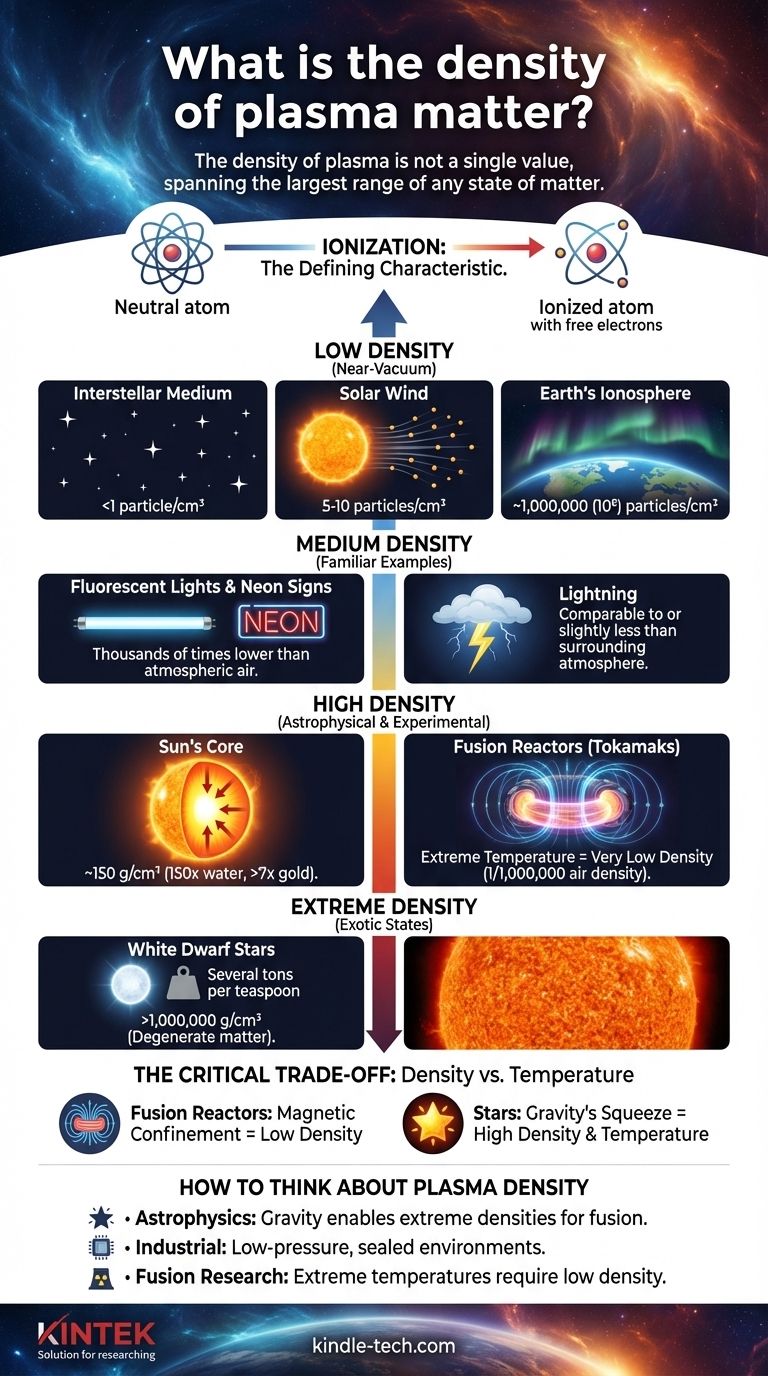

The density of plasma is not a single value but spans the largest range of any state of matter. Plasma density can be far lower than the most diffuse gas or significantly higher than the densest solid metal. For example, the plasma in interstellar space may have fewer than one particle per cubic centimeter, while the plasma in a star's core can reach densities over 150 times that of water.

The defining characteristic of plasma is not its density but its state of ionization—the presence of free-moving charged particles (ions and electrons). Because you can ionize a substance at almost any density, from a near-vacuum to a super-compressed solid, plasma does not have a fixed or typical density.

What Defines Plasma? (Hint: It's Not Density)

To understand plasma's properties, we must shift our focus from density to the process of its creation and its electrical nature.

From Gas to Plasma: The Role of Energy

Plasma is most commonly formed by adding immense energy, usually in the form of heat, to a gas. This energy becomes so great that it overcomes the force holding electrons to their atomic nuclei.

When electrons are stripped away, the previously neutral atoms become positively charged ions. The result is a chaotic, superheated soup of free electrons and ions. This electrically charged state is what defines plasma.

The Key Metric: Degree of Ionization

A material's "plasm-ness" is measured by its degree of ionization, which is the percentage of atoms that have been stripped of one or more electrons.

A weakly ionized plasma, like in a fluorescent light bulb, may only have 1% of its atoms ionized, with the rest remaining neutral gas. A fully ionized plasma, like in the sun's core, has virtually no neutral atoms remaining.

Why Density is a Secondary Characteristic

Density is simply a measure of mass per unit volume. In plasma, this means counting the mass of all ions, electrons, and any remaining neutral atoms in a given space.

Because you can create a plasma from a very thin, low-density gas or a very compressed, high-density material, the resulting plasma's density is a reflection of its starting conditions, not a fundamental property of the plasma state itself.

A Tour Through the Universe of Plasma Densities

The sheer range of plasma densities is best understood through examples, from the near-emptiness of space to the crushing pressure inside a star.

Low-Density Plasmas (Near-Vacuum Conditions)

- Interstellar Medium: The "empty" space between stars is a hyper-diffuse plasma with a density of less than 1 particle per cubic centimeter.

- Solar Wind: The stream of particles flowing from the Sun has a density of around 5-10 particles per cubic centimeter.

- Earth's Ionosphere: This upper atmospheric layer, responsible for the aurora, has a peak density of about 1 million (10⁶) particles per cubic centimeter. This is still vastly less dense than the air we breathe.

Medium-Density Plasmas (Familiar Examples)

- Fluorescent Lights & Neon Signs: The plasma in these tubes is created from a low-pressure gas, resulting in a density thousands of times lower than atmospheric air.

- Lightning: A lightning bolt is a transient channel of hot, ionized air. While locally very energetic, its overall density is comparable to or slightly less than the surrounding atmosphere because of its extreme thermal expansion.

High-Density Plasmas (Astrophysical & Experimental)

- The Sun's Core: Under immense gravitational pressure, the plasma at the center of the Sun reaches a density of around 150 g/cm³, which is about 150 times the density of water and over 7 times the density of solid gold.

- Fusion Reactors (Tokamaks): The plasma in an experimental fusion reactor is incredibly hot (over 150 million °C) but is intentionally kept at a very low density—about one-millionth the density of air.

Extreme-Density Plasmas (Exotic States)

- White Dwarf Stars: The core of a dead star is an exotic form of plasma called degenerate matter. Here, atomic structures have completely collapsed, reaching densities of 1 million g/cm³ or more. A single teaspoon of this material would weigh several tons.

The Critical Trade-off: Density vs. Temperature

A common source of confusion is the relationship between temperature and density. In our daily experience, heating a gas makes it expand and become less dense. In plasma physics, the relationship is more complex and depends on the environment.

The Fusion Reactor Problem

In a tokamak fusion device, the goal is to achieve temperatures even hotter than the sun's core to force atomic nuclei to fuse. However, the pressure exerted by a plasma is a product of its density and its temperature.

At 150 million degrees, even a tiny amount of density would create an outward pressure far too powerful for any magnetic field to contain. Therefore, these reactors must use an extremely low-density plasma to keep the total pressure manageable.

The Stellar Solution: Gravity's Squeeze

Stars solve the pressure problem with their own immense gravity. Gravity provides a near-unbreakable confinement force, allowing the star's core to sustain both unimaginably high temperatures and extremely high densities simultaneously. This unique combination is what makes stellar fusion possible.

How to Think About Plasma Density

To accurately assess a plasma's characteristics, you must consider its context. Always ask where and how the plasma exists.

- If your primary focus is astrophysics: Remember that gravity is the key enabler, allowing stars to achieve the extreme densities required for nuclear fusion in their cores.

- If your primary focus is industrial applications (like etching or lighting): Know that these are almost always low-pressure, low-density plasmas created and controlled within a sealed environment.

- If your primary focus is fusion energy research: Understand the critical trade-off where achieving extreme temperatures necessitates maintaining very low densities for magnetic confinement to work.

Ultimately, you should define plasma by its electrical charge and energy level, not by how much of it is packed into a given space.

Summary Table:

| Plasma Type | Example | Approximate Density |

|---|---|---|

| Low-Density | Interstellar Medium | <1 particle/cm³ |

| Medium-Density | Fluorescent Light | Lower than air |

| High-Density | Sun's Core | ~150 g/cm³ |

| Extreme-Density | White Dwarf Star | >1,000,000 g/cm³ |

Unlock the potential of plasma in your lab. Whether you're developing new materials, conducting surface treatments, or pushing the boundaries of research, precise control over plasma processes is critical. KINTEK specializes in advanced lab equipment and consumables for plasma applications, helping laboratories achieve reliable and repeatable results. Contact our experts today to discuss how our solutions can power your next breakthrough.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Why are stainless steel containers used for lithium melt modification? Ensure Purity and Corrosion Resistance

- How does heat treatment affect material? Transform Properties for Superior Performance

- What are the driving forces of sintering? Understanding the Thermodynamics for Better Materials

- What is the voltage of the e-beam evaporator? Understanding the 4-10 kV Range for Optimal Deposition

- What is the history of magnetron sputtering? The 1974 Breakthrough That Revolutionized Thin-Film Coating

- Is biomass a renewable energy source? The truth about sustainable energy

- How are the shelves inside an Ultra Freezer designed to maintain temperature uniformity? Ensuring Sample Integrity with Compartmentalized Shelves

- Why pyrolysis is better than incineration? Transforming Waste into Valuable Resources