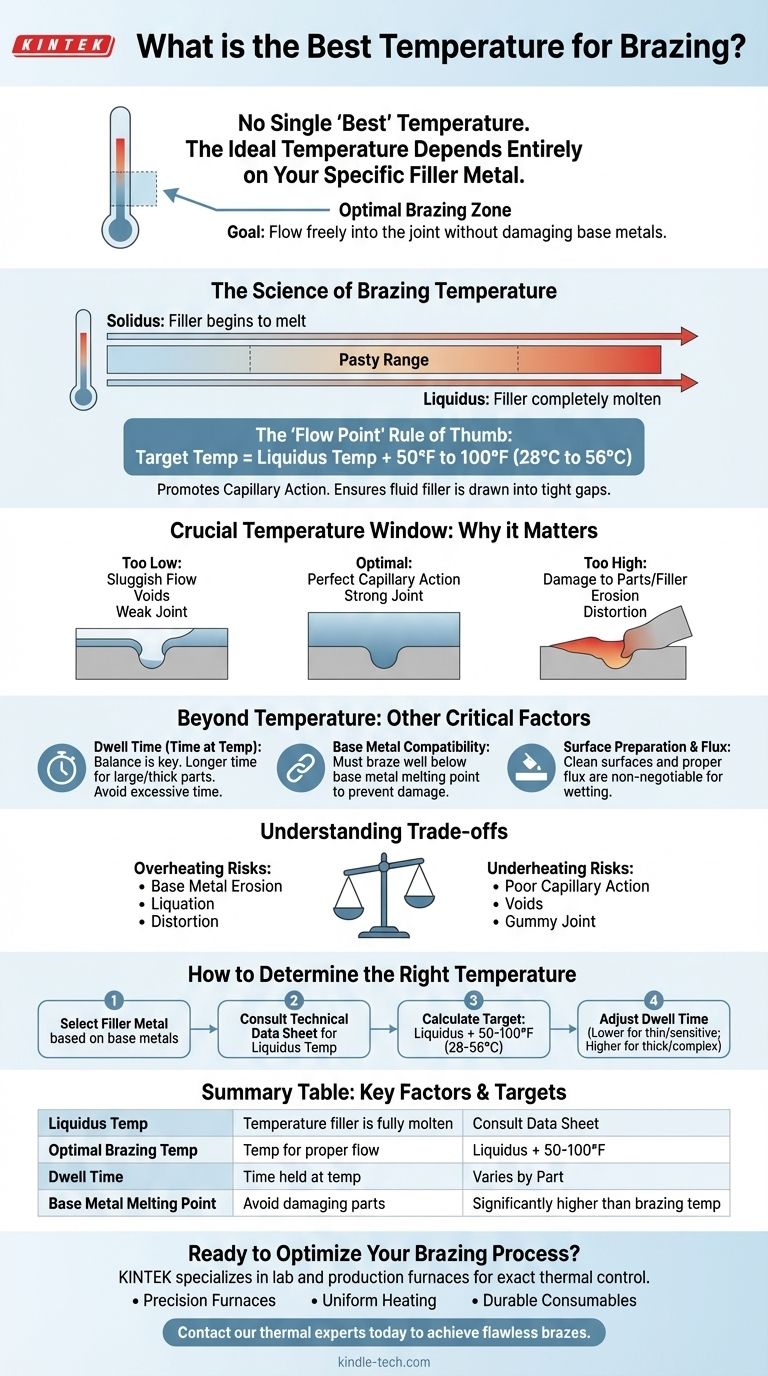

The short answer is there is no single "best" temperature for brazing. The ideal temperature is determined entirely by the specific filler metal you are using. Setting your equipment to a generic temperature without considering the filler alloy is the most common path to a failed joint.

The core principle of brazing is to heat the assembly to a temperature slightly above the point where the filler metal becomes fully liquid (its liquidus temperature). This ensures the filler flows freely into the joint via capillary action without damaging the base metals being joined.

The Science of Brazing Temperature

To achieve a successful braze, you must understand the properties of your chosen filler metal. The manufacturer's technical data sheet is your most critical resource, as it specifies the temperatures you must work with.

Solidus vs. Liquidus: The Critical Temperatures

Every brazing filler metal has two key temperature points:

- Solidus: The temperature at which the filler alloy begins to melt.

- Liquidus: The temperature at which the filler alloy is completely molten.

For some alloys, like eutectic alloys, the solidus and liquidus temperatures are the same. For most, there is a "pasty" or "slushy" range between the two.

The "Flow Point" Rule of Thumb

The proper brazing temperature is not the melting point, but a temperature above it. This ensures the filler is fluid enough to be drawn into the tight gaps of the joint.

As a universally accepted rule, the target brazing temperature should be set 50°F to 100°F (28°C to 56°C) above the filler metal's liquidus temperature.

Why This Temperature Window is Crucial

This specific window is essential for promoting capillary action, the force that pulls the molten filler into the joint.

If the temperature is too low (below this window), the filler will be sluggish and will not flow completely, resulting in voids and a weak joint. If it is too high, you risk damaging the parts or the filler itself.

Beyond Temperature: The Other Critical Factors

Achieving the right temperature is necessary, but not sufficient. A successful braze depends on a balance of several interconnected parameters.

Dwell Time: The Second Half of the Equation

The balance between time and temperature is critical. Dwell time is the amount of time the assembly is held at the target brazing temperature.

A longer dwell time can help ensure a large or thick part is heated uniformly and allows the filler to fully penetrate the joint. However, excessive time at temperature can be just as damaging as excessive heat.

Base Metal Compatibility

A fundamental rule of brazing is that the process must happen well below the melting point of the base metals you are joining.

The chosen brazing temperature must not distort, weaken, or otherwise damage the parent materials. This is a primary reason for choosing brazing over welding for certain applications.

The Role of Surface Preparation and Flux

Even with perfect temperature control, a braze will fail if the surfaces are not clean. Oxides, oils, and dirt prevent the filler metal from wetting the surface and flowing into the joint.

Proper cleaning and the correct use of brazing flux (or a controlled atmosphere) to prevent re-oxidation during heating are non-negotiable prerequisites for a good joint.

Understanding the Trade-offs

Choosing your brazing parameters always involves balancing competing factors. Understanding these trade-offs is the mark of a true expert.

The Risk of Overheating

Heating the assembly too far above the filler's liquidus temperature or for too long can cause several problems:

- Base Metal Erosion: The molten filler can begin to dissolve the base metal, weakening the joint.

- Liquation: In some alloys, lower-melting-point constituents can flow out while other parts remain solid, changing the filler's chemical composition.

- Distortion: Excessive heat can cause thin parts to warp.

The Problem with Underheating

Failing to reach the proper flow point temperature is a more common mistake and leads to immediate failure.

- Poor Capillary Action: The filler will be too viscous to be drawn into the joint.

- Voids and Incomplete Fill: The joint will have gaps, severely compromising its strength.

- A "Gummy" Joint: The filler may clump at the entrance to the joint without penetrating it.

How to Determine the Right Temperature for Your Project

Follow this process to ensure you are using the correct temperature every time. First, select your filler metal based on the base metals you are joining. Then, consult that filler's technical data sheet to find its liquidus temperature.

- If your primary focus is a standard, strong joint: Set your process temperature to be 50-100°F (28-56°C) above the filler metal's specified liquidus temperature.

- If you are working with thin or heat-sensitive materials: Aim for the lower end of that range (e.g., liquidus + 50°F) and minimize your dwell time to prevent part distortion.

- If you are brazing thick, dissimilar, or complex parts: You may need to use the higher end of the range (e.g., liquidus + 100°F) and a longer dwell time to ensure the entire assembly is uniformly heated.

By moving from asking for a single number to understanding the principles, you gain control over the entire brazing process.

Summary Table:

| Key Factor | Description | Target Range |

|---|---|---|

| Liquidus Temperature | The temperature at which the filler metal is fully molten. | Found on the filler metal's technical data sheet. |

| Optimal Brazing Temp | The temperature to set your furnace for proper flow. | Liquidus + 50°F to 100°F (28°C to 56°C) |

| Dwell Time | Time held at the brazing temperature. | Varies based on part size and complexity. |

| Base Metal Melting Point | Critical to avoid damaging the parts being joined. | Must be significantly higher than brazing temperature. |

Ready to Optimize Your Brazing Process?

Choosing the right temperature is just the beginning. Consistent, high-quality brazing requires reliable and precise equipment. KINTEK specializes in lab and production furnaces designed for exact thermal control, ensuring your brazing operations are repeatable and successful.

We provide the tools for perfection:

- Precision Furnaces: Achieve and maintain the exact temperatures your filler metals require.

- Uniform Heating: Eliminate cold spots that lead to weak joints.

- Durable Consumables: High-quality fixtures and insulation to protect your investment.

Stop guessing and start achieving flawless brazes. Contact our thermal experts today to find the perfect furnace solution for your laboratory or production needs.

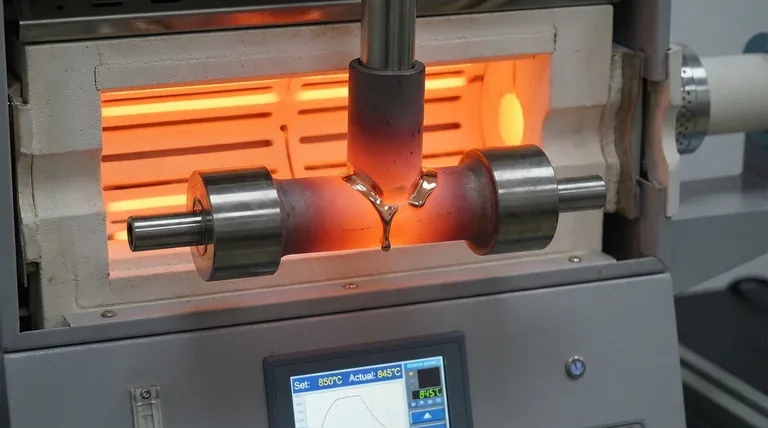

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- How accurate is XRF analysis? A Guide to Elemental Analysis Precision

- What are the advantages of pyrolysis plant? Turn Waste into Profit with Advanced Recycling

- What is the critical function of a high vacuum oven? Protect Solid-State Cathodes with Heat-Free Solvent Removal

- What is the desired range of chamber pressure to start the sputtering process? Optimize Your Deposition for Quality and Uniformity

- What role do high-pressure homogenizers or ultrasonic cell disrupters play in the mechanical processing of nanocellulose?

- Can aluminum be sputtered? Master the Process for High-Quality Thin Films

- What is physical vapor phase deposition? Achieve Superior Thin-Film Coatings for Your Components

- What temp is required for brazing? A Guide to Perfect Filler Metal Flow & Strong Joints