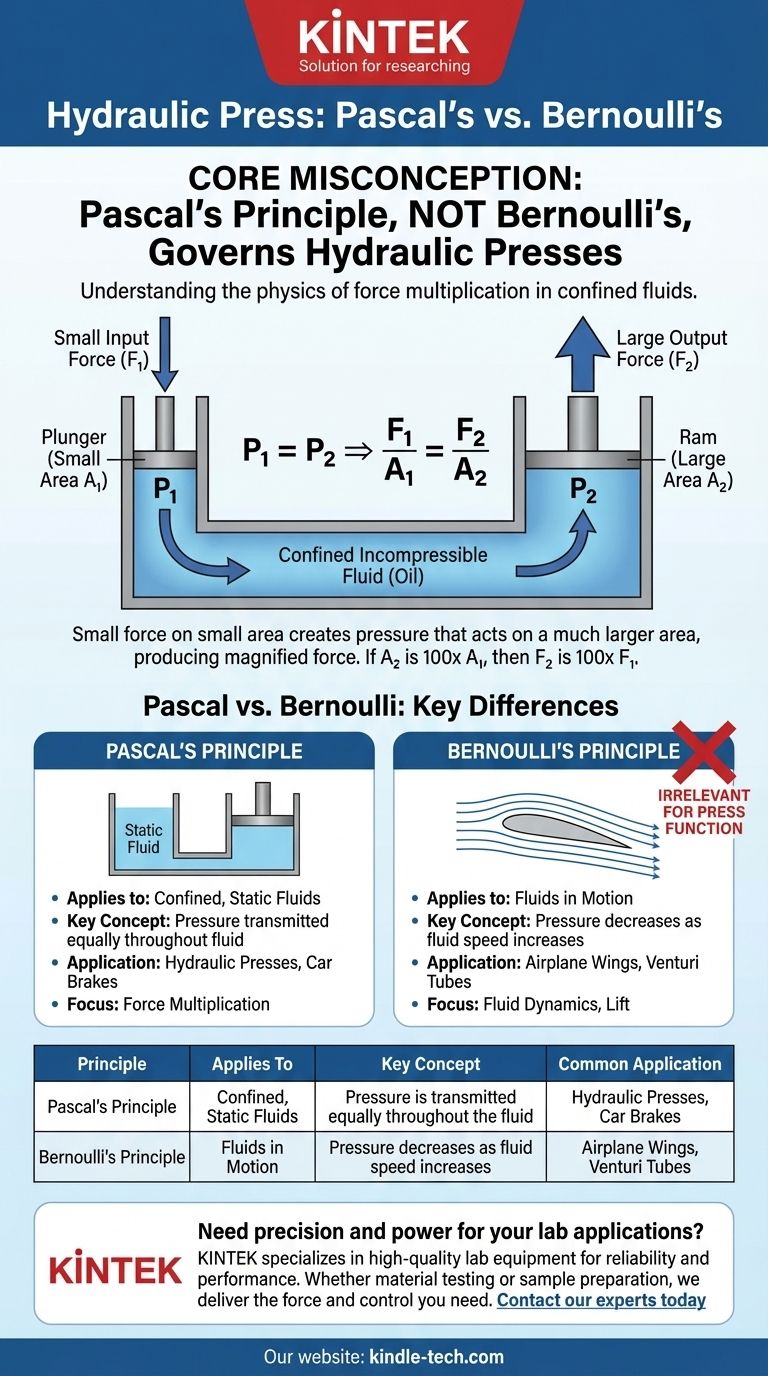

A hydraulic press operates on a fundamental principle of fluid mechanics, but it is Pascal's Principle, not Bernoulli's principle, that governs its function. This is a common point of confusion. The core mechanism of a hydraulic press relies entirely on how pressure is transmitted through a confined, incompressible fluid to multiply force, which is the domain of Pascal's Principle.

The central concept to grasp is this: A hydraulic press works by applying a small force to a small area to create pressure. According to Pascal's Principle, this pressure is transmitted equally throughout the fluid, acting on a larger area to generate a much larger output force.

The Core Mechanism: Understanding Pascal's Principle

To understand a hydraulic press, we must first understand the correct physical law that makes it possible. This law explains how simple fluid pressure can be leveraged to create immense mechanical force.

What is Pascal's Principle?

Pascal's Principle (also known as Pascal's Law) states that a pressure change at any point in a confined, incompressible fluid is transmitted equally throughout the fluid.

In simpler terms, if you apply pressure to one part of a sealed container of liquid, that same pressure is felt everywhere within that liquid.

How This Creates Force Multiplication

A hydraulic press uses two connected cylinders, each sealed with a piston, filled with a fluid like oil. One cylinder has a small-diameter piston (the plunger), and the other has a large-diameter piston (the ram).

When you apply a small downward force on the plunger, you create pressure in the fluid. Because this pressure is transmitted equally everywhere, it pushes up on the much larger ram with the same pressure.

Since pressure is defined as Force / Area, the output force on the ram is the pressure multiplied by the ram's area. Because the ram's area is significantly larger than the plunger's, the output force is magnified proportionally.

Deconstructing the Hydraulic Press

The elegance of the hydraulic press lies in its simple components working together based on this single principle.

Key Components

The system consists of two primary pistons: the plunger (small piston) where the initial force is applied, and the ram (large piston) that delivers the magnified output force.

These pistons are connected by a system filled with an incompressible fluid, most often a specialized hydraulic oil.

The Formula in Action

The relationship is captured by a straightforward equation based on Pascal's Law:

P₁ = P₂ which means F₁/A₁ = F₂/A₂

- F₁ is the small input force applied to the plunger.

- A₁ is the surface area of the plunger.

- F₂ is the large output force exerted by the ram.

- A₂ is the surface area of theram.

This formula clearly shows that if A₂ is 100 times larger than A₁, the output force F₂ will be 100 times greater than the input force F₁.

Clarifying the Misconception: Pascal vs. Bernoulli

It is critical to distinguish between these two fundamental principles of fluid mechanics, as they describe very different phenomena.

Pascal's Principle: Statics and Confined Fluids

Pascal's Principle applies to static fluids in a confined space. Its primary application is the multiplication of force. It is the foundational law for hydraulic systems like presses, car brakes, and construction equipment.

Bernoulli's Principle: Dynamics and Moving Fluids

Bernoulli's Principle applies to fluids in motion. It describes the inverse relationship between a fluid's speed and its pressure. As the speed of a moving fluid increases, its internal pressure decreases. This is the principle that explains how an airplane wing generates lift.

Why They Are Not Interchangeable

The key difference is motion. A hydraulic press primarily functions when the fluid is static or moving very slowly, transmitting pressure. Bernoulli's principle is irrelevant here because it governs the behavior of fluids at varying speeds.

Key Principles to Remember

To apply this knowledge correctly, focus on the distinct purpose of each physical law.

- If your primary focus is how force is multiplied: Remember that a small force on a small area creates pressure that, when applied to a larger area, results in a much larger output force.

- If your primary focus is the underlying law: The governing law is Pascal's Principle, which states that pressure is transmitted equally and undiminished throughout a confined fluid.

- If your primary focus is distinguishing the physics: Associate Pascal's Principle with static, confined fluids (like in a press) and Bernoulli's Principle with moving fluids (like air over a wing).

Understanding this core distinction is the key to grasping the elegant power of hydraulic systems.

Summary Table:

| Principle | Applies To | Key Concept | Common Application |

|---|---|---|---|

| Pascal's Principle | Confined, Static Fluids | Pressure is transmitted equally throughout the fluid | Hydraulic Presses, Car Brakes |

| Bernoulli's Principle | Fluids in Motion | Pressure decreases as fluid speed increases | Airplane Wings, Venturi Tubes |

Need precision and power for your lab applications? The principles of hydraulics are fundamental to many laboratory processes. At KINTEK, we specialize in high-quality lab equipment and consumables designed for reliability and performance. Whether your work involves material testing, sample preparation, or custom fabrication, our solutions are engineered to deliver the force and control you need. Contact our experts today to discuss how we can support your specific laboratory requirements.

Visual Guide

Related Products

- Manual Lab Heat Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- What is press in industry? A Guide to Mechanical, Hydraulic & Servo Presses

- What is hydraulic press forging? Achieve Precise Control and Superior Strength for Large Metal Parts

- Why is a laboratory hydraulic press essential for dry electrode films? Unlock High-Loading Battery Innovation

- What are the factors that determine the quality of pellets? Maximize Heat and Minimize Maintenance

- What are 3 uses of a hydraulic press? Discover Force Multiplication for Industry & Science

- What does XRF measure? Uncover Elemental Composition for Materials Analysis

- What are the advantages of a power press? High-Speed, High-Volume Manufacturing Solution

- Does temperature affect hydraulic fluid? The Critical Role of Heat in System Performance