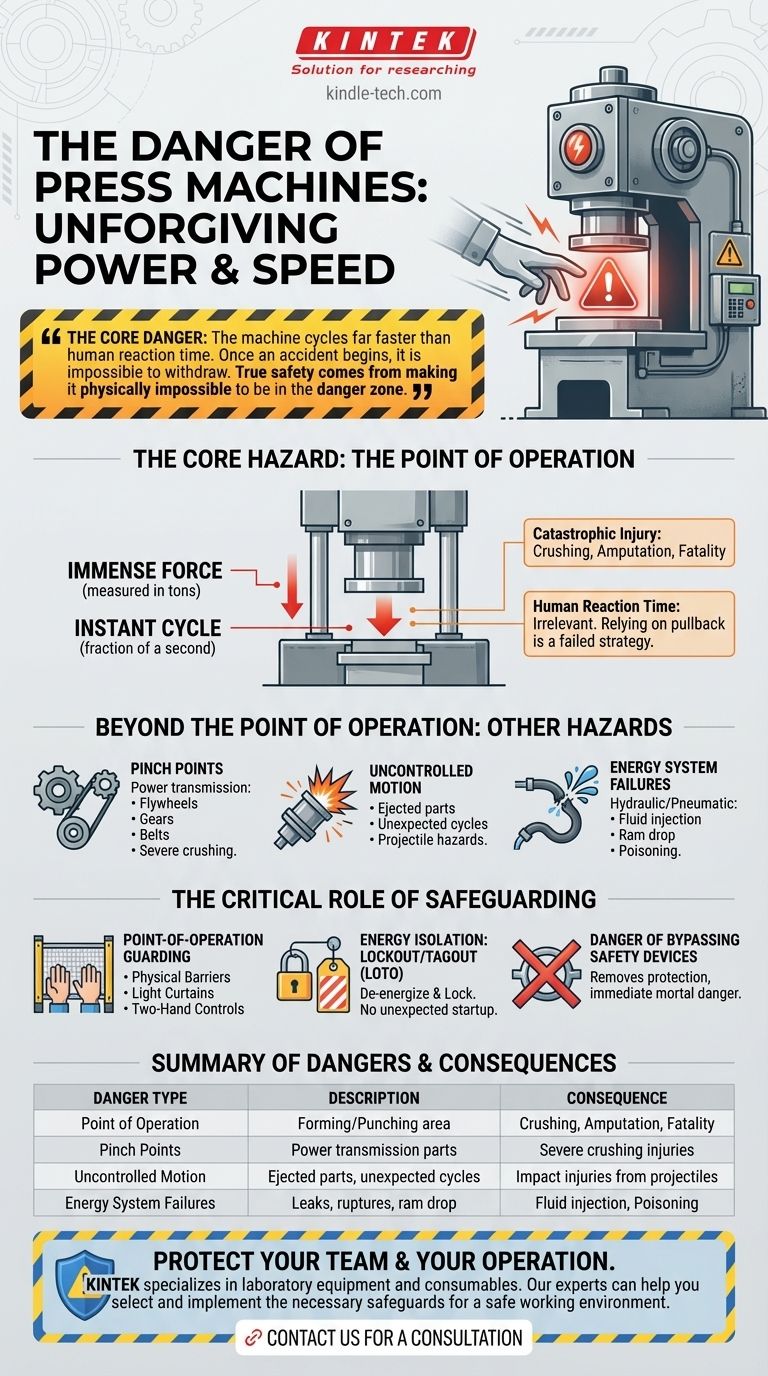

The fundamental danger of a press machine is its unforgiving power and speed, which creates an extreme risk of crushing, amputation, or fatality at the point of operation. The machine cycles far faster than human reaction time, meaning once an accident begins, it is impossible for an operator to withdraw in time.

The core danger of a press machine is not merely its mechanical force, but the deceptive zone where human interaction meets the machine's work cycle. True safety comes from understanding that operators cannot be expected to be "fast enough" and requires engineering controls that make it physically impossible to be in the danger zone during operation.

The Core Hazard: The Point of Operation

The most severe and frequent injuries occur at the "point of operation." This is the area of the press where the work of forming, punching, or assembling material is actually performed.

The Mechanics of Catastrophic Injury

A press exerts immense force—measured in tons—within a fraction of asecond. Any body part caught between the die set (the ram and the bed) will be subjected to this force, resulting in immediate and severe crushing or amputation.

There is no "minor" injury at the point of operation. The machine is designed to shear and form metal, and it does not distinguish between the workpiece and a human hand or arm.

Why Human Reaction Time is Irrelevant

A typical mechanical press can complete a full stroke in a fraction of a second. Human reaction time, from perceiving a threat to initiating muscle movement, is significantly slower.

Relying on an operator's ability to pull back their hands is a failed safety strategy. It is not a matter of skill or attention; it is a matter of biomechanics.

Beyond the Point of Operation: Other Hazards

While the point of operation is the primary concern, the entire machine presents numerous dangers that must be managed.

Pinch Points in Power Transmission

The components that transfer power from the motor to the ram—such as flywheels, gears, belts, and crankshafts—create dangerous pinch and shear points. Proper guarding must be in place to prevent contact with these moving parts.

Uncontrolled Motion and Ejected Parts

Mechanical failure can lead to the ejection of broken die components or scrap material at high velocity, creating a projectile hazard. Similarly, unexpected or unintended machine cycles can occur due to a failure in the clutch or control system.

Energy System Failures

Hydraulic and pneumatic presses present unique risks. A ruptured high-pressure hose can inject hydraulic fluid into the skin, causing severe tissue damage and poisoning. Leaking valves can lead to a gradual drift or sudden drop of the press ram.

The Critical Role of Safeguarding

The only reliable way to prevent press-related injuries is through robust safeguarding methods that create a barrier between the operator and the hazard.

Point-of-Operation Guarding

This is the most critical layer of protection. Methods include:

- Physical Barriers: Fixed guards that prevent any part of an operator's body from reaching the danger zone.

- Presence-Sensing Devices: Light curtains or laser scanners that stop the press stroke if the optical field is broken.

- Two-Hand Controls: Requires the operator to use both hands to actuate the machine, ensuring their hands are away from the die area during the stroke.

Energy Isolation: Lockout/Tagout (LOTO)

During maintenance, setup, or die changes, the press must be completely de-energized. Lockout/Tagout is a formal procedure where all power sources (electrical, hydraulic, pneumatic) are turned off and locked, preventing any possibility of an unexpected startup. Turning off a switch is not enough; the energy source must be physically locked.

The Danger of Bypassing Safety Devices

A common cause of incidents is the intentional bypassing of safety devices, often by operators or setup personnel attempting to speed up production. This action removes all engineered protections and puts the operator in immediate, mortal danger.

Making the Right Choice for Your Goal

Safety is not a single action but a continuous process of risk assessment and control. Your approach must be multi-layered and consistently enforced.

- If your primary focus is operator protection: Implement non-bypassable point-of-operation guarding, such as interlocked physical barriers or presence-sensing devices, as your first and most important line of defense.

- If your primary focus is maintenance safety: Enforce a strict and audited Lockout/Tagout (LOTO) program for anyone performing service, ensuring they are trained to isolate all forms of energy.

- If your primary focus is systemic safety culture: Invest in comprehensive training that goes beyond simple operation, teaching every employee why the safety systems exist and the catastrophic consequences of defeating them.

A safe press operation is one where it is physically impossible for an accident to occur, regardless of operator attention or intent.

Summary Table:

| Danger Type | Description | Consequence |

|---|---|---|

| Point of Operation | Area where material is formed or punched. | Crushing, amputation, fatality. |

| Pinch Points | Gears, belts, and flywheels in power transmission. | Severe crushing injuries. |

| Uncontrolled Motion | Ejected parts or unexpected machine cycles. | Impact injuries from projectiles. |

| Energy System Failures | Hydraulic/pneumatic leaks or ruptures. | Fluid injection, poisoning, ram drop. |

Protect your team and your operation. The dangers of a press machine are severe, but they are manageable with the right equipment, training, and safety culture. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select and implement the necessary safeguards to create a safe working environment. Don't compromise on safety—contact us today for a consultation and ensure your press operations are protected by the highest standards.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy