In essence, electron beam (e-beam) evaporation is a physical vapor deposition (PVD) technique that uses a focused, high-energy beam of electrons to heat a source material to the point of vaporization. This process takes place in a high-vacuum environment, allowing the vaporized material to travel in a straight line and condense onto a cooler substrate, forming a highly pure and uniform thin film.

The core principle of e-beam evaporation is converting the kinetic energy of electrons into intense thermal energy. This allows for the precise and efficient vaporization of a wide range of materials, including those with very high melting points, without contaminating the source.

A Step-by-Step Breakdown of the Process

To truly understand e-beam evaporation, we must look at the four distinct stages that transform a solid material in a crucible into a precise coating on a substrate.

Step 1: Generating Electrons

The process begins at a heated cathode, typically a filament made from a robust material like tungsten. This filament is heated to extreme temperatures (often over 2000°C), causing it to release a high flux of electrons through a process called thermionic emission.

Step 2: Acceleration and Focusing

Once freed, these electrons are accelerated by a high-voltage field. A system of powerful magnets then acts like a lens, shaping and focusing the accelerated electrons into a narrow, high-energy beam.

Step 3: Localized Heating and Evaporation

This focused electron beam is precisely directed onto the source material held within a crucible. The immense kinetic energy of the electrons is instantly converted to thermal energy upon impact, causing a very small, targeted area of the material to heat up rapidly and transition into a gas phase, or vapor.

Step 4: Deposition onto the Substrate

Inside the vacuum chamber, the vaporized atoms or molecules travel in a straight, unimpeded line. When they reach the cooler substrate (the object being coated), they condense back into a solid state, gradually building up a thin film.

The Critical Components and Their Roles

The effectiveness of the e-beam process hinges on several key components working in concert within a controlled environment.

The Electron Beam Source

This is the heart of the system, comprising the tungsten filament that emits electrons when heated and the high-voltage source that accelerates them.

The Magnetic Focusing System

Without this, the electrons would disperse randomly. The magnetic system is crucial for concentrating the energy into a small spot, enabling the high temperatures needed to vaporize even stubborn materials.

The Water-Cooled Crucible

The source material sits in a crucible, or hearth, which is actively water-cooled. This is a critical design feature. It ensures that only the material directly struck by the electron beam evaporates, preventing the crucible itself from melting and contaminating the source.

The Vacuum Chamber

The entire process must occur in a high-vacuum chamber. This serves two purposes: it prevents the hot filament from oxidizing, and it provides a clear, "line-of-sight" path for the vapor to travel from the source to the substrate without colliding with air molecules.

Understanding the Trade-offs

While powerful and precise, e-beam evaporation is not a universal solution. Understanding its inherent limitations is key to using it effectively.

The "Line-of-Sight" Limitation

Because the vapor travels in a straight line from the source to the substrate, e-beam evaporation is poorly suited for coating complex geometries or the inner surfaces of objects. Only the areas with a direct line of sight to the source will be coated.

Equipment Complexity and Cost

The need for high-voltage power supplies, powerful magnetic lenses, high-vacuum pumps, and sophisticated cooling systems makes e-beam evaporators complex and expensive pieces of equipment.

Inefficiencies and Byproducts

The high-energy electron interactions can produce secondary electron emissions and X-rays, which represent an energy loss and can potentially damage sensitive substrates.

Filament Degradation

The source filament operates under extreme conditions and will degrade over time. This can lead to inconsistent evaporation rates and requires periodic maintenance and replacement.

Making the Right Choice for Your Goal

Selecting the right deposition technique depends entirely on your material requirements, substrate geometry, and budget.

- If your primary focus is high-purity films or high-melting-point materials: E-beam evaporation is an excellent choice due to its precise, localized heating that prevents contamination.

- If your primary focus is coating complex, non-flat surfaces: You should consider alternative methods like sputtering, which do not have the same line-of-sight dependency.

- If your primary focus is wear resistance or specific optical properties on a flat surface: This process offers exceptional control for tailoring film properties for industries from electronics to aerospace.

Ultimately, understanding the core principle of energy transfer empowers you to leverage e-beam evaporation for its strengths while respecting its limitations.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Kinetic energy from electrons converted to thermal energy for vaporization |

| Key Advantage | High-purity films; can deposit high-melting-point materials |

| Main Limitation | Line-of-sight process, unsuitable for complex 3D geometries |

| Ideal For | Applications requiring precise, pure coatings on flat surfaces |

Ready to leverage e-beam evaporation for your high-purity coating needs? KINTEK specializes in advanced lab equipment and consumables, providing the reliable tools and expert support your laboratory requires to achieve superior thin film deposition. Whether you are developing next-generation electronics or aerospace components, our solutions are designed to meet your precise material requirements. Contact our experts today to discuss how we can enhance your deposition processes!

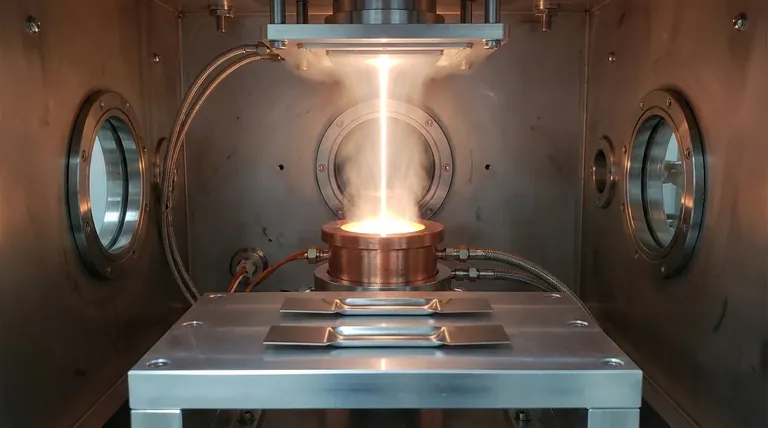

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition