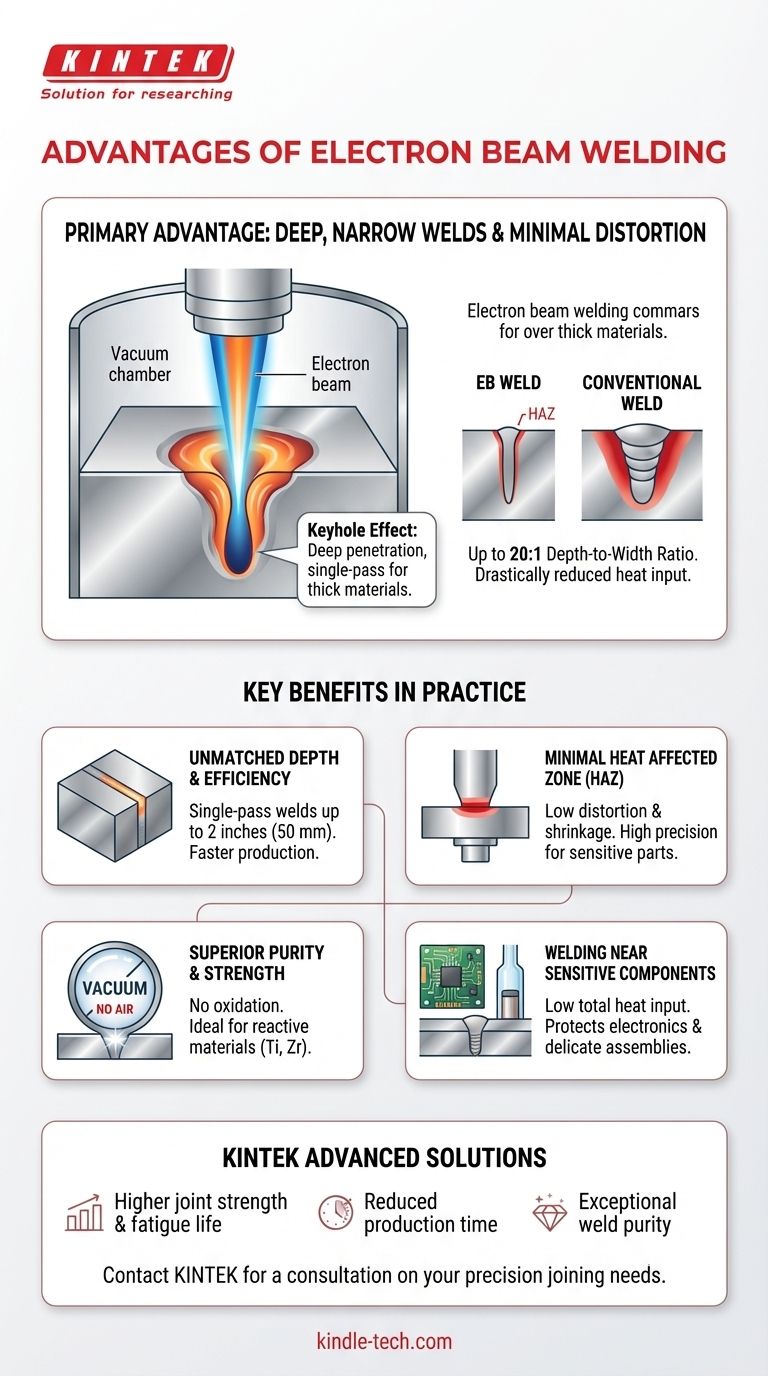

The primary advantage of electron beam welding is its ability to produce exceptionally deep, narrow welds with minimal heat distortion. It achieves this by using a tightly focused beam of high-velocity electrons in a vacuum, concentrating immense energy onto a tiny spot. This allows for single-pass welding of thick materials that would otherwise require multiple passes, complex preparation, and significant heat input with conventional methods.

Electron Beam (EB) welding trades the complexity of a vacuum environment for unparalleled control. This results in a high-power-density process that delivers deep, clean welds with minimal thermal damage to the surrounding material, a feat often unachievable with other methods.

The Physics of High Power Density

To understand the advantages of EB welding, you must first understand its fundamental principles. The process is defined by its use of a high-energy electron beam and a vacuum environment.

The Role of the Electron Beam

An electron gun generates and accelerates a stream of electrons to extremely high speeds, typically 50-70% the speed of light. Magnetic lenses then focus this stream into a very fine, high-energy beam.

This concentration of energy is the source of EB welding’s unique capabilities.

The Necessity of the Vacuum

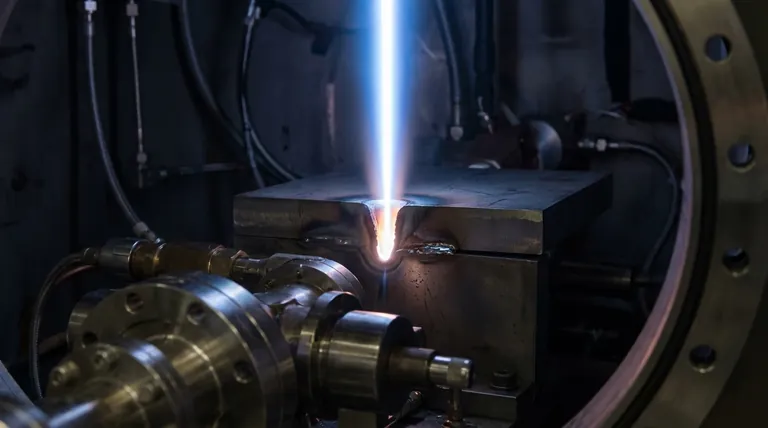

The entire process takes place inside a vacuum chamber. The vacuum is critical for two reasons.

First, it prevents the electrons from colliding with air molecules, which would scatter the beam and dissipate its energy. The vacuum ensures the beam remains focused and delivers its full power to the workpiece.

Second, the vacuum acts as a perfect shield, protecting the molten weld pool from atmospheric contaminants like oxygen and nitrogen, which can cause defects and weaken the joint.

Creating the "Keyhole" Effect

When the high-energy beam strikes the material, it instantly vaporizes a small column of metal. This creates a deep, narrow cavity known as a keyhole.

The beam penetrates deep into the material through this keyhole. As the beam moves along the joint, the molten metal flows around the keyhole and solidifies behind it, forming a very deep and narrow weld.

Key Advantages in Practice

The physics of the process translate directly into significant manufacturing and design advantages.

Unmatched Depth-to-Width Ratio

The keyhole effect allows for weld penetrations of up to two inches (50 mm) in steel. The resulting weld is extremely narrow, often with a depth-to-width ratio of 20:1 or higher.

This eliminates the need for multiple passes required by arc welding processes, drastically reducing welding time and consumable usage for thick sections.

Minimal Heat Affected Zone (HAZ)

Because the energy is delivered so precisely and efficiently, the total heat input into the component is very low.

This results in a tiny Heat Affected Zone (HAZ)—the area of base material that has its microstructure altered by the heat. A small HAZ means minimal distortion, shrinkage, and loss of material strength.

Superior Purity and Strength

Welding within a vacuum prevents oxides and nitrides from forming in the weld pool. This produces an exceptionally clean, high-purity weld.

This is especially critical for reactive materials like titanium, zirconium, and niobium, as well as for applications demanding the highest possible joint strength and fatigue life.

Welding Near Sensitive Components

The low total heat input and minimal distortion allow for welding in close proximity to heat-sensitive components.

This includes glass-to-metal seals, electronics, pre-machined surfaces, or delicate assemblies that would be damaged or distorted by the higher heat of conventional welding.

Understanding the Trade-offs

No process is without limitations. The unique environment required for EB welding introduces specific constraints that must be considered.

The Vacuum Chamber Constraint

Parts must fit inside a vacuum chamber. This limits the maximum size of the workpiece and adds significant time to the process for pumping the chamber down to the required vacuum level.

Requirement for Precise Fit-Up

The focused energy beam requires parts to be designed with a very precise fit-up. Unlike some arc welding processes, EB welding cannot reliably fill large or inconsistent gaps.

X-Ray Generation

The interaction of high-energy electrons with the workpiece material generates X-rays. The vacuum chamber must be properly shielded with lead to protect operators, adding to the machine's complexity and cost.

High Initial Capital Cost

EB welding systems, with their high-voltage power supplies, electron guns, vacuum chambers, and CNC controls, represent a significantly higher capital investment than standard arc welding equipment.

Is Electron Beam Welding Right for Your Application?

Choosing this process depends entirely on whether its unique benefits solve your specific engineering challenge.

- If your primary focus is performance and precision: For critical applications in aerospace, medical implants, or defense where weld integrity and minimal distortion are non-negotiable, EB welding is often the superior choice.

- If your primary focus is joining thick sections in a single pass: EB welding's deep penetration can drastically reduce production time and distortion compared to multi-pass conventional welding, justifying its cost.

- If your primary focus is welding reactive or dissimilar materials: The clean vacuum environment makes EB welding ideal for joining materials like titanium, copper, or niobium that are difficult or impossible to weld cleanly with other methods.

- If your primary focus is cost-sensitivity on simple parts: For general fabrication where high precision is not required, the cost and cycle time of EB welding are likely prohibitive, and conventional methods are more suitable.

Ultimately, choosing electron beam welding is an investment in process control to achieve metallurgical results that other methods cannot.

Summary Table:

| Key Advantage | Key Benefit | Ideal For |

|---|---|---|

| Unmatched Depth-to-Width Ratio | Single-pass welds up to 2 inches deep | Joining thick sections efficiently |

| Minimal Heat Affected Zone (HAZ) | Low distortion and shrinkage | Precision components & sensitive assemblies |

| Superior Weld Purity | No oxidation in vacuum environment | Reactive materials (titanium, zirconium) |

| Low Total Heat Input | Protects nearby heat-sensitive parts | Electronics, glass-to-metal seals |

Need a welding solution that delivers precision and strength for your critical components?

At KINTEK, we specialize in advanced lab and manufacturing equipment, including electron beam welding systems. Our solutions are designed for industries like aerospace, medical, and defense, where weld integrity is paramount. We can help you achieve:

- Higher joint strength and fatigue life for demanding applications.

- Reduced production time by joining thick materials in a single pass.

- Exceptional weld purity for reactive and dissimilar metals.

Let our experts help you determine if electron beam welding is the right investment for your precision joining needs. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Laboratory Test Sieves and Sieving Machines

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition