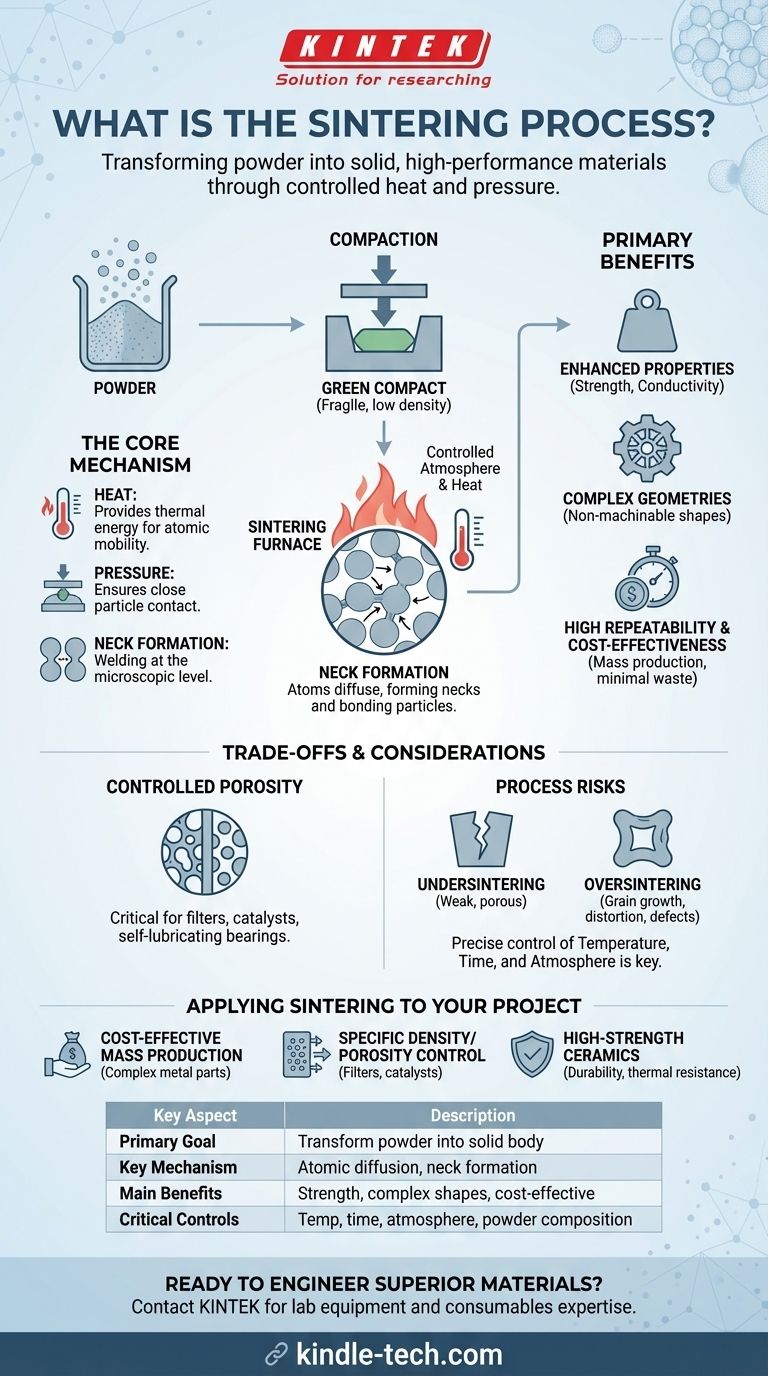

At its core, sintering is a manufacturing process that transforms a mass of powder into a solid, dense body. It achieves this by applying high heat and pressure at a temperature below the material's melting point, causing the individual particles to bond together. This foundational technique is central to powder metallurgy for creating metal parts and to the production of high-strength ceramics.

Sintering is not simply about making a solid object from powder; it is a highly controlled engineering method for manipulating a material's final properties—like strength, density, and conductivity—by fusing particles together at a microscopic level without ever melting them.

How Sintering Fundamentally Works

The Goal: From Loose Powder to Solid Part

The process begins with a specially composed powder. This powder is first compacted into a desired shape, often called a "green compact," which is fragile and has low density. The ultimate goal is to convert this loose form into a strong, unified component.

The Role of Heat and Pressure

The compacted part is heated in a controlled-atmosphere furnace. The heat provides the thermal energy needed for atoms to become mobile and diffuse across the boundaries of adjacent particles. Pressure ensures the particles remain in close contact, facilitating this atomic movement.

Neck Formation: The Key to Strength

The true magic of sintering happens at the microscopic level through a process called neck formation. As atoms migrate between the contact points of individual powder particles, they form small bridges, or "necks." These necks grow wider as the process continues, effectively welding the particles together.

Reducing Porosity

As these necks expand, the empty spaces, or pores, between the particles shrink and close up. This reduction in porosity is directly responsible for the increase in the material's relative density and overall strength. The final part becomes a solid, cohesive mass rather than a collection of individual grains.

The Primary Benefits of Sintering

Enhanced Material Properties

By creating a dense, unified microstructure, sintering dramatically improves a material’s physical properties. This commonly includes significant increases in strength, hardness, electrical conductivity, thermal conductivity, and in some cases, even optical transparency.

Manufacturing Complex Geometries

Sintering enables the mass production of parts with complex or non-machinable geometries. Because the initial shape is formed by compacting powder, intricate designs that would be difficult or wasteful to create with traditional subtractive manufacturing are made possible.

High Repeatability and Cost-Effectiveness

For large production volumes, sintering is a highly repeatable and cost-effective process. It produces near-net-shape parts that require minimal or no finishing operations, reducing material waste and processing time while ensuring high accuracy from part to part.

Understanding the Trade-offs and Considerations

Porosity is a Control Parameter

While sintering is often used to eliminate porosity, it can also be used to create parts with a specific, controlled level of porosity. This is critical for applications like self-lubricating bearings, filters, or catalysts, where interconnected pores are a functional requirement.

The Risk of Flawed Sintering

The process requires precise control over temperature, time, and atmosphere. Undersintering results in insufficient neck growth, leaving the part weak and porous. Oversintering can lead to excessive grain growth, part distortion, or even surface defects like blistering, which compromises the final properties.

Material and Process Complexity

Effective sintering relies on deep knowledge of material science. Factors like powder composition, particle size distribution, and the removal of lubricants (dewaxing) must be carefully managed to achieve the desired outcome. The process involves a complex interplay of variables that must be optimized for each specific application.

How to Apply This to Your Project

Based on these principles, you can determine if sintering aligns with your manufacturing goals.

- If your primary focus is cost-effective mass production of complex metal parts: Sintering is an excellent choice, as it bypasses many traditional machining steps and minimizes material waste.

- If your primary focus is creating materials with specific density or porosity: Sintering offers precise control over the final microstructure, making it ideal for filters, catalysts, or fully dense components.

- If your primary focus is producing high-strength ceramic components: Sintering is a foundational manufacturing process for achieving the required durability and thermal resistance in advanced ceramics.

Ultimately, sintering provides a powerful and versatile method for engineering a material's properties from the particle level up.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Transform loose powder into a solid, dense body. |

| Key Mechanism | Atomic diffusion and neck formation between particles. |

| Main Benefits | Enhanced strength, complex geometries, cost-effective mass production. |

| Critical Controls | Temperature, time, atmosphere, and powder composition. |

Ready to engineer superior materials with precise sintering?

At KINTEK, we specialize in the lab equipment and consumables that make advanced sintering processes possible. Whether you are developing new metal alloys, high-performance ceramics, or porous filters, our expertise and products support the precise control required for successful outcomes.

Contact our experts today to discuss how we can help you achieve your material property goals through reliable sintering solutions.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects