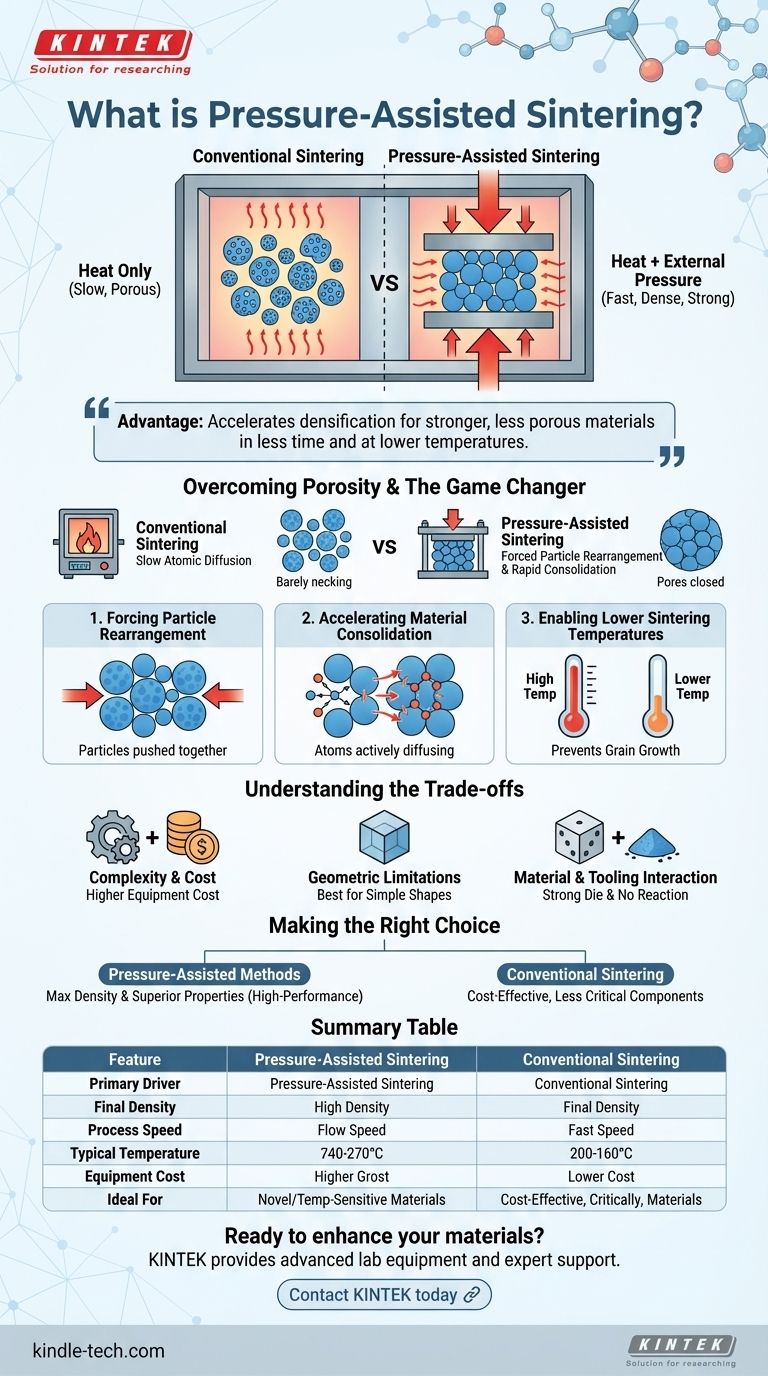

In essence, pressure-assisted sintering is an advanced manufacturing process that simultaneously combines high temperature and significant external mechanical pressure to compact powdered materials into a dense, solid object. Unlike conventional sintering which relies primarily on heat to bond particles, this method uses force to physically squeeze out the porous spaces between particles, dramatically enhancing the final product's properties.

The central advantage of applying external pressure during sintering is to accelerate the densification process. This allows for the creation of stronger, less porous materials, often at lower temperatures and in less time than is possible with heat-only methods.

The Fundamental Goal: Overcoming Porosity

What is Sintering?

At its core, sintering involves taking a collection of loose particles or a powder compact and heating it to a high temperature, always below the material's melting point.

The goal is to fuse these particles together, reducing the empty space (porosity) between them and forming a coherent, solid mass.

The Role of Atomic Diffusion

Heat provides the energy for atoms at the contact points of the particles to move, or diffuse. This atomic movement builds "necks" or bridges between particles, gradually closing the pores and shrinking the component.

The Limitation of Heat Alone

Relying solely on heat and atomic diffusion can be a slow process. For many high-performance materials, it may be insufficient to eliminate all porosity, leaving behind residual weaknesses in the final structure.

How External Pressure Changes the Game

Forcing Particle Rearrangement

Pressure-assisted sintering doesn't just wait for atoms to move; it actively forces the particles together. This mechanical pressure dramatically accelerates the initial stages of densification by rearranging particles and closing large pores.

Accelerating Material Consolidation

By applying external force, the process enhances the driving forces for diffusion and other mass transport mechanisms. This means the material consolidates into a dense solid much more rapidly than it would under heat alone.

Enabling Lower Sintering Temperatures

Because the applied pressure does so much of the work in compacting the material, the required temperature can often be significantly lowered. This is critical for preventing unwanted grain growth, which can compromise the mechanical properties of the final part.

Understanding the Trade-offs

Equipment Complexity and Cost

The machinery required to apply high, uniform pressure at extreme temperatures (e.g., a Hot Press or Hot Isostatic Press) is far more complex and expensive than a standard sintering furnace.

Geometric Limitations

Applying uniform pressure is most effective for simple shapes. Producing parts with complex geometries is more challenging and may require sophisticated and costly tooling (dies and molds).

Material and Tooling Interaction

The die material used to apply pressure must be strong enough to withstand the process conditions without deforming. It also cannot chemically react with the powdered material being compacted, which limits material combinations.

Making the Right Choice for Your Goal

Selecting the correct sintering method depends entirely on the desired outcome for the final component.

- If your primary focus is maximum density and superior mechanical properties: Pressure-assisted methods are the definitive choice for achieving near-theoretical density in high-performance ceramics, metals, and composites.

- If your primary focus is cost-effective production of less critical components: Conventional pressureless or vacuum sintering is often a more practical and economical approach for materials that densify easily.

- If your primary focus is processing novel or temperature-sensitive materials: The ability of pressure-assisted sintering to lower process temperatures is a critical advantage for preserving fine-grained or unique microstructures.

Ultimately, understanding how external pressure fundamentally alters the sintering dynamic allows you to select the most effective path to material excellence.

Summary Table:

| Feature | Pressure-Assisted Sintering | Conventional Sintering |

|---|---|---|

| Primary Driver | Heat + High External Pressure | Primarily Heat |

| Final Density | Very High (Near-Theoretical) | Moderate to High |

| Process Speed | Faster | Slower |

| Typical Temperature | Often Lower | Higher |

| Equipment Cost | Higher | Lower |

| Ideal For | High-Performance Ceramics/Metals | Cost-Effective, Simpler Parts |

Ready to enhance your materials with superior density and strength?

Pressure-assisted sintering is the key to unlocking peak performance for high-value components. At KINTEK, we specialize in providing the advanced lab equipment and expert support you need to master this powerful process.

We supply robust sintering solutions for laboratories focused on R&D and production of advanced ceramics, metals, and composites. Our team can help you select the right equipment to achieve your material goals efficiently.

Contact KINTEK today to discuss how our sintering expertise and reliable equipment can accelerate your path to material excellence.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the significance of the synchronous pressure in SiC-metal FGM? Bonding Excellence via Hot Pressing

- How big is the hot isostatic pressing market? Growth Drivers in Aerospace, Medical & 3D Printing

- What processing advantages does a vacuum hot press furnace provide? Achieve High-Density Fine-Grained Fluoride Ceramics

- What are the advantages of using a vacuum hot press for Al-4Cu alloys? Achieve 99% Density at Low Temps

- What is the role of a vacuum hot-pressing furnace in Fe-Cu-Ni-Sn-VN sintering? Boost Density & Wear Resistance

- What are the advantages of hot pressing? Uniaxial vs. HIP for Superior Part Density & Performance

- What functions do graphite molds serve in TiAl alloy vacuum hot-pressing? Optimize Your Sintering Process

- What role does a Vacuum Hot Press (VHP) furnace play in bonding aluminum and copper? Enhance Bond Quality