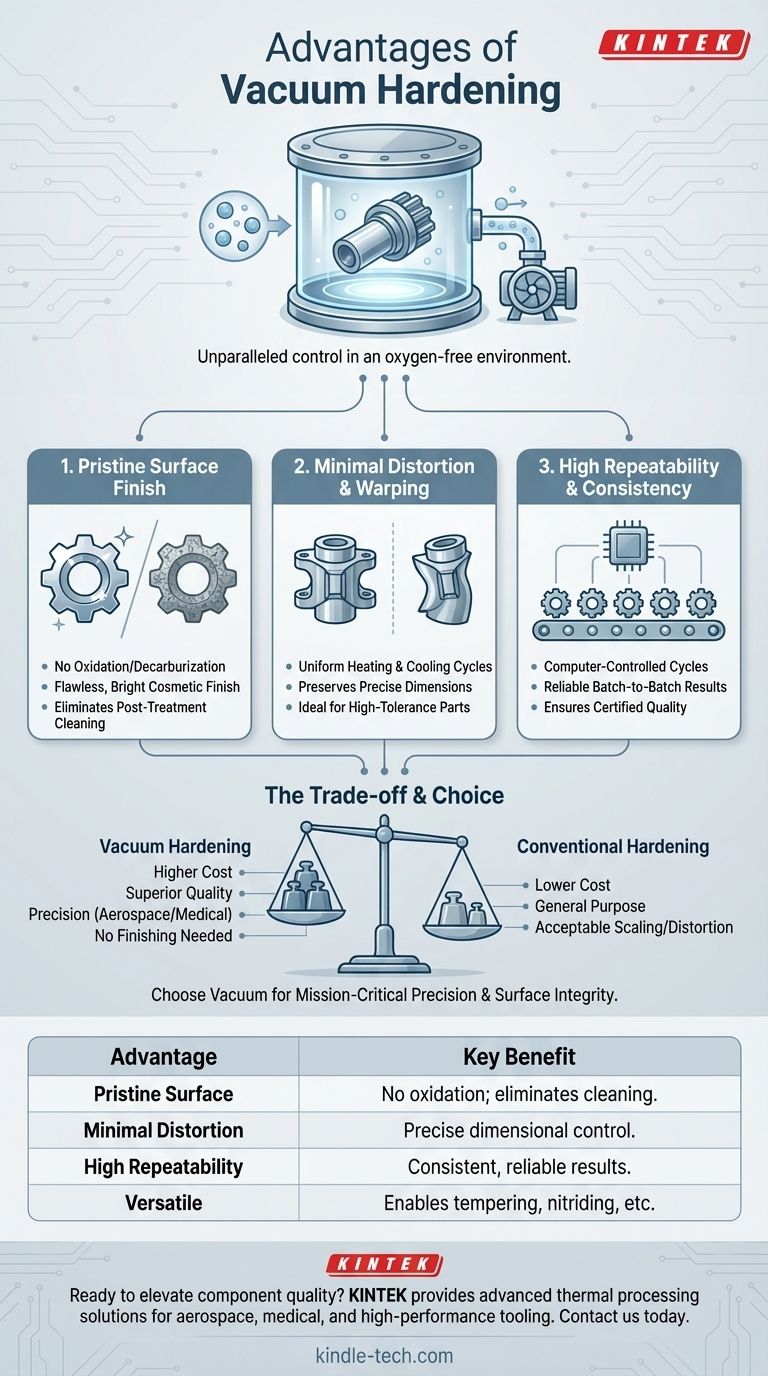

At its core, vacuum hardening offers unparalleled control over the heat treatment process. The primary advantages are a pristine, unoxidized surface finish, minimal distortion of the part's dimensions, and highly repeatable results. This is achieved by heating the metal in an oxygen-free vacuum, which prevents unwanted chemical reactions that occur in traditional, atmosphere-based hardening.

The decision to use vacuum hardening is not just about making a part harder. It is about achieving a level of precision, purity, and surface integrity that conventional methods cannot provide, often eliminating the need for costly and time-consuming secondary finishing operations.

The Core Principle: Removing Oxygen from the Equation

The defining feature of vacuum hardening is the environment in which the metal is heated. By removing air—and specifically oxygen—from the furnace, the process fundamentally changes the outcome of the heat treatment.

Preventing Oxidation and Decarburization

In a traditional furnace, the oxygen in the air reacts with the hot metal surface. This causes oxidation (scale) and can lead to decarburization, where carbon leaches out of the steel's surface, making it softer.

A vacuum furnace creates an oxygen-free environment, completely preventing these reactions. The integrity of the material's surface chemistry is perfectly preserved.

The Result: A Flawless Surface Finish

Because no scale or discoloration occurs, parts emerge from a vacuum furnace with a clean, bright, and often decorative metallic finish.

This is a significant advantage, as it frequently eliminates the need for post-treatment cleaning, grinding, or machining to remove a damaged surface layer. The part is essentially finished right out of the furnace.

Achieving Unmatched Precision and Consistency

For applications where dimensions are critical, such as in aerospace or medical devices, control is paramount. Vacuum hardening provides this control through both its environment and its technology.

Minimizing Distortion and Warping

Vacuum furnaces allow for extremely uniform and precisely controlled heating and cooling cycles. This consistency reduces internal stresses within the metal, which are the primary cause of distortion and warping during quenching.

The result is a hardened component that maintains its intended shape with minimal dimensional change, crucial for high-tolerance parts.

The Role of Computer Control

Modern vacuum furnaces are governed by sophisticated computer controls. This ensures that every part in a batch, and every subsequent batch, undergoes the exact same thermal cycle.

This high degree of repeatability guarantees consistent quality and is essential for industries that demand certified, reliable components.

Understanding the Trade-offs

While vacuum hardening offers superior results, it is not the universal solution for all applications. Understanding its limitations is key to making an informed decision.

The Primary Consideration: Cost

The equipment and process control required for vacuum hardening make it more expensive than conventional atmosphere-based heat treatment.

The higher upfront cost must be weighed against the savings from eliminated post-processing and the value of improved component quality and reliability.

When Conventional Hardening is Sufficient

For components where surface finish is not a cosmetic concern and slight dimensional changes are acceptable, traditional hardening methods are often more cost-effective.

These simpler processes are well-suited for general-purpose parts that do not require the precision and purity of a vacuum treatment.

The Spectrum of Vacuum Treatments

It's important to recognize that the vacuum furnace is a versatile tool. The same technology enables other advanced thermal processes like vacuum tempering, nitriding, and sintering, each offering unique benefits for enhancing wear resistance, corrosion resistance, or even creating porous materials.

Making the Right Choice for Your Application

The decision to use vacuum hardening should be driven by the final requirements of the component.

- If your primary focus is mission-critical precision (aerospace, medical, high-end tooling): The minimal distortion and high repeatability of vacuum hardening are non-negotiable for ensuring reliability and performance.

- If your primary focus is a perfect surface finish: Vacuum hardening provides a clean, bright surface that eliminates the need for secondary operations, saving time and money in the long run.

- If your primary focus is cost-effectiveness for general-purpose parts: A conventional heat treatment process is likely the more economical choice, provided minor scaling and distortion are acceptable.

Ultimately, choosing vacuum hardening is an investment in quality, precision, and a streamlined manufacturing process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Pristine Surface Finish | No oxidation or decarburization; eliminates need for post-treatment cleaning. |

| Minimal Distortion | Precise thermal control preserves part dimensions, ideal for high-tolerance components. |

| High Repeatability | Computer-controlled cycles ensure consistent, reliable batch-to-batch results. |

| Versatile Applications | Enables processes like tempering and nitriding for enhanced material properties. |

Ready to elevate your component quality with precision vacuum hardening? KINTEK specializes in advanced lab equipment and consumables, providing the reliable thermal processing solutions your laboratory needs. Our expertise ensures you achieve the flawless surfaces and dimensional accuracy required for aerospace, medical, and high-performance tooling applications. Contact us today to discuss how our solutions can streamline your manufacturing process and deliver superior results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost