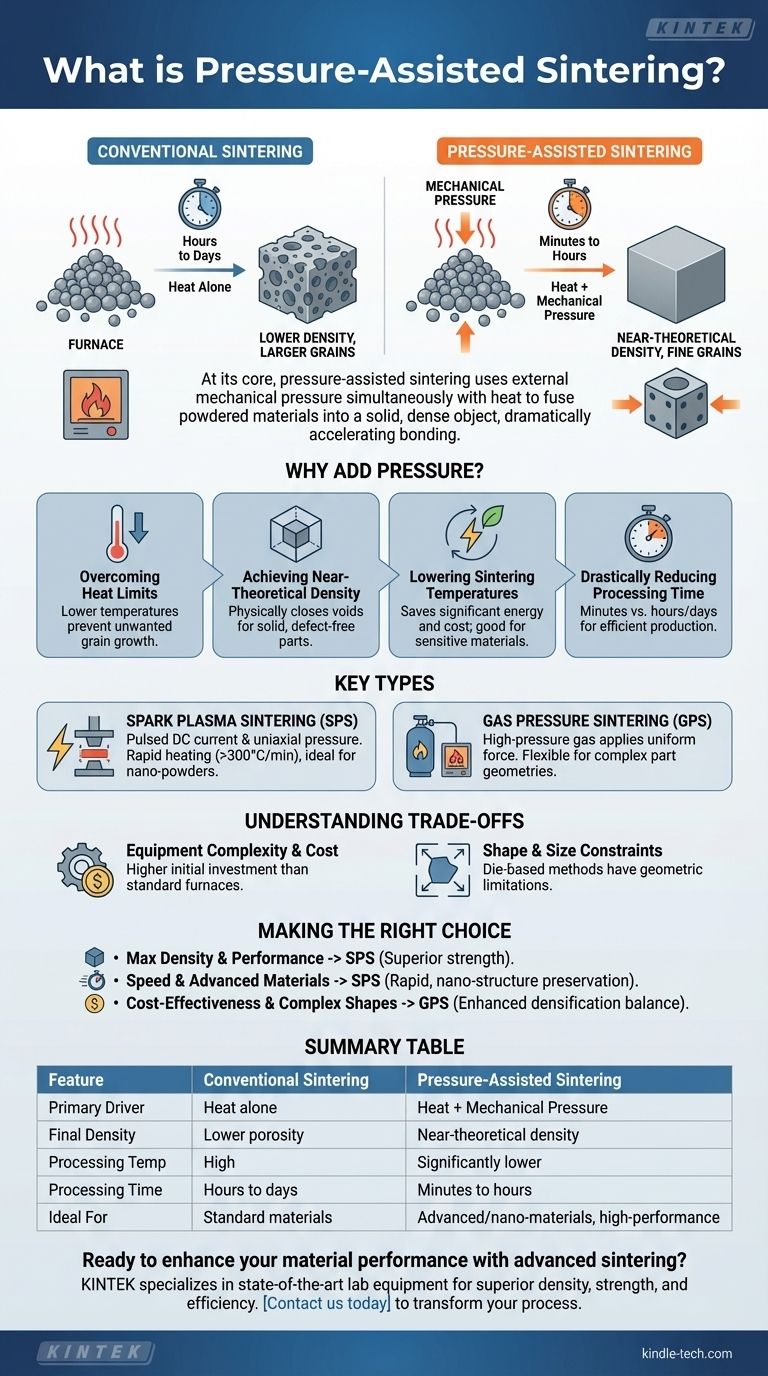

At its core, pressure-assisted sintering is a category of advanced manufacturing techniques that uses external mechanical pressure simultaneously with heat to fuse powdered materials into a solid, dense object. Unlike conventional sintering which relies on heat alone, this dual-action approach physically forces particles together, dramatically accelerating the bonding process and improving the final material's properties.

While traditional sintering slowly "bakes" powders together with heat, pressure-assisted sintering actively compacts them. This addition of force results in finished parts that are significantly denser and stronger, created at lower temperatures and in a fraction of the time.

Why Add Pressure to the Sintering Process?

Understanding the role of pressure is key to seeing why these techniques are so powerful. It fundamentally changes the dynamics of how individual particles bond to one another.

Overcoming the Limits of Heat Alone

Conventional sintering requires very high temperatures and long processing times to give atoms enough energy to diffuse across particle boundaries. This extended exposure to heat can cause unwanted grain growth, which can compromise the material's mechanical properties.

Achieving Near-Theoretical Density

The primary goal of sintering is to eliminate the empty space, or porosity, between the initial powder particles. Pressure physically forces particles closer together, mechanically closing these voids and making it easier to achieve a final part that is almost completely solid and free of defects.

Lowering Sintering Temperatures

Because mechanical pressure aids so much in densification, the process requires less thermal energy. Sintering temperatures can often be lowered by hundreds of degrees, saving significant energy and cost. This is also critical for processing temperature-sensitive or nano-sized materials that would be damaged by conventional high-heat methods.

Drastically Reducing Processing Time

The combination of heat and pressure is far more efficient than heat alone. Processes that would take hours or even days in a conventional furnace can often be completed in minutes using pressure-assisted techniques like Spark Plasma Sintering (SPS).

Key Types of Pressure-Assisted Sintering

Several distinct methods fall under this category, each with unique advantages.

Spark Plasma Sintering (SPS)

SPS is a highly advanced method that uses a powerful pulsed direct electrical current and uniaxial pressure. The current passes directly through the powder and the die, generating rapid, localized heat at the particle contact points.

This technique is prized for its extremely high heating rates (over 300°C/min) and short processing times. It is particularly effective for consolidating nano-sized powders without causing the grains to grow, preserving their unique properties.

Gas Pressure Sintering (GPS)

GPS is a more cost-effective alternative to other high-pressure methods like Hot Isostatic Pressing (HIP). It uses high-pressure gas within a furnace to apply uniform pressure to the part.

A key advantage of GPS is its flexibility with part geometry, as it does not have the shape limitations often associated with methods that use a rigid die, such as hot pressing.

Understanding the Trade-offs

While powerful, these methods are not a universal solution. It is critical to understand their limitations to make an informed decision.

Equipment Complexity and Cost

The machinery required for pressure-assisted sintering is significantly more complex and expensive than a standard high-temperature furnace. The initial capital investment can be substantial.

Shape and Size Constraints

Methods that rely on a physical die to apply pressure, such as hot pressing or many SPS configurations, are inherently limited to the shapes that can be pressed. Processes like GPS or HIP offer more geometric freedom but come with their own set of equipment challenges.

Making the Right Choice for Your Goal

Selecting the correct sintering method depends entirely on your project's specific priorities, from material properties to budget constraints.

- If your primary focus is maximum density and performance: Advanced methods like Spark Plasma Sintering are ideal for creating materials with fewer defects and superior strength.

- If your primary focus is speed and advanced materials: SPS is unparalleled for its rapid cycle times and its unique ability to consolidate nano-structured powders without degrading them.

- If your primary focus is cost-effectiveness for complex shapes: Gas Pressure Sintering provides a strong balance of enhanced densification without the high costs or geometric limits of other methods.

By understanding how the addition of pressure transforms the sintering process, you can select the precise manufacturing path to achieve your material performance targets.

Summary Table:

| Feature | Conventional Sintering | Pressure-Assisted Sintering |

|---|---|---|

| Primary Driver | Heat alone | Heat + Mechanical Pressure |

| Final Density | Lower porosity | Near-theoretical density |

| Processing Temperature | High | Significantly lower |

| Processing Time | Hours to days | Minutes to hours |

| Ideal For | Standard materials | Advanced/nano-materials, high-performance parts |

Ready to enhance your material performance with advanced sintering?

At KINTEK, we specialize in providing state-of-the-art lab equipment and consumables tailored to your research and production needs. Whether you're working with advanced ceramics, metals, or nano-powders, our expertise in pressure-assisted sintering solutions can help you achieve superior density, strength, and efficiency.

Contact us today to discuss how our sintering technologies can transform your manufacturing process and deliver the high-performance materials your projects demand.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification