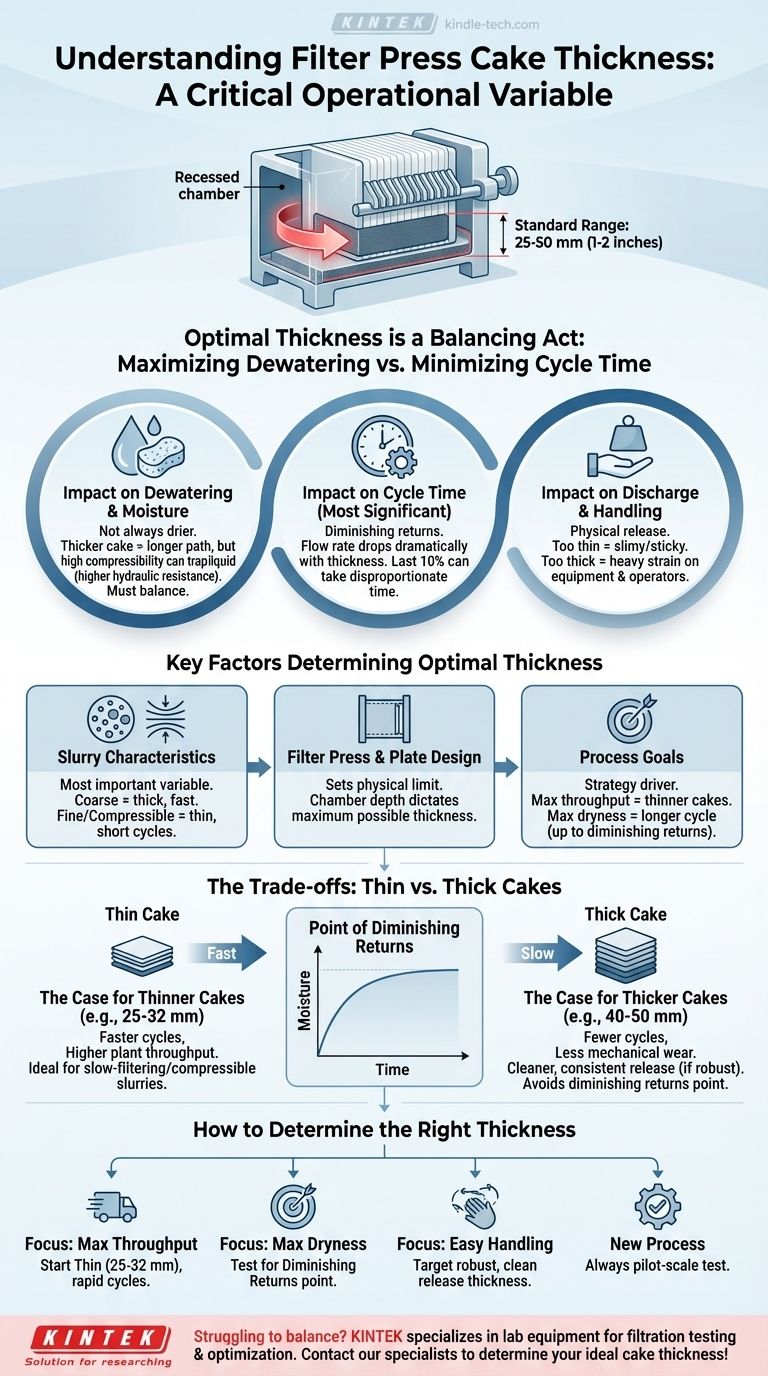

In a standard recessed chamber filter press, the filter cake thickness typically ranges from 25 mm to 50 mm (approximately 1 to 2 inches). This thickness is determined by the chamber depth of the filter plates used in the press. While this provides a direct answer, the optimal cake thickness is not a fixed number but a critical operational variable that you must determine for your specific process.

The central challenge is not achieving a specific thickness, but rather understanding that cake thickness is a lever you pull to balance two competing goals: maximizing solids dewatering and minimizing the time it takes to complete a filtration cycle.

Why Cake Thickness is a Critical Process Variable

Filter cake thickness is not merely an outcome; it is a fundamental parameter that directly influences the efficiency, speed, and cost-effectiveness of your entire solid-liquid separation process.

Impact on Dewatering and Moisture Content

A common misconception is that a thicker cake always results in a drier product. While a thicker cake provides a longer path for the liquid to travel, which can improve particle capture, it can also lead to higher residual moisture in the center of the cake due to increased hydraulic resistance.

The compressibility of your solids plays a major role. Highly compressible solids can form a dense, impermeable layer near the filter cloth, trapping liquid within the rest of the cake.

Impact on Cycle Time

This is the most significant factor. The flow rate of filtrate through the cake decreases dramatically as the cake gets thicker.

Forming the last 10% of a thick cake can take a disproportionately large amount of time compared to the first 90%. This is the principle of diminishing returns in filtration. Pushing for maximum thickness often leads to excessively long and inefficient cycle times.

Impact on Cake Discharge and Handling

The physical properties of the cake dictate how well it releases from the filter cloth.

A cake that is too thin may be "slimy" or sticky, failing to release cleanly and requiring manual intervention. A cake that is too thick can be extremely heavy, putting a strain on both operators and handling equipment.

Key Factors Determining Optimal Thickness

The ideal cake thickness is a function of your slurry, your equipment, and your operational goals.

Slurry Characteristics

The nature of your solids is the most important variable. This includes particle size distribution, shape, and compressibility.

Coarse, crystalline, and incompressible materials (like sand) can form thick, permeable cakes quickly. Fine, slimy, or highly compressible solids (like wastewater treatment sludge) create high resistance and are better suited for thinner cakes and shorter cycles.

Filter Press and Plate Design

The design of your filter press sets the physical limit. The chamber depth of the recessed filter plates dictates the maximum possible cake thickness. A 32 mm chamber will produce a 32 mm cake.

Process Goals

Your primary objective dictates the strategy. If your goal is to process the maximum amount of solids per day (throughput), you will favor thinner cakes and faster cycles. If your goal is to achieve the absolute maximum cake dryness, you may need a longer cycle, but only up to the point of diminishing returns.

Understanding the Trade-offs: Thin vs. Thick Cakes

Choosing your target cake thickness involves a direct trade-off between speed and volume per cycle.

The Case for Thinner Cakes

Thinner cakes are ideal for increasing overall plant throughput. Because the filtration cycle is much shorter, you can process more batches in a given shift.

This approach is particularly effective for slow-filtering or highly compressible slurries where building a thick cake is economically unfeasible due to prohibitive cycle times.

The Case for Thicker Cakes

Thicker cakes mean fewer cycles are needed to process a given volume of slurry. This results in less mechanical wear and tear on the press, filter cloths, and associated pumps.

Furthermore, a thicker, well-formed cake often releases from the cloth more cleanly and consistently, reducing the labor required for discharge.

The Point of Diminishing Returns

For any given slurry, there is a point where increasing the filtration time provides a negligible reduction in cake moisture. Operating past this point wastes energy, time, and capacity. The goal is to find this "sweet spot" where the cake is sufficiently dry and the cycle time is economically viable.

How to Determine the Right Thickness for Your Application

The optimal cake thickness must be determined empirically through testing, as theoretical calculations alone are insufficient.

- If your primary focus is maximum throughput: Start with thinner cakes (e.g., 25-32 mm) to achieve rapid cycle times, especially for difficult-to-dewater materials.

- If your primary focus is maximum cake dryness: Conduct tests to find the point of diminishing returns, where additional press time no longer significantly reduces moisture content.

- If your primary focus is easy cake handling: Target a thickness that is robust enough for a clean, consistent release from the filter cloths without being too heavy for your discharge system.

- If you are starting a new process: Always perform bench-scale or pilot-scale testing to evaluate how cake thickness impacts cycle time and final moisture for your specific slurry.

Ultimately, optimizing your filter press operation means finding the ideal cake thickness that achieves your process goals in the most efficient and cost-effective manner.

Summary Table:

| Aspect | Thin Cake (e.g., 25-32 mm) | Thick Cake (e.g., 40-50 mm) |

|---|---|---|

| Cycle Time | Faster cycles, higher throughput | Slower cycles, fewer cycles per day |

| Moisture Content | May be higher for some slurries | Can be lower, but subject to diminishing returns |

| Cake Handling | Can be sticky or difficult to release | Often releases cleanly, but can be heavy |

| Best For | Maximizing throughput, compressible solids | Maximizing dryness per cycle, robust solids |

Struggling to balance cake thickness, cycle time, and moisture content? KINTEK specializes in lab equipment and consumables for filtration testing and optimization. Our experts can help you determine the ideal cake thickness for your specific slurry, maximizing your dewatering efficiency and overall process profitability. Contact our filtration specialists today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy