At its core, the basic principle of an electric arc furnace (EAF) is to convert electrical energy into intense heat to melt metal. This is achieved by creating a high-power electric arc—a form of plasma discharge—that flows between graphite electrodes and the metallic material (the charge). This arc generates extreme temperatures, rapidly melting the metal without the need for traditional fuel combustion.

An electric arc furnace bypasses chemical combustion entirely. It uses the raw power of electricity to generate a controlled plasma arc, creating temperatures hot enough to melt steel and other metals with remarkable speed and efficiency.

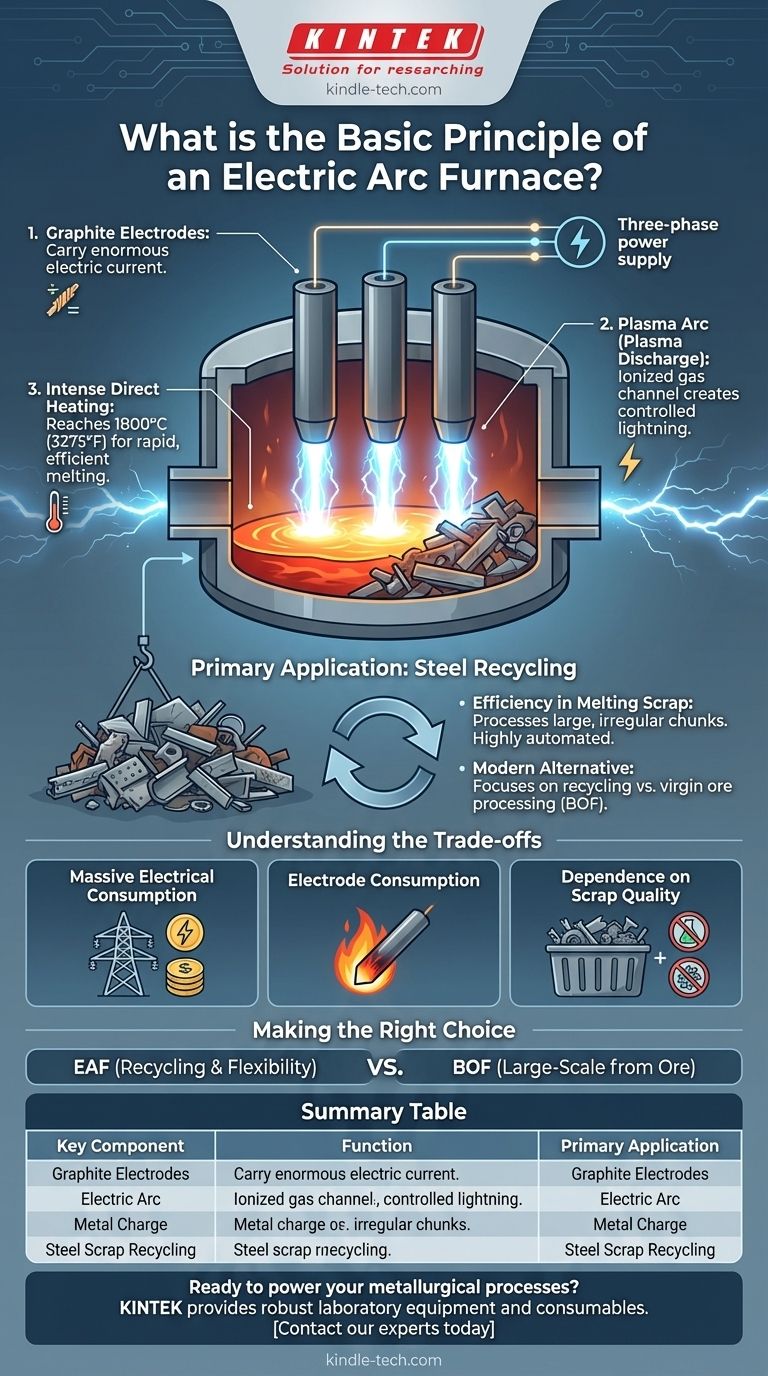

How an Electric Arc Generates Heat

The process is a direct application of electrical physics to achieve a metallurgical goal. It involves several key components working in sequence to deliver massive amounts of thermal energy precisely where it is needed.

The Role of Electrodes

An EAF typically uses three large, cylindrical graphite electrodes. These electrodes are connected to a powerful three-phase electrical supply.

They are positioned vertically above the metal charge inside the furnace. As conductors, their purpose is to carry the enormous electric current required to initiate and sustain the arc.

Creating the Plasma Arc

The process begins when the electrodes are lowered toward the metal charge. A very high voltage is applied, causing electricity to jump the gap between the electrode tips and the metal.

This discharge ionizes the gas in the gap, creating a channel of electrically conductive plasma. This stable, controlled lightning bolt is the electric arc.

Intense and Direct Heating

The plasma arc is incredibly hot, capable of reaching temperatures around 1800°C (3275°F).

This intense heat is transferred directly to the metal through radiation and conduction. Because the material is in direct contact with the arc, the energy transfer is extremely efficient and melting is very rapid.

The Primary Application: Steel Recycling

While versatile, the electric arc furnace has become the dominant technology for a specific and critical industrial process: recycling steel scrap.

Efficiency in Melting Scrap

EAFs are exceptionally well-suited for melting down scrap metal. Their ability to deliver immense heat quickly allows them to process large, irregular chunks of recycled steel that would be difficult to handle in other furnace types.

The process is highly automated, allowing operators to manage the melting cycle, add alloys, and refine the molten metal's chemistry with high precision.

A Modern Alternative to Ore Processing

The EAF process is often contrasted with the Basic Oxygen Furnace (BOF), which is primarily used to produce steel from iron ore (virgin material).

EAFs offer more flexibility, can be started and stopped more easily, and have a smaller footprint. This makes them the cornerstone of modern steel "mini-mills," which focus on recycling scrap into new steel products.

Understanding the Trade-offs

The EAF's efficiency comes with specific operational demands and limitations that are critical to understand.

Massive Electrical Consumption

An EAF is one of the largest electrical loads on any power grid. Operating a furnace requires a dedicated, high-capacity power supply, and electricity costs represent a major portion of the total operational expense.

Electrode Consumption

The graphite electrodes are not permanent. The intense heat of the arc and the chemical environment inside the furnace cause them to slowly burn away, or be "consumed."

These electrodes must be periodically replaced, adding a significant material cost to the steelmaking process.

Dependence on Scrap Quality

The final quality of the steel produced in an EAF is directly linked to the quality of the scrap metal used as input.

Contaminants in the scrap, such as copper, tin, or plastics, must be carefully managed. Poor quality scrap can lead to impurities in the final product, requiring additional refining steps that add time and cost.

Making the Right Choice for Your Goal

The EAF is a powerful tool, but its suitability depends entirely on the specific metallurgical objective.

- If your primary focus is recycling and flexibility: The EAF is the superior technology for melting scrap steel, offering fast batch processing and the ability to produce a wide range of steel grades.

- If your primary focus is large-scale production from iron ore: The traditional Basic Oxygen Furnace integrated with a blast furnace is generally the more established and economical pathway for virgin steel production.

- If your primary focus is energy and cost management: The viability of an EAF hinges on access to a stable and competitively priced high-voltage electricity supply.

The electric arc furnace fundamentally transformed modern metallurgy by turning electricity directly into a tool for melting and recycling.

Summary Table:

| Key Component | Function |

|---|---|

| Graphite Electrodes | Carry high current to create and sustain the electric arc. |

| Electric Arc (Plasma) | Generates extreme heat (up to 1800°C) for direct metal melting. |

| Metal Charge (Scrap) | The material to be melted, heated directly by the arc's radiation. |

| Primary Application | Dominant technology for efficient and flexible steel scrap recycling. |

Ready to power your metallurgical processes with precision?

At KINTEK, we specialize in providing robust laboratory equipment and consumables tailored for demanding applications. Whether you're involved in research, quality control, or process development involving high-temperature operations, our expertise can help you achieve greater efficiency and reliability.

Contact our experts today to discuss how KINTEK's solutions can meet your specific lab equipment needs and drive your projects forward.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a quartz tube in the preparation of Mo2Ga2C powder precursors? Essential Synthesis Benefits

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing