At its most fundamental level, the core component of a peristaltic pump is the flexible, elastomeric tubing or hose. While several parts are required for operation, the tubing is the defining element because it is the only part that comes into contact with the fluid. This single design choice is responsible for the pump's signature benefits, such as contamination-free operation and the ability to handle a wide variety of liquids.

While a peristaltic pump is a system of interconnected parts, the flexible tubing is the central component that dictates fluid compatibility, ensures purity, and ultimately defines the pump's performance and limitations.

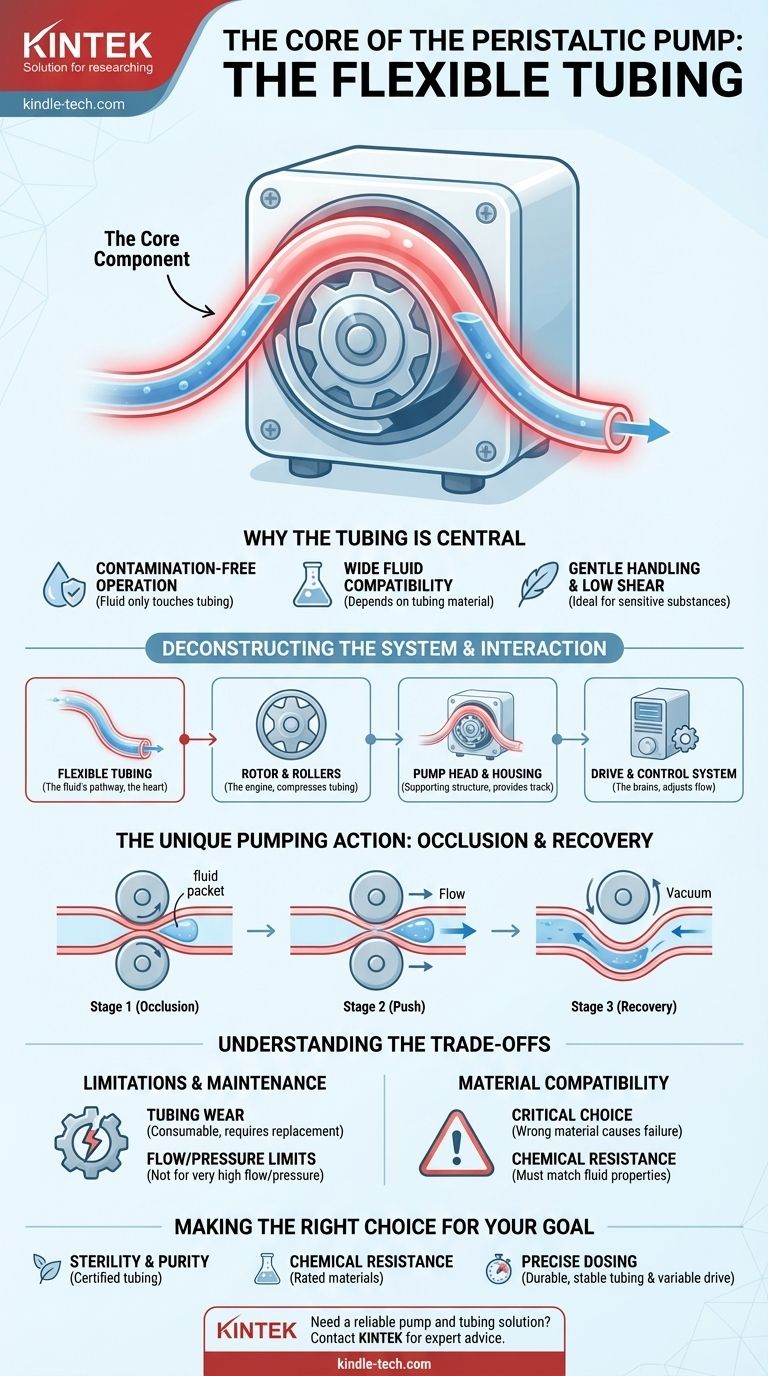

Deconstructing the Peristaltic Pump System

To fully grasp why the tubing is so central, it's helpful to understand how it interacts with the other key components. The pump operates as a complete system, where each part has a distinct role in creating the peristaltic action.

The Flexible Tubing: The Heart of the Pump

The tubing is the fluid's pathway. It is selected based on its ability to withstand repeated compression, its chemical compatibility with the fluid being pumped, and its durability. Common materials include silicone, PVC, and various thermoplastic elastomers, each offering different properties for specific applications.

The Rotor and Rollers: The Engine of Peristaltic Action

The rotor is the rotating part within the pump head, driven by a motor. Mounted on the rotor are several rollers or, in some high-pressure designs, shoes. As the rotor turns, these rollers press against the flexible tubing, compressing it.

The Pump Head and Housing: The Supporting Structure

The pump head houses the rotor and rollers and provides a rigid, curved track against which the tubing is compressed. This entire assembly is protected by the pump's outer housing. The precise geometry of the pump head ensures consistent and effective occlusion (squeezing) of the tube.

The Drive and Control System: The Brains of the Operation

The drive motor provides the power to turn the rotor. In modern pumps, this is often a variable-speed motor connected to a control system. This allows the operator to precisely adjust the rotor's speed and direction, which directly controls the fluid's flow rate and allows for bi-directional pumping.

How These Components Create a Unique Pumping Action

The brilliance of the peristaltic pump lies in the elegant simplicity of its mechanism. The components work in concert to mimic the biological process of peristalsis, similar to how an esophagus moves food.

The Principle of Occlusion and Recovery

As a roller moves along the tubing, it pinches it closed, a process called occlusion. This action traps a "pillow" or "packet" of fluid between two roller points. As the roller continues to rotate, it pushes this packet of fluid forward. Behind the roller, the tubing springs back to its original shape, creating a vacuum that draws more fluid into the tube.

Achieving Contamination-Free Flow

Because the fluid is always fully contained within the tubing, it never touches any of the pump's mechanical parts. This is the pump's single greatest advantage. It prevents contamination of the fluid and protects the pump's components from corrosive or abrasive liquids.

Gentle Handling and Low Shear

The gentle squeezing action exerts very low shear force on the fluid. This makes peristaltic pumps ideal for handling sensitive substances that can be damaged by other pump types, such as live cells, fragile proteins, or shear-sensitive polymers.

Understanding the Trade-offs

The tubing's central role also makes it the primary source of the pump's limitations and maintenance requirements. Understanding these trade-offs is critical for effective operation.

Tubing Wear and Replacement

The constant compression and relaxation cycle causes the tubing to wear out over time. It is a consumable component that must be replaced periodically to ensure consistent performance and prevent failure. This is the most common maintenance task for a peristaltic pump.

Material Compatibility is Non-Negotiable

Choosing the wrong tubing material for your specific fluid is the most common cause of pump failure. An incompatible chemical can cause the tubing to swell, harden, or degrade, leading to a loss of pumping efficiency and potential rupture.

Flow Rate and Pressure Limitations

The flow rate is determined by the inner diameter of the tubing and the speed of the rotor. While excellent for precise, low-flow applications, peristaltic pumps are generally not suited for the very high flow rates or pressures achievable with other pump designs.

Making the Right Choice for Your Goal

Your application's primary goal should guide your component selection, starting with the tubing.

- If your primary focus is sterility and purity: Prioritize tubing materials certified for your application (e.g., USP Class VI for biopharma) that will not leach chemicals into your fluid.

- If your primary focus is chemical resistance: Select a tubing material specifically rated to handle the aggressive or corrosive chemicals you are pumping to ensure system longevity and safety.

- If your primary focus is precise dosing and metering: Choose a durable, dimensionally stable tubing paired with a high-quality variable-speed drive to achieve consistent and repeatable flow rates over the life of the tube.

Understanding that the flexible tube is the true heart of the pump empowers you to select, operate, and maintain this technology effectively.

Summary Table:

| Component | Role in the System | Key Consideration |

|---|---|---|

| Flexible Tubing | The core component; the only part touching the fluid. | Material compatibility, durability, and chemical resistance. |

| Rotor & Rollers | Compress the tubing to create the peristaltic action. | Number of rollers affects pulse rate and tube life. |

| Pump Head | Houses the rotor and provides the track for compression. | Geometry ensures consistent occlusion of the tube. |

| Drive & Control System | Powers the rotor and allows for speed/direction control. | Enables precise flow rate adjustment and metering. |

Need a reliable peristaltic pump for your sensitive or corrosive fluids?

At KINTEK, we specialize in laboratory equipment, including peristaltic pumps and the vital consumable tubing that powers them. We understand that the right tubing is critical for achieving contamination-free, precise, and gentle fluid transfer in applications from biopharma to chemical processing.

Our experts can help you select the ideal pump and tubing combination based on your specific fluid compatibility, sterility, and dosing requirements. Ensure the integrity of your samples and the longevity of your equipment.

Contact our technical team today for a personalized consultation and discover the KINTEK difference in lab fluid handling.

Visual Guide

Related Products

- Electrode Fixture for Electrochemical Experiments

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Assemble Square Lab Press Mold for Laboratory Applications

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

People Also Ask

- What are the steps in additive manufacturing process? A Complete Guide to the Digital-to-Physical Workflow

- What is plasma magnetron sputtering? A Guide to High-Performance Thin-Film Deposition

- Does pyrolysis change chemical composition? Yes, it fundamentally transforms materials through thermal decomposition

- What is the best solvent for FTIR? Master Solvent Selection for Clear, Accurate Spectra

- What is the difference between short path and thin film? Choosing the Right Distillation Method for Your Lab

- What is the basic instrument for IR spectrometry? FT-IR Spectrometers for Modern Chemical Analysis

- What is a natural sintering? Uncover the Geological Process That Forms Ore Deposits

- Are lab grown diamonds used for industry? The Unmatched Choice for Precision and Performance