In short, the body of a furnace is a dual-layer structure designed for containment. It consists of a strong, rigid outer shell—typically made of welded steel—that provides mechanical support, and a specialized inner lining made of refractory materials that can withstand extreme heat and insulate the outer shell. This layered approach is the fundamental principle behind nearly all furnace construction.

The core challenge of furnace design is to safely contain and control immense thermal energy. The solution is not a single material, but a system: a structural outer shell protects and supports a heat-resistant inner lining, with integrated systems for heating, cooling, and access tailored to the furnace's specific purpose.

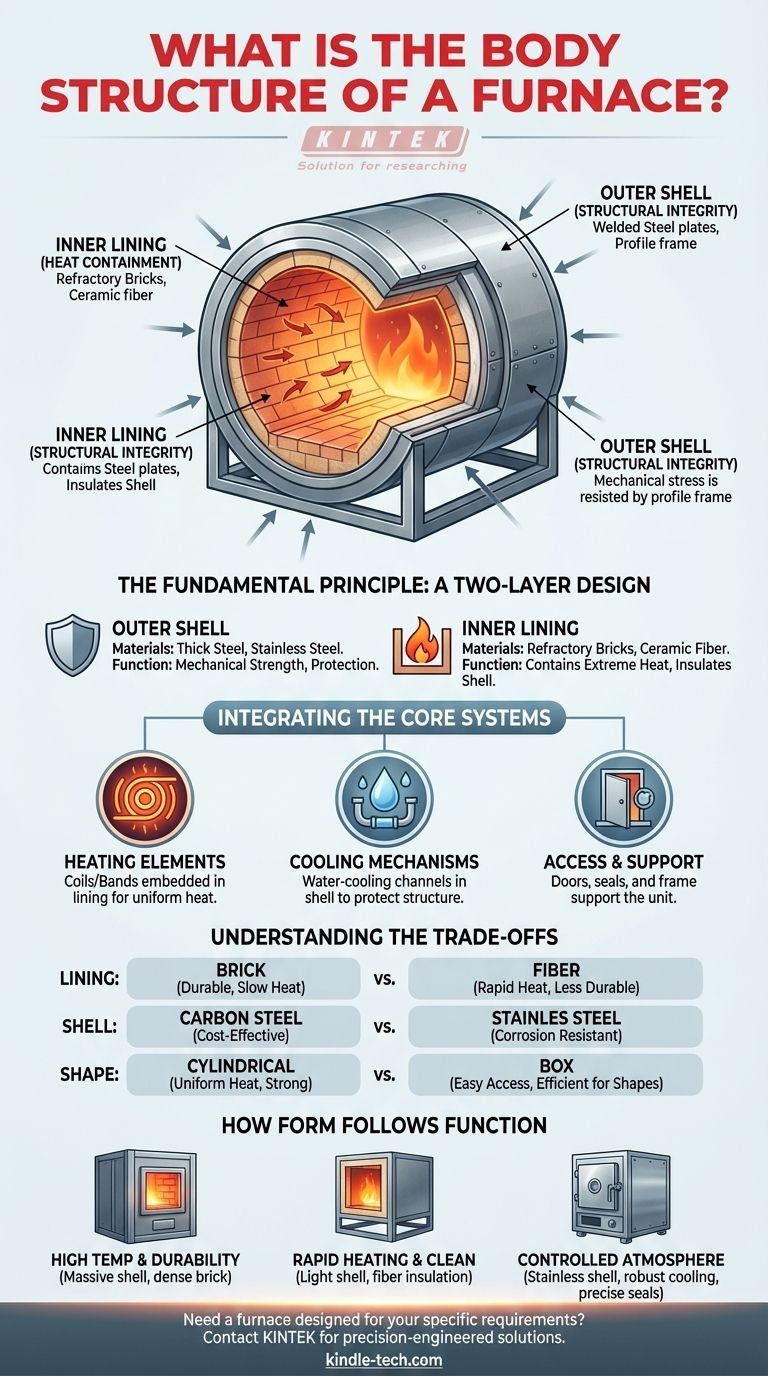

The Fundamental Principle: A Two-Layer Design

At its heart, a furnace body solves two distinct problems: providing structural integrity and withstanding extreme temperatures. This is achieved by assigning these roles to two different layers.

The Outer Shell: Structural Integrity and Protection

The outer layer, or shell, is the furnace's skeleton. It provides the mechanical strength needed to hold the entire assembly together.

This shell is typically fabricated from thick steel plate, often welded to a steel profile frame. In applications requiring corrosion resistance or vacuum purity, stainless steel is the material of choice.

The shell's primary job is to resist physical stress. This includes the weight of the furnace itself, forces from loading mechanisms, and any internal pressure. It must maintain its shape and stiffness without deforming, even when the interior is at peak temperature.

The Inner Lining: Containing Extreme Heat

Inside the shell is the refractory lining, which forms the heating chamber or "hot zone." This is the layer that directly faces the intense heat.

This lining is made from refractory materials—specialized ceramics designed to have very high melting points and low thermal conductivity. Common examples include silica bricks, magnesite blocks, or alumina ceramic fiber.

The refractory material serves two critical functions: it contains the heat within the furnace and insulates the outer steel shell, preventing it from overheating and losing its structural strength.

Integrating the Core Systems

The furnace body is not just a passive container; it is an active system with critical components integrated directly into its structure.

The Heating Chamber and Elements

The heating elements, such as coils or bands, are typically embedded within or wrapped around the refractory lining. This placement ensures that heat is generated and distributed evenly throughout the chamber for uniform processing.

Essential Cooling Mechanisms

Counterintuitively, cooling is a vital part of a high-temperature furnace body. Water-cooling channels are often built directly into the steel shell, doors, and areas around seals or electrodes.

This active cooling is necessary to protect structural components, prolong the life of seals, and ensure a sharp temperature gradient between the hot interior and the safe exterior.

Access, Sealing, and Support

The body incorporates all necessary access points, such as doors or removable "bell jar" tops. For vacuum or controlled-atmosphere furnaces, these openings feature precisely engineered seals.

The entire furnace body is often mounted on a console or frame that also supports the vacuum pumps, gas manifolds, and control systems, creating a single, integrated unit.

Understanding the Trade-offs

The specific construction of a furnace body involves critical engineering trade-offs based on its intended application, temperature range, and budget.

Refractory Lining: Brick vs. Fiber

Dense refractory bricks (like silica or magnesite) offer excellent durability and chemical resistance, making them ideal for heavy industrial processes like metal melting. However, they have high thermal mass, meaning they heat and cool slowly.

Ceramic fiber insulation is lightweight and has low thermal mass, allowing for very rapid heating and cooling cycles. This makes it perfect for laboratory and testing furnaces, but it is generally less durable than brick.

Shell Material: Carbon Steel vs. Stainless Steel

A standard carbon steel shell is strong and cost-effective for most air-atmosphere furnaces.

Stainless steel is used when corrosion resistance is needed or in high-vacuum applications where outgassing from the shell material must be minimized to maintain a pure environment.

Design Shape: Cylindrical vs. Box

Cylindrical bodies, including tube furnaces, offer inherent structural strength and promote uniform heating, making them ideal for many high-pressure and high-temperature applications.

Box or rectangular chambers provide easier access and are more efficient for processing large, flat, or awkwardly shaped parts.

How Form Follows Function in Furnace Design

The structure of a furnace body is dictated entirely by its job. By observing its construction, you can infer its purpose.

- If your primary focus is maximum temperature and durability (e.g., steelmaking): Expect to see a massive, thick-walled steel shell lined with dense, heavy refractory bricks to withstand the thermal and mechanical stress.

- If your primary focus is rapid heating in a clean environment (e.g., lab research): You will find a lighter shell, often hinged for easy access, with ceramic fiber insulation and a quartz or alumina process tube.

- If your primary focus is a controlled vacuum or special atmosphere: Look for a precisely machined stainless steel body with robust water-cooling channels and complex flanges for vacuum-tight sealing.

Ultimately, every element of a furnace body is a deliberate engineering choice designed to control and contain extreme thermal energy safely and effectively.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Outer Shell | Welded steel (carbon or stainless) | Provides structural integrity and mechanical support |

| Inner Lining | Refractory materials (brick, ceramic fiber) | Withstands extreme heat and insulates the outer shell |

| Heating Elements | Coils or bands embedded in lining | Generates and distributes heat evenly |

| Cooling System | Water-cooling channels in shell | Protects structural components and seals |

Need a furnace designed for your specific thermal processing requirements?

At KINTEK, we specialize in laboratory equipment and consumables, crafting furnaces with precision-engineered bodies tailored to your application—whether for rapid heating in research or durable, high-temperature industrial use. Our expertise ensures optimal performance, safety, and efficiency.

Contact us today to discuss how KINTEK's solutions can enhance your lab's capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the purpose of a muffle furnace? Achieve High-Purity Heating for Your Lab

- What should be considered when performing melting point determination? Ensure Accurate Compound Identification and Purity Assessment

- How do you measure ash content? Choose the Right Method for Accurate Results

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- How is melting point affected by heating rate? Avoid Inaccurate Measurements in Your Lab