In simple terms, a quenching furnace is specialized industrial equipment designed not just to heat materials like metal alloys, but to then cool them with extreme speed and precision. This process, known as quenching, is a critical step in heat treatment used to lock in desirable material properties, most notably hardness and strength. It achieves this by rapidly changing the metal's internal crystalline structure before it has a chance to settle into a softer state.

A quenching furnace is fundamentally a tool for controlled thermal shock. Its primary value lies in its ability to manage the rapid cooling phase of a heat treatment cycle, which is what ultimately determines the final mechanical properties of the workpiece.

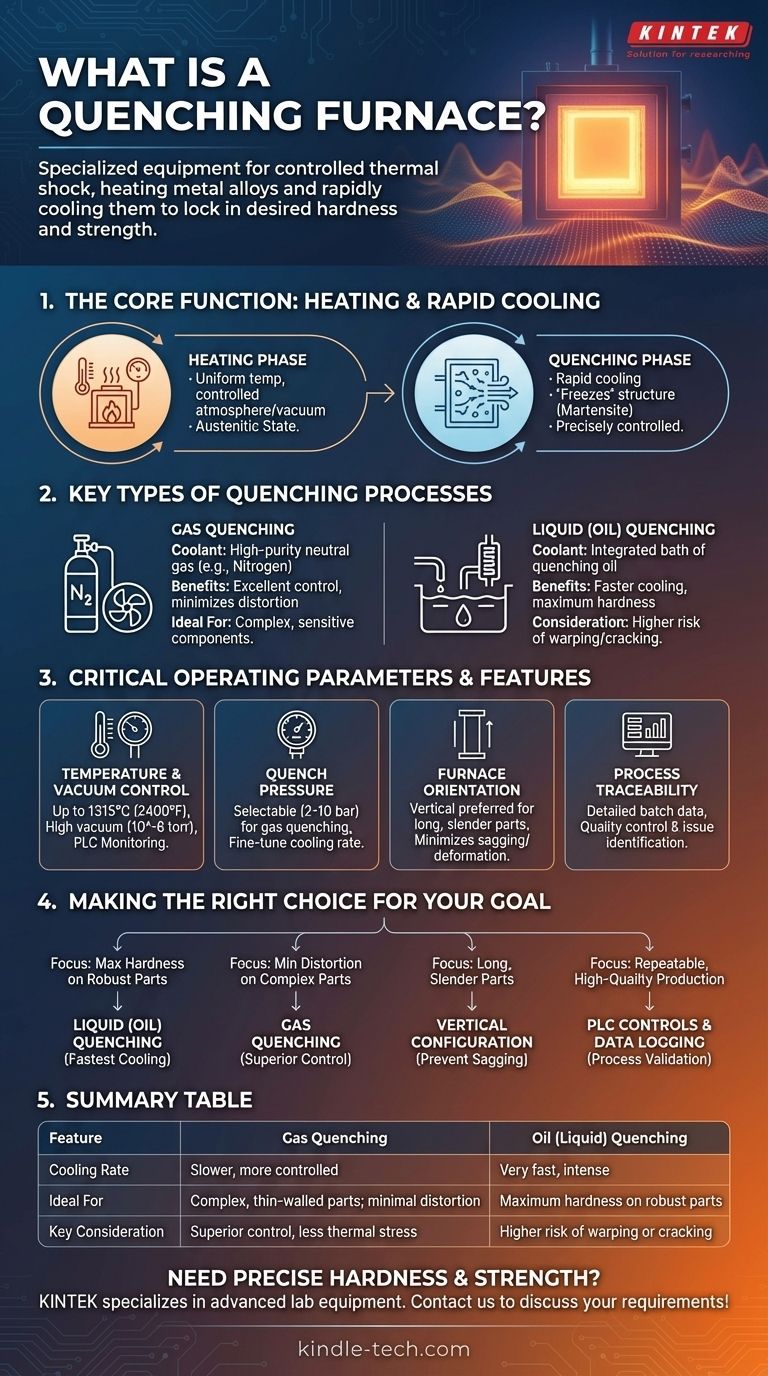

The Core Function: From Heating to Rapid Cooling

The entire purpose of a quenching furnace revolves around a two-stage process. The heating phase is important, but the quenching phase is what defines the equipment and the outcome.

The Heating Phase

Before quenching can occur, the workpiece must be heated to a specific, uniform temperature. This is often done in a vacuum or a controlled atmosphere to prevent oxidation and ensure the material is in the correct austenitic state, ready for transformation.

The Quenching Phase

This is the critical step. Once the target temperature is reached, the workpiece is subjected to rapid cooling. This "freezes" the material's internal structure in a hardened state, such as martensite. The speed and medium of this cooling process are precisely controlled by the furnace.

Key Types of Quenching Processes

While the goal is always rapid cooling, the method can vary significantly depending on the material and desired outcome. The two primary methods in modern vacuum furnaces are gas and liquid quenching.

Gas Quenching

In gas quenching, the hot workpiece is cooled by introducing a high-purity, neutral gas like nitrogen at high pressure. The furnace circulates this gas to remove heat quickly and uniformly.

This method offers excellent control over the cooling rate and minimizes the risk of part distortion, making it ideal for complex or sensitive components.

Liquid (Oil) Quenching

Liquid quenching involves moving the heated workpiece from the vacuum chamber into an integrated bath of quenching oil. This provides a much faster rate of cooling compared to gas.

While highly effective for achieving maximum hardness, the thermal shock is more severe, which can increase the risk of warping or cracking in some parts. These furnaces often include condensers to capture and recycle oil vapor.

Critical Operating Parameters and Features

Modern quenching furnaces are sophisticated systems defined by precision control and robust design.

Temperature and Vacuum Control

These furnaces operate at high temperatures, often up to 1315°C (2400°F), while maintaining a high vacuum in the 10^-6 torr range. A Programmable Logic Controller (PLC) typically manages the system, monitoring temperature in real-time to ensure process accuracy.

Quench Pressure

For gas quenching furnaces, the gas pressure is a key variable. It is often selectable, ranging from 2 bar to 10 bar, allowing operators to fine-tune the cooling rate based on the specific requirements of the workpiece.

Furnace Orientation

The physical layout of the furnace is a critical design choice. A vertical furnace is often preferred for long, slender parts like shafts or rods, as hanging the part vertically minimizes the risk of sagging and deformation during the intense heat cycle.

Process Traceability

Advanced systems allow operators to log detailed batch information, such as part numbers and process parameters. This data is crucial for quality control, allowing for precise monitoring and rapid identification of any issues.

Making the Right Choice for Your Goal

Selecting the appropriate quenching process is a critical decision based on the specific goals for the finished component.

- If your primary focus is achieving maximum hardness on robust parts: Liquid (oil) quenching provides the fastest cooling rate to ensure a complete martensitic transformation.

- If your primary focus is minimizing distortion on complex or thin-walled parts: Gas quenching offers superior control over the cooling rate, reducing thermal stress.

- If your primary focus is processing long, slender parts like shafts or plates: A vertical furnace configuration is essential to prevent gravity-induced deformation at high temperatures.

- If your primary focus is ensuring repeatable, high-quality production: A furnace with integrated PLC controls and data logging capabilities is non-negotiable for process validation and traceability.

Ultimately, the right quenching furnace is the one that provides precise and repeatable control over the cooling cycle for your specific application.

Summary Table:

| Feature | Gas Quenching | Oil (Liquid) Quenching |

|---|---|---|

| Cooling Rate | Slower, more controlled | Very fast, intense |

| Ideal For | Complex, thin-walled parts; minimal distortion | Maximum hardness on robust parts |

| Key Consideration | Superior control, less thermal stress | Higher risk of warping or cracking |

Need to achieve precise hardness and strength for your metal components? KINTEK specializes in advanced lab equipment, including quenching furnaces for reliable heat treatment. Our experts can help you select the right system—whether gas or oil quenching—to ensure repeatable, high-quality results for your laboratory's specific materials and applications. Contact us today to discuss your requirements!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What are sintered components? A Guide to High-Efficiency Metal Parts Manufacturing

- How does homogenization annealing in a vacuum high-temperature furnace benefit Fe-Cr-Al-Si alloys? Enhance Material Quality

- What are the critical factors which affect the heat treatment process? Master Time, Temperature, and Cooling for Superior Results

- What materials are used in high temperature brazing? Joining Superalloys, Ceramics & More

- How does a precision furnace affect 316LN phase transformation? Control Sigma Phase & Prevent Micro-Cracks

- Is an advantage of vacuum heat treatments reduced scaling and decarburization? Achieve Pristine, Clean Metal Parts

- How do you clean a vacuum furnace? A Step-by-Step Guide to Prevent Contamination and Ensure Process Integrity

- What experimental conditions does a high-vacuum dehydrogenation furnace provide? Test Zirconia Coating Integrity