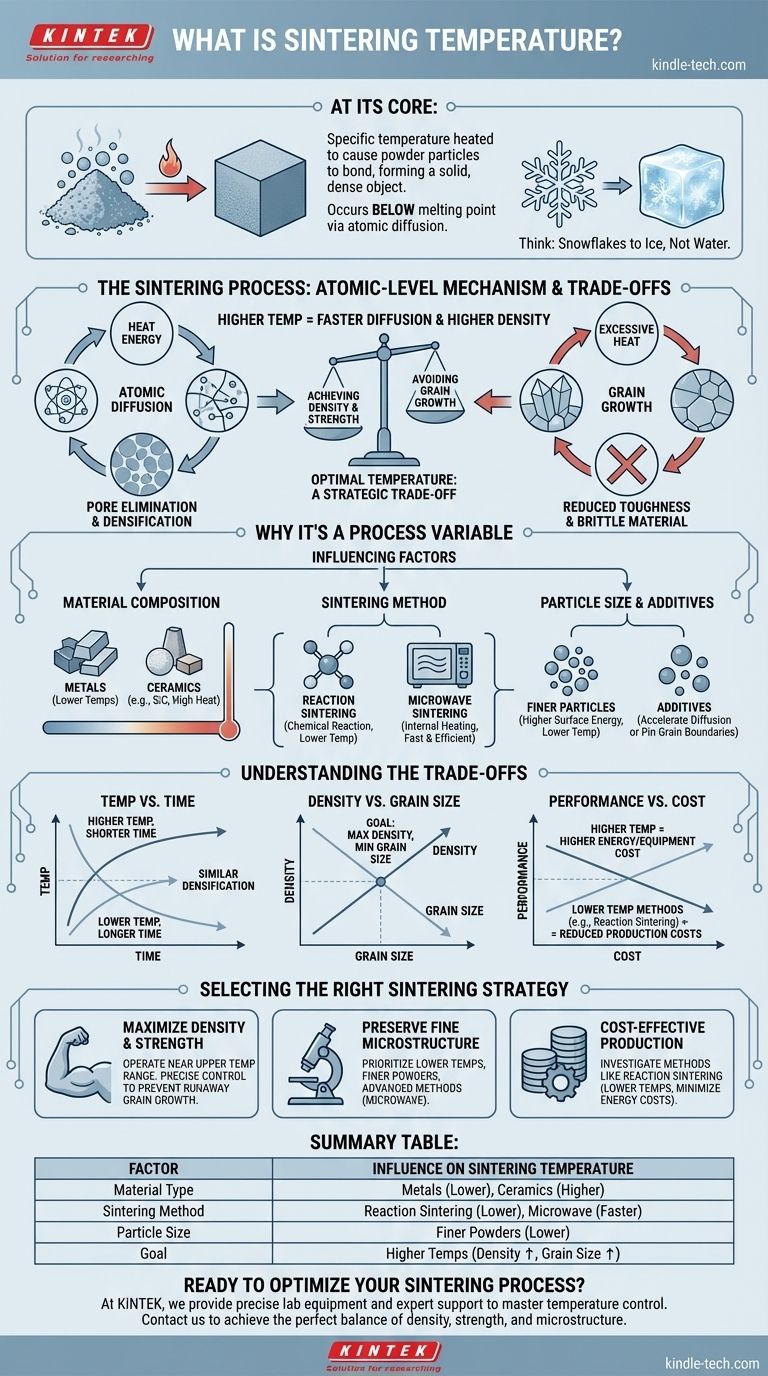

At its core, sintering temperature is the specific temperature at which a powdered material is heated to cause its individual particles to bond together, forming a solid, dense object. This process occurs below the material's melting point, relying on atomic diffusion rather than liquefaction to consolidate the powder into a coherent mass. The precise temperature is one of the most critical variables in the entire sintering process.

Sintering temperature is not a fixed material property but a crucial process parameter that you must control. The optimal temperature represents a strategic trade-off between achieving the desired density, controlling the material's final microstructure, and managing production cost and time.

The Role of Temperature in the Sintering Process

To understand why this temperature is so important, we must look at what happens on a microscopic level. Sintering is fundamentally about reducing the surface energy of a collection of particles by transforming them into a solid bulk material.

From Powder to Solid: The Atomic-Level Mechanism

Heat provides the thermal energy required for atoms to move, or diffuse, across the boundaries of adjacent particles. This atomic movement closes the pores between particles, causing them to fuse and the overall part to shrink and densify.

This process is distinct from melting. Think of it like pressing loose snowflakes together to form a solid piece of ice; the flakes bond without ever turning into water. In sintering, heat provides the energy for this bonding to occur.

Achieving Density and Strength

Generally, higher sintering temperatures accelerate the rate of atomic diffusion. This leads to faster pore elimination and results in a final product with higher density and greater mechanical strength.

The Problem of Grain Growth

However, excessive heat causes a competing phenomenon: grain growth. While particles are fusing, the individual crystal structures (grains) within the material also tend to grow larger. Overly high temperatures can lead to large, coarse grains, which often reduces the material's toughness and can make it more brittle.

Why Sintering Temperature Is a Process Variable

The ideal sintering temperature is not a single number you can look up in a textbook. It is highly dependent on the material, the manufacturing goals, and the specific method being used.

Influence of Material Composition

Different classes of materials have vastly different sintering temperature ranges. Metals typically sinter at lower temperatures than advanced ceramics like silicon carbide, which require very high heat to initiate diffusion.

Impact of Sintering Method

The way heat is applied dramatically influences the required temperature profile.

- Reaction Sintering utilizes a chemical reaction within the powder compact to aid the bonding process. This allows for densification at a significantly lower sintering temperature, reducing energy costs and making it suitable for large, complex structures.

- Microwave Sintering heats the material internally rather than from an external source. This can be much faster and more energy-efficient but is often limited to smaller parts and specific materials that couple well with microwaves.

The Role of Particle Size and Additives

Smaller starting particles have higher surface energy, which provides a greater driving force for sintering. As a result, finer powders can often be densified at lower temperatures. Additives can also be introduced to the powder to accelerate diffusion or pin grain boundaries, preventing excessive growth.

Understanding the Trade-offs

Selecting a sintering temperature is always an exercise in balancing competing factors. There is no single "best" temperature, only the one that is optimal for your specific objective.

Temperature vs. Time

You can often achieve a similar level of densification by heating at a lower temperature for a longer duration, or at a higher temperature for a shorter time. This relationship is critical for optimizing production throughput and energy consumption.

Density vs. Grain Size

This is the classic sintering dilemma. The goal is typically to achieve maximum density while maintaining the smallest possible grain size. This requires precise control over not just the peak temperature but the entire heating and cooling cycle.

Performance vs. Cost

Higher temperatures require more energy and more advanced, expensive furnaces. Methods like Reaction Sintering are attractive precisely because their lower temperature requirements can lead to a significant reduction in production costs without sacrificing performance for certain applications.

Selecting the Right Sintering Strategy

Your choice of sintering temperature should be directly guided by the intended properties of the final component.

- If your primary focus is maximizing density and strength: You will likely need to operate near the upper end of the material's sintering range, with precise control to prevent runaway grain growth.

- If your primary focus is preserving a fine-grained microstructure: Prioritize lower sintering temperatures, finer starting powders, and potentially advanced methods like microwave sintering to limit grain growth.

- If your primary focus is cost-effective production of large parts: Investigate methods like Reaction Sintering that operate at lower temperatures to minimize energy costs and thermal stresses.

Mastering the sintering temperature is not just about hitting a number; it's about strategically controlling energy to transform powder into performance.

Summary Table:

| Factor | Influence on Sintering Temperature |

|---|---|

| Material Type | Metals require lower temperatures than ceramics like silicon carbide. |

| Sintering Method | Reaction sintering uses lower temperatures; microwave sintering can be faster. |

| Particle Size | Finer powders can often be sintered at lower temperatures. |

| Goal (Density vs. Grain Size) | Higher temperatures increase density but can lead to larger, weaker grains. |

Ready to optimize your sintering process for superior results?

At KINTEK, we specialize in providing the precise lab equipment and expert support you need to master temperature control for your powdered materials. Whether you're working with metals, ceramics, or advanced composites, our furnaces and consumables are designed to help you achieve the perfect balance of density, strength, and microstructure.

Let our team help you select the right equipment to meet your specific performance and cost goals. Contact KINTEK today to discuss your laboratory's sintering needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- What is sintering reaction? Transform Powders into Dense Solids Without Melting