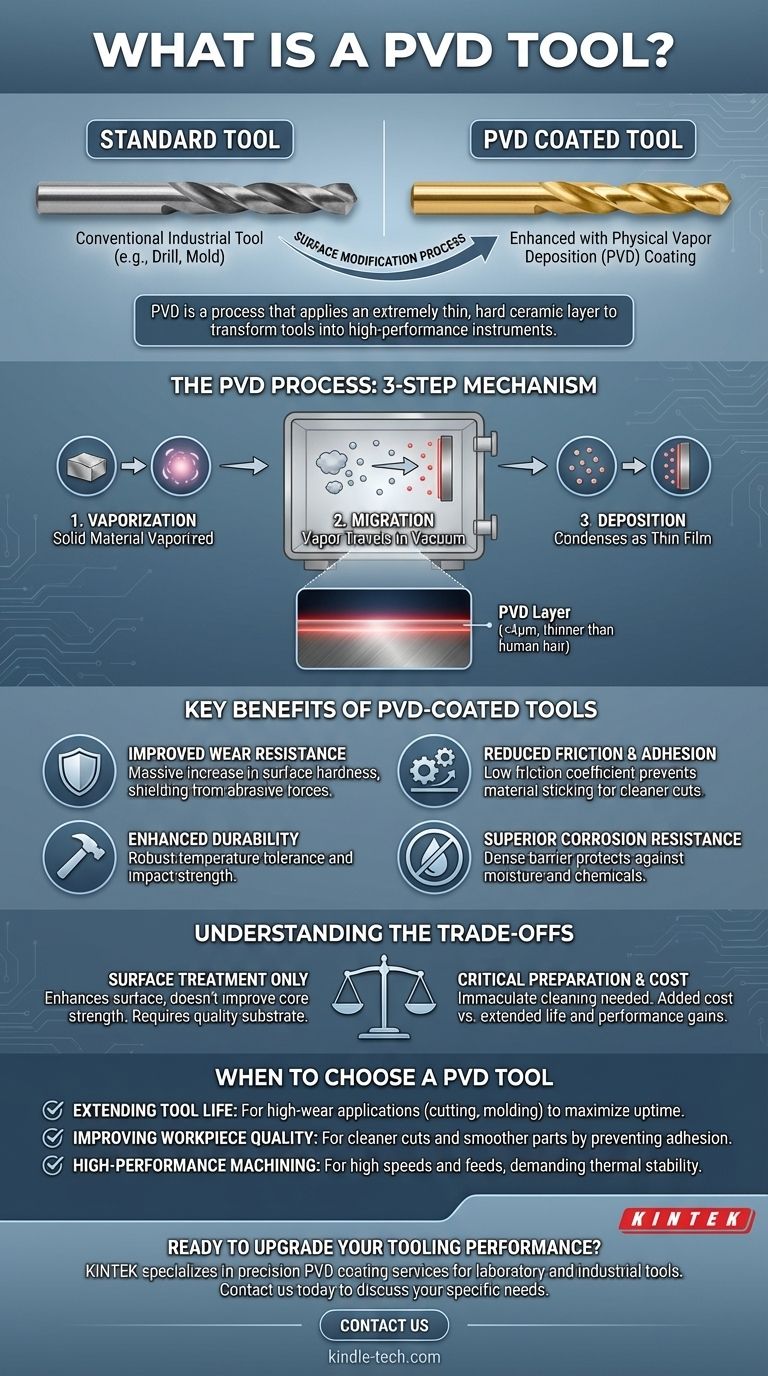

To be precise, a "PVD tool" is not a type of machine but rather a standard industrial tool, such as a drill bit or a plastic injection mold, that has been enhanced with a Physical Vapor Deposition (PVD) coating. This process applies an extremely thin, hard, and durable ceramic layer to the tool's surface to dramatically improve its performance and lifespan.

The key concept to understand is that PVD is a surface modification process, not a tool itself. It transforms a conventional tool into a high-performance instrument by bonding a microscopic layer of advanced material to its functional surfaces, enhancing properties like hardness and wear resistance.

What is Physical Vapor Deposition (PVD)?

Physical Vapor Deposition is a family of vacuum-based coating processes. In this method, a solid material is vaporized in a vacuum chamber and then deposited, atom by atom, onto the surface of a substrate, such as a steel cutting tool.

The Three-Step Mechanism

The entire process is clean, environmentally friendly, and happens at a microscopic level. It consists of three fundamental stages:

- Vaporization: A solid coating material (often a ceramic like Titanium Nitride) is vaporized into a plasma of atoms or molecules using heat or ion bombardment.

- Migration: These vaporized particles travel across the vacuum chamber toward the tool being coated.

- Deposition: The particles condense on the tool's surface, forming a very thin, highly uniform, and dense film.

The Result: A High-Performance Surface

The final PVD coating is typically a ceramic layer less than 4 micrometers thick—thinner than a human hair. Despite its thinness, this layer is exceptionally hard, pure, and strongly bonded to the underlying tool.

Key Benefits of PVD-Coated Tools

Applying a PVD coating is a strategic decision to solve specific operational challenges. The benefits directly address the most common failure points for industrial tools.

Drastically Improved Wear Resistance

The primary advantage is a massive increase in surface hardness. This protective ceramic layer shields the tool from the abrasive forces common in metalworking and molding, significantly extending its functional life.

Reduced Friction and Adhesion

PVD coatings have a very low coefficient of friction. This lubricity prevents material from the workpiece—such as metal chips or molten plastic—from sticking to the tool. This leads to cleaner cuts, smoother molded surfaces, and less downtime for tool cleaning.

Enhanced Durability and Resilience

The coatings are engineered for toughness. They provide robust temperature tolerance and impact strength, allowing the tool to perform reliably under demanding conditions without degrading.

Superior Corrosion Resistance

The dense, non-porous PVD layer acts as a barrier, protecting the base metal of the tool from moisture and chemicals. This makes PVD-coated tools more resistant to corrosion than those treated with traditional methods like electroplating.

Understanding the Trade-offs

While highly effective, the PVD process is not a universal solution. It's essential to understand its context to make informed decisions.

It Is a Surface Treatment

PVD enhances the surface properties of a tool. It will not improve the core strength of the base material. A high-quality coating cannot compensate for a low-quality tool.

Substrate Preparation is Critical

The success of the coating is entirely dependent on its adhesion to the tool. The tool's surface must be immaculately clean before entering the PVD chamber, as any contaminant will create a point of failure for the coating.

Added Cost vs. Extended Life

PVD coating adds an extra step and cost to the manufacturing process. This investment must be weighed against the expected gains in tool lifespan, reduced machine downtime, and improved quality of the final product. For high-volume or precision manufacturing, the return on investment is almost always positive.

When to Choose a PVD-Coated Tool

The decision to use a PVD-coated tool should be based on your specific operational goals.

- If your primary focus is extending tool life: PVD is an excellent choice for cutting tools, drills, and molds that experience high wear, as it directly maximizes their operational uptime.

- If your primary focus is improving workpiece quality: The low-friction surface of a PVD tool prevents material galling and adhesion, resulting in a cleaner cut or a smoother molded part.

- If your primary focus is high-performance machining: In applications that demand high speeds and feeds, the thermal stability and lubricity of PVD coatings are essential for preventing tool failure.

Ultimately, choosing a PVD-coated tool is about elevating a standard component into a precision instrument engineered for durability and peak performance.

Summary Table:

| Property | Benefit for Your Tool |

|---|---|

| Wear Resistance | Drastically extends tool life in abrasive applications. |

| Friction Reduction | Prevents material sticking, ensuring cleaner cuts and smoother surfaces. |

| Corrosion Resistance | Protects the base metal from moisture and chemicals. |

| Durability | Provides toughness and thermal stability for high-performance machining. |

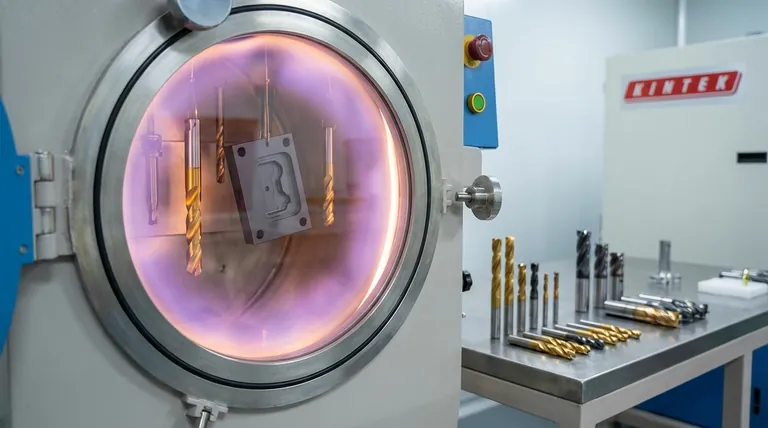

Ready to upgrade your tooling performance?

PVD coating can transform your standard tools into durable, high-performance assets that reduce downtime and improve product quality. KINTEK specializes in precision PVD coating services for laboratory and industrial tools, including cutting tools, molds, and custom components. Our advanced coating solutions are engineered to meet the demanding needs of modern manufacturing.

Contact us today to discuss how our PVD coatings can solve your specific wear and performance challenges. Let's enhance your tool's lifespan and efficiency together.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use