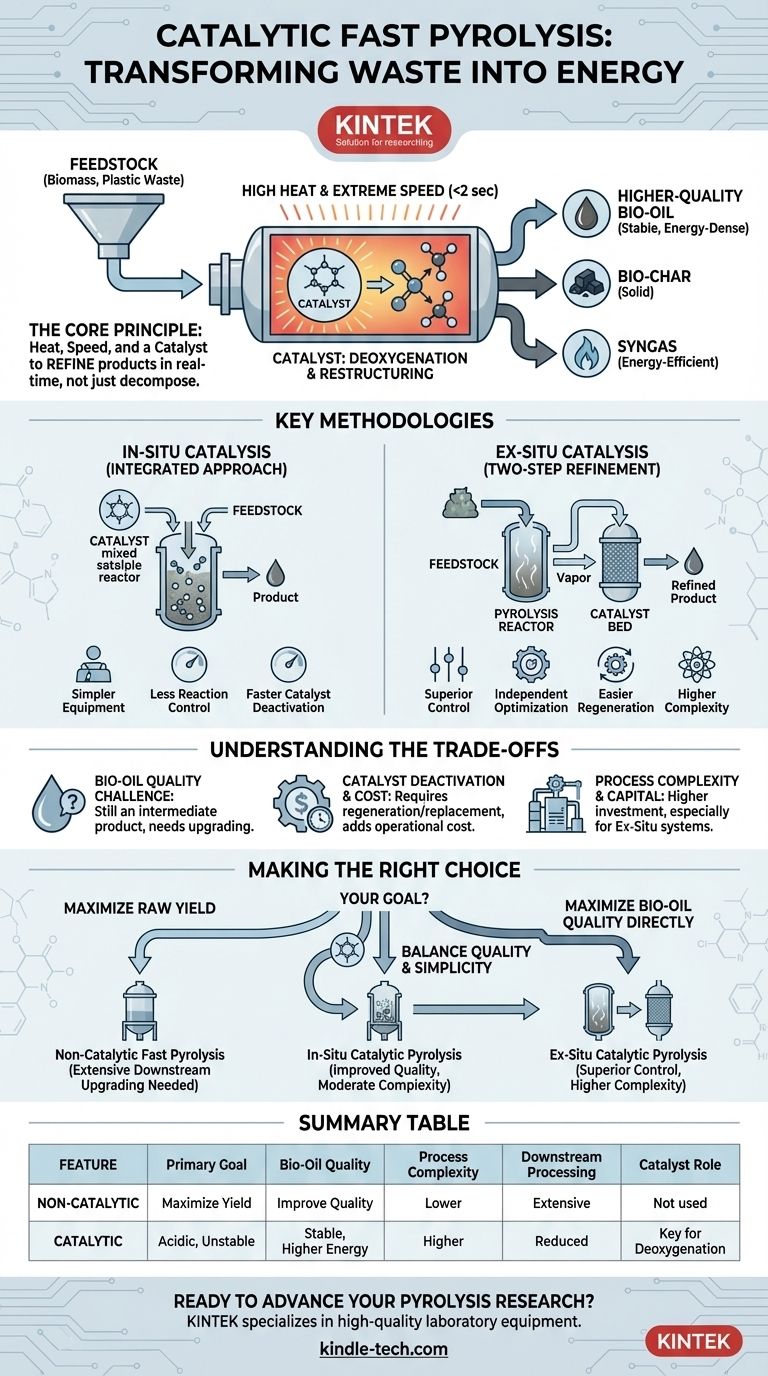

In essence, catalytic fast pyrolysis is a sophisticated thermochemical conversion process that uses high heat, extreme speed, and a chemical catalyst to break down materials like biomass or plastic waste. Unlike standard pyrolysis, the addition of a catalyst actively steers the chemical reactions to produce a higher-quality, more stable liquid fuel known as bio-oil, along with bio-char and syngas.

The core purpose of adding a catalyst to fast pyrolysis is not merely to decompose the material, but to refine the resulting products in real-time. It selectively removes oxygen and restructures molecules to create a more energy-dense and valuable bio-oil, reducing the need for extensive downstream processing.

The Core Principle: Heat, Speed, and a Catalyst

What is Pyrolysis?

At its most basic level, pyrolysis is the thermal decomposition of materials at elevated temperatures in an oxygen-deprived environment.

By heating a feedstock like wood chips or plastic waste to 400-900°C without oxygen, its complex molecules break down into simpler, more valuable products instead of combusting.

Why "Fast" Pyrolysis?

The "fast" in fast pyrolysis refers to the incredibly high heating rate and short residence time (typically less than 2 seconds) for the vapors inside the reactor.

This speed is critical for maximizing the yield of liquid bio-oil. Slower processes tend to produce more solid bio-char and non-condensable gases.

The gases produced, such as methane and hydrogen, are often captured and burned to provide the heat needed to sustain the pyrolysis process, making the system more energy-efficient.

The Decisive Role of the "Catalyst"

The catalyst is the key differentiator. It is a substance introduced into the process to facilitate specific chemical reactions without being consumed itself.

In catalytic pyrolysis, its primary job is deoxygenation—removing oxygen atoms from the pyrolysis vapors. This creates a bio-oil that is more stable, less acidic, and has a higher energy content, making it more similar to conventional crude oil.

Key Methodologies in Catalytic Pyrolysis

There are two primary strategies for incorporating a catalyst into the pyrolysis process, each with its own set of advantages and complexities.

In-Situ Catalysis: The Integrated Approach

In this method, the catalyst is mixed directly with the feedstock (e.g., biomass, shredded plastic) and fed into the pyrolysis reactor together.

This approach is simpler from an equipment standpoint, as it uses a single reactor. However, it offers less control over the reaction conditions and can lead to faster catalyst deactivation.

Ex-Situ Catalysis: The Two-Step Refinement

This more advanced method uses a dual-bed or two-stage system. The feedstock is first pyrolyzed in a non-catalytic reactor, and the resulting hot vapors are then passed over a separate, dedicated bed of catalyst.

Ex-situ catalysis allows for independent optimization of both the pyrolysis and the catalytic upgrading steps, offering superior control over the final product quality. This separation also makes it easier to regenerate the catalyst.

Understanding the Trade-offs

While powerful, catalytic pyrolysis is not a silver bullet. Understanding its limitations is crucial for a realistic assessment of the technology.

The Challenge of Bio-Oil Quality

Even with catalysts, the resulting bio-oil is not a "drop-in" replacement for gasoline or diesel. It is still an intermediate product that often requires further hydrotreating or upgrading to remove remaining impurities and oxygen.

Catalyst Deactivation and Cost

Catalysts inevitably lose their effectiveness over time as their surfaces become coated with carbon ("coke") or contaminated.

The need for periodic regeneration or replacement adds significant operational complexity and cost to the overall process, impacting its economic viability.

Process Complexity and Capital Investment

Adding a catalytic stage, particularly an ex-situ system, increases the capital cost and technical complexity of a pyrolysis plant compared to simpler, non-catalytic designs.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on your end objective, balancing product quality against operational complexity and cost.

- If your primary focus is maximizing raw liquid fuel yield: Non-catalytic fast pyrolysis is the simplest route, but be prepared for extensive and costly downstream upgrading of the acidic, unstable bio-oil.

- If your primary focus is producing higher-quality, more stable bio-oil directly: Catalytic pyrolysis is the superior choice, with ex-situ methods offering the most precise control over the final product chemistry.

- If your primary focus is a balance of improved quality and operational simplicity: In-situ catalytic pyrolysis offers a compromise, improving oil quality without the full complexity of a two-stage reactor system.

Ultimately, catalytic fast pyrolysis represents a critical engineering step toward efficiently converting low-value waste streams into high-value, refined energy products.

Summary Table:

| Feature | Non-Catalytic Fast Pyrolysis | Catalytic Fast Pyrolysis |

|---|---|---|

| Primary Goal | Maximize raw liquid yield | Improve bio-oil quality & stability |

| Bio-Oil Quality | Acidic, unstable, lower energy | More stable, less acidic, higher energy |

| Process Complexity | Lower | Higher (especially ex-situ) |

| Downstream Processing | Extensive upgrading needed | Reduced upgrading required |

| Catalyst Role | Not used | Key for deoxygenation & molecule restructuring |

Ready to advance your pyrolysis research or scale-up? KINTEK specializes in providing high-quality laboratory equipment and consumables for thermochemical conversion processes like catalytic fast pyrolysis. Whether you need robust reactors, temperature control systems, or catalyst testing supplies, our solutions are designed to enhance your lab's efficiency and accuracy. Contact our experts today to discuss how we can support your specific project needs and help you achieve superior results.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What process is used to extract essential oils? From Crude Plant to Pure Perfume

- What is sintered material? A Guide to High-Performance Powder Metallurgy

- What are the disadvantages of metal iron? Key Limitations and Why We Use Alloys Instead

- How is thermal data used in furnaces for radioactive waste immobilization? Master Precise Thermal Control

- What is the most efficient heat transfer system? Optimize Performance for Your Application

- What are the safety precautions when using a test tube? Essential Lab Safety Guidelines

- How do you check a diamond CVD? Verify Your Lab-Grown Diamond with Confidence

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding