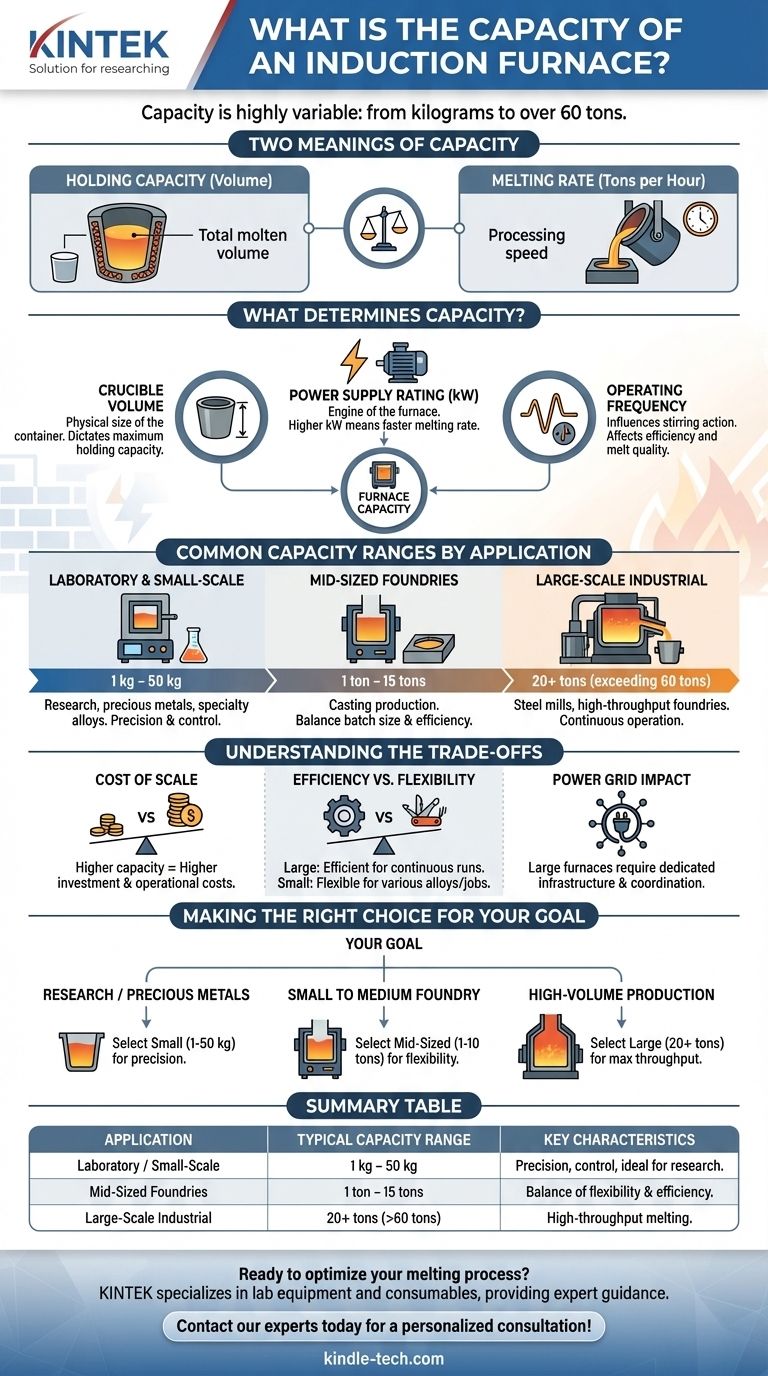

The capacity of an induction furnace is not a single value but a highly variable specification that can range from a few kilograms for specialized laboratory work to over 60 tons for large-scale industrial foundries. The furnace's capacity is fundamentally defined by the volume of its crucible and the power of its supply, which together determine how much metal can be melted and how quickly.

The central concept to understand is that "capacity" has two meanings: the holding capacity (the total volume of molten metal the furnace can contain) and the melting rate (how many tons per hour it can process). The right furnace is always a balance between these two factors, dictated by your specific production needs.

What Determines an Induction Furnace's Capacity?

The nameplate capacity of an induction furnace is a result of several interconnected design choices. Understanding these factors is key to grasping how a furnace is matched to its intended job.

Crucible Volume

The most direct measure of capacity is the physical size of the crucible—the refractory-lined container that holds the metal. This volume dictates the maximum amount of molten metal the furnace can hold at any one time, often referred to as its holding capacity.

Power Supply Rating (kW)

The power supply is the engine of the furnace. A higher kilowatt (kW) rating means more energy can be delivered to the metal charge. This directly translates to a faster melting rate. Two furnaces with the same crucible size but different power ratings will have vastly different levels of productivity.

Operating Frequency

The alternating current's frequency influences the stirring action within the molten metal. Lower frequencies penetrate deeper and create more vigorous stirring, which is ideal for large furnaces melting scrap. Higher frequencies are better for smaller furnaces or applications requiring less turbulence. This choice affects efficiency and melt quality, indirectly influencing the practical capacity.

Common Capacity Ranges by Application

Induction furnaces are not one-size-fits-all. Their capacity is scaled precisely for their environment.

Laboratory and Small-Scale Use

For research, precious metal casting, or specialty alloys, benchtop or small standalone furnaces are common. These units have capacities measured in kilograms, often from 1 kg to 50 kg.

Mid-Sized Iron and Steel Foundries

The most common industrial application is in foundries producing castings. These furnaces typically range from 1 ton to 15 tons. This size offers a good balance between batch size for various casting jobs and the efficiency needed for commercial production.

Large-Scale Industrial Melting

In large steel mills or high-throughput foundries, much larger furnaces are required. These can have capacities exceeding 60 tons. Such installations are designed for continuous or semi-continuous operation and demand a massive, dedicated power infrastructure.

Understanding the Trade-offs

Selecting a furnace capacity involves balancing performance with practical limitations. A larger furnace is not always better.

Cost of Scale

A larger capacity furnace represents a significantly higher capital investment. The costs of the power supply, cooling systems, and physical installation scale up dramatically with size. Ongoing operational costs, especially energy consumption, are also much higher.

Efficiency vs. Flexibility

Large furnaces are most efficient when melting full batches on a continuous schedule. Using a 20-ton furnace to melt a 5-ton batch is highly inefficient. Smaller furnaces offer greater flexibility for foundries that need to pour different alloys or handle smaller, custom jobs.

Power Grid Impact

A key feature of modern induction furnaces is a "soft start" to minimize impact on the local electric grid. However, very large furnaces still represent a substantial electrical load that can require coordination with utility providers and significant investment in substation infrastructure.

Making the Right Choice for Your Goal

The optimal furnace capacity is the one that aligns directly with your operational goals for throughput, alloy type, and batch size.

- If your primary focus is research or precious metals: A small, tabletop furnace with a capacity measured in kilograms (1-50 kg) provides the necessary precision and control.

- If you run a small to medium foundry: A furnace in the 1 to 10-ton range offers the best blend of batch-size flexibility and production efficiency.

- If your primary focus is high-volume steel or iron production: You require large-capacity furnaces (20+ tons) paired with a high-kW power supply to maximize your melting rate.

Ultimately, choosing the right capacity is about matching the furnace's capabilities to your plant's production demand.

Summary Table:

| Application | Typical Capacity Range | Key Characteristics |

|---|---|---|

| Laboratory / Small-Scale | 1 kg - 50 kg | Precision, control, ideal for research & precious metals |

| Mid-Sized Foundries | 1 ton - 15 tons | Balance of batch flexibility and production efficiency |

| Large-Scale Industrial | 20+ tons (exceeding 60 tons) | High-throughput melting for steel/iron production |

Ready to optimize your melting process? The right induction furnace capacity is critical for efficiency and throughput. KINTEK specializes in lab equipment and consumables, providing expert guidance to laboratories and foundries. We'll help you select the perfect furnace to meet your production goals and budget. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys