The best crucible for melting metal is the one correctly matched to your specific metal, furnace type, and scale of operation. There is no single "best" material, but rather a best fit for your task. For most hobbyists and small foundries melting non-ferrous metals like aluminum or brass, a clay-graphite crucible is the ideal starting point, while professionals melting hotter metals or requiring longer service life will choose silicon carbide.

Choosing a crucible isn't about finding one superior product. It is an engineering decision based on three critical factors: the melting point of your metal, the type of heat your furnace produces, and the longevity you require versus your budget.

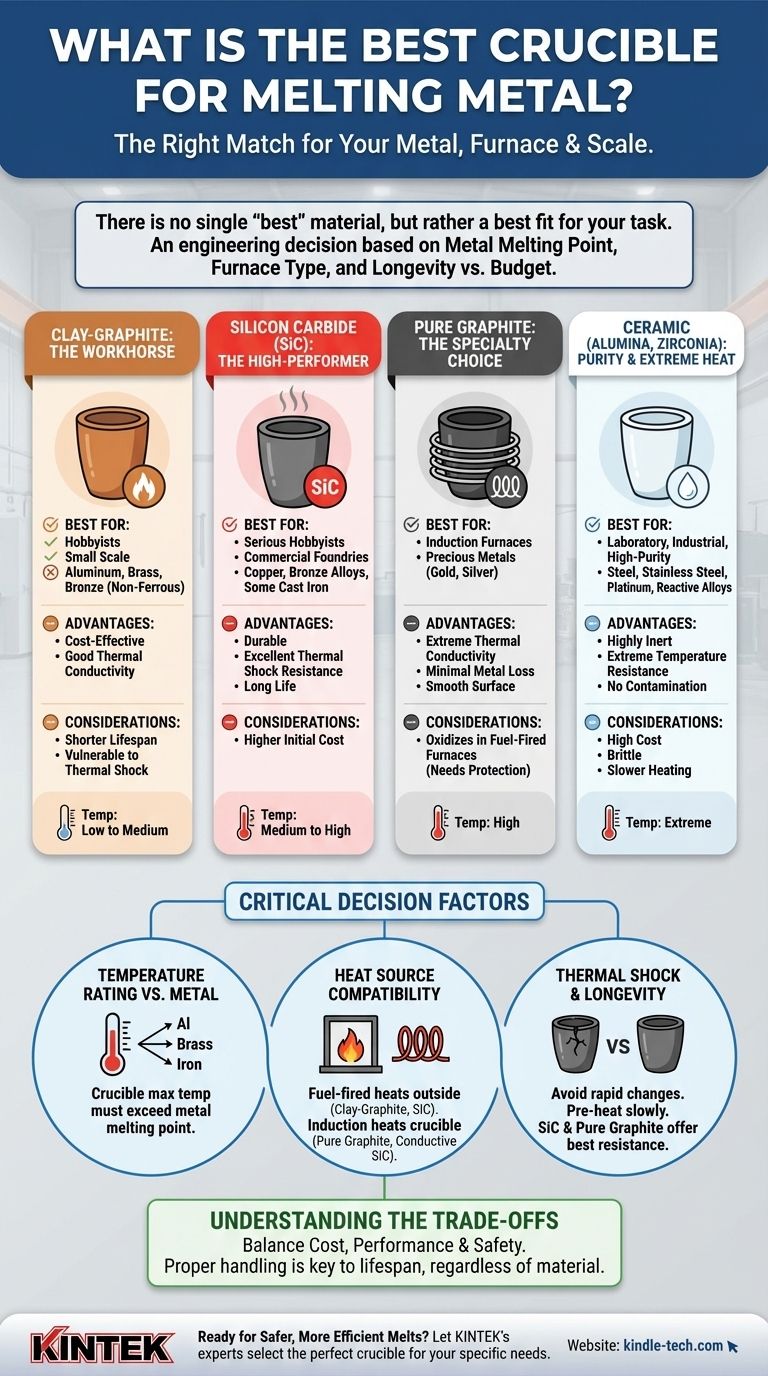

Matching Crucible Material to Your Needs

The material of the crucible dictates its performance, lifespan, and cost. Understanding the primary types is the first step in making an informed decision.

Clay-Graphite: The Workhorse

Clay-graphite crucibles are the most common and cost-effective choice for hobbyists and small-scale operations. They are made from a mixture of flake graphite and ceramic clays.

They provide good thermal conductivity and are perfectly suited for lower-temperature, non-ferrous metals like aluminum, brass, and bronze.

While affordable, they have a shorter lifespan than more advanced materials and are more susceptible to damage from mishandling or rapid temperature changes.

Silicon Carbide (SiC): The High-Performer

Silicon carbide crucibles are a significant step up in performance and durability. They are denser, stronger, and have superior thermal conductivity compared to clay-graphite.

This makes them the standard for serious hobbyists and commercial foundries. They can handle the higher temperatures required for copper and bronze alloys with ease and can even be used for some cast iron work.

SiC crucibles have excellent resistance to thermal shock, meaning they are less likely to crack when heated and cooled. This durability results in a much longer service life, justifying their higher initial cost.

Pure Graphite: The Specialty Choice

Pure graphite crucibles are machined from a solid block of high-density graphite. Their primary advantage is extreme thermal conductivity and resistance to thermal shock.

They are the preferred choice for induction furnaces, which heat the crucible material directly. They are also excellent for working with precious metals like gold and silver, as their smooth surface minimizes metal loss.

However, pure graphite will oxidize and degrade in a fuel-fired furnace (propane or gas) if not protected by a special coating or inert gas blanket.

Ceramic: For Purity and Extreme Heat

Ceramic crucibles, made from materials like alumina or zirconia, are used in laboratory and industrial settings where metal purity is the absolute priority.

They are highly inert and will not contaminate the melt, which is critical for reactive metals or aerospace alloys. They can also withstand extremely high temperatures, making them suitable for steel, stainless steel, and platinum.

Their main drawbacks are high cost, lower thermal conductivity (slower melts), and extreme brittleness, making them fragile and difficult to handle.

Critical Factors Beyond Material

Beyond the base material, you must consider how the crucible interacts with your specific process.

Temperature Rating vs. Your Metal

This is the most important factor. Always ensure your crucible's maximum service temperature is well above the melting point of the metal you are working with.

- Aluminum (Melts at ~1220°F / 660°C): A clay-graphite crucible is perfectly adequate.

- Brass/Bronze (Melts at ~1700°F / 930°C): Clay-graphite can work, but a silicon carbide crucible is a safer and more durable choice.

- Cast Iron (Melts at ~2200°F / 1200°C): A high-quality silicon carbide or ceramic crucible is required.

Heat Source Compatibility

Your furnace type dictates the best crucible choice.

A fuel-fired furnace (propane, gas, waste oil) heats the crucible from the outside. Both clay-graphite and SiC are designed for this environment.

An induction furnace heats the crucible itself via an electromagnetic field. Pure graphite and specialized conductive silicon carbide crucibles are designed to work efficiently with this method.

The Importance of Thermal Shock

Thermal shock is the stress a material endures when its temperature changes rapidly. A low-quality or misused crucible can crack or fail catastrophically.

Always pre-heat your crucible slowly before the first melt and before each subsequent use. This drives out any absorbed moisture, which can turn to steam and destroy the crucible. Silicon carbide and pure graphite offer the best resistance to this type of failure.

Understanding the Trade-offs

Choosing a crucible is a balance of cost, performance, and safety. There is no perfect solution, only the right one for your goal.

Cost vs. Lifespan

A clay-graphite crucible may cost a fraction of a silicon carbide one. However, if the SiC crucible lasts 10 times as long, it represents a better long-term investment for anyone melting metal frequently.

For the occasional hobbyist, a cheaper clay-graphite crucible is often the more practical financial choice.

Proper Handling is Non-Negotiable

An expensive crucible can be destroyed in a single melt if handled improperly. A cheap crucible, when cared for, can last for dozens of melts.

Always use tongs that fit the crucible correctly, store it in a dry place, and follow a strict pre-heating regimen. Operator skill is more important than material expense.

Contamination and Reactivity

For most projects, a tiny amount of contamination from a clay-graphite or SiC crucible is irrelevant.

However, when working with high-purity metals or reactive alloys, the crucible material itself can leach into the melt. In these cases, the high cost of an inert ceramic crucible is a necessary part of the process.

Making the Right Choice for Your Goal

Select your crucible based on a clear understanding of your objective.

- If your primary focus is melting aluminum or brass as a hobbyist: A clay-graphite crucible offers the best balance of cost and performance.

- If your primary focus is running a small foundry with frequent bronze or copper melts: Investing in a silicon carbide (SiC) crucible will provide a longer service life and greater safety.

- If your primary focus is working with high-temperature metals like cast iron: A high-quality silicon carbide crucible is the minimum requirement for safety and effectiveness.

- If your primary focus is using an induction furnace or melting precious metals: A pure graphite crucible is the most efficient and suitable choice.

- If your primary focus is achieving the highest purity for reactive metals: A pure ceramic crucible is necessary, despite the high cost and careful handling required.

By matching the tool to the task, you ensure safe, efficient, and successful melts every time.

Summary Table:

| Crucible Material | Best For | Key Advantages | Key Considerations |

|---|---|---|---|

| Clay-Graphite | Hobbyists; Aluminum, Brass, Bronze | Cost-effective, good thermal conductivity | Shorter lifespan, susceptible to thermal shock |

| Silicon Carbide (SiC) | Serious Hobbyists/Commercial; Copper, Bronze, Cast Iron | Durable, excellent thermal shock resistance, long service life | Higher initial cost |

| Pure Graphite | Induction Furnaces; Precious Metals (Gold, Silver) | Extreme thermal conductivity, minimal metal loss | Not for fuel-fired furnaces without protection |

| Ceramic (Alumina, Zirconia) | High-Purity/Reactive Metals; Steel, Platinum | Highly inert, extreme temperature resistance | High cost, brittle, slow heating |

Ready to achieve safer, more efficient metal melts? The right crucible is critical for your success. KINTEK specializes in high-performance lab equipment and consumables, including a full range of crucibles designed for specific metals and furnace types. Our experts can help you select the perfect crucible for your laboratory or foundry needs, ensuring optimal performance and longevity.

Contact our technical team today for a personalized recommendation and see how KINTEK can support your melting applications!

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

People Also Ask

- What is the temperature range of graphite crucible? Choose the Right Crucible for Your High-Temp Application

- What is the role of an alumina crucible in LLZ calcination? Ensure High Purity in Solid-State Electrolyte Synthesis

- Why must mullite or clay refractory containers be used with graphite lids? Protect Carbon Samples at 1000°C

- How to maintain a crucible? Prevent Thermal Shock and Ensure Longevity

- What can I use as a crucible to melt copper? Choose the right material for your furnace.

- What is the primary function of nickel crucibles in Li2OHCl synthesis? Ensure Purity & Chemical Inertness

- Why are transparent quartz crucibles utilized as containers for MAX phase precursors? Ensuring Visual Control & Purity

- What is a porcelain crucible? Your Essential Guide to High-Temp Lab Work