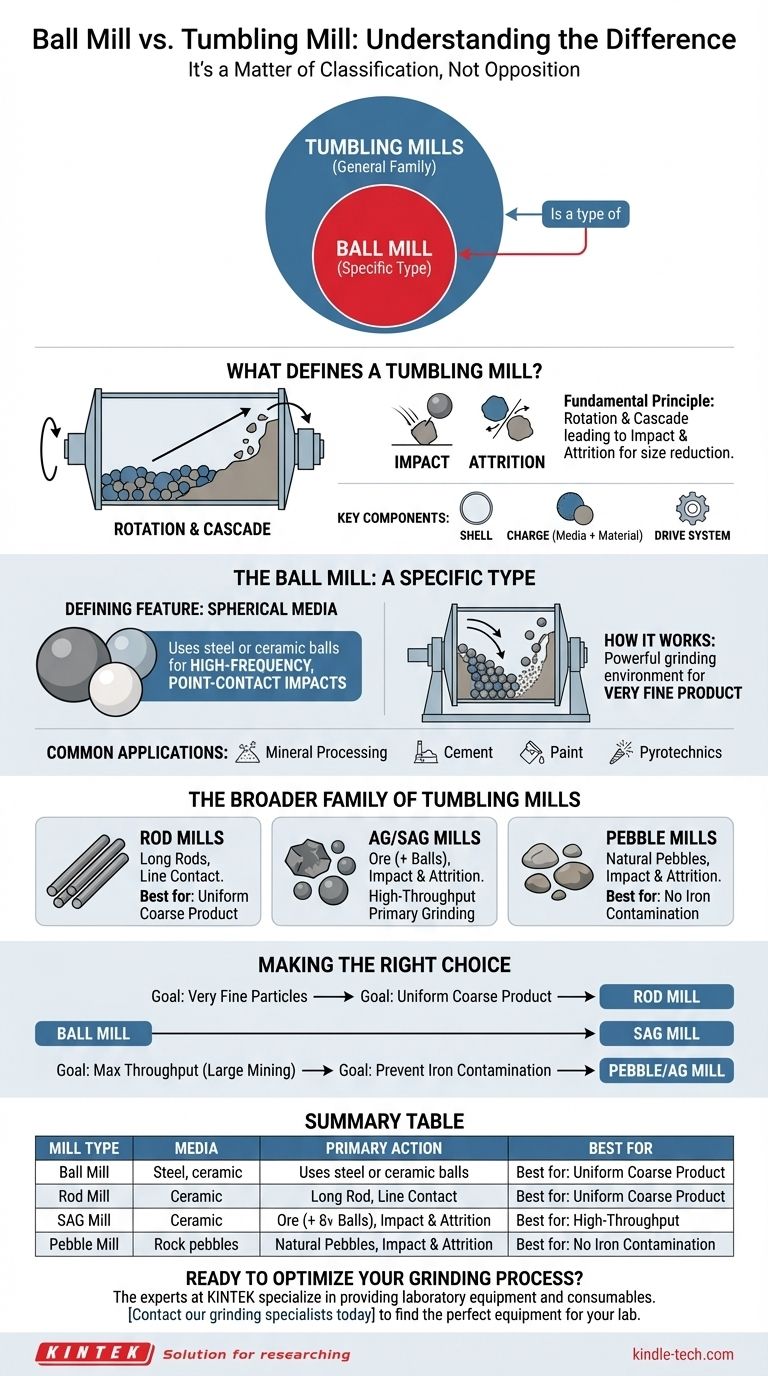

The fundamental difference is not one of opposition, but of classification. A ball mill is a specific type of tumbling mill. The term "tumbling mill" refers to the broad category of grinding equipment that works by rotating a drum, while a "ball mill" is a member of that category defined by its use of spherical grinding media.

The core distinction is simple: "Tumbling Mill" is the general family of machines that tumble material in a rotating drum to grind it. A "Ball Mill" is a specific member of that family that uses steel or ceramic balls as the grinding medium.

What Defines a Tumbling Mill?

A tumbling mill is any grinding machine that reduces particle size by rotating a partially filled horizontal cylinder or shell. The internal collision and friction of the contents cause the material to break down.

The Fundamental Principle: Rotation and Cascade

As the drum rotates, the material and grinding media inside are lifted up the side of the shell. At a certain point, they break away and tumble back down to the bottom of the mill. This continuous process, known as cascading and cataracting, creates the grinding action.

The Grinding Action: Impact and Attrition

Particle size reduction in a tumbling mill occurs through two primary mechanisms:

- Impact: Grinding media falling from the top of the drum strikes the material below, fracturing it.

- Attrition: As the charge slides and tumbles, particles rub against each other and the media, grinding them down.

Key Components of Any Tumbling Mill

All tumbling mills share a basic design: a hollow cylindrical shell lined with wear-resistant materials, a drive system to rotate it, and a charge consisting of the grinding media and the material to be ground.

The Ball Mill: A Specific Type of Tumbling Mill

The ball mill is the most common type of tumbling mill. Its defining characteristic is its grinding media.

The Defining Feature: Spherical Media

A ball mill is named for its use of spherical grinding media, typically made of high-chromium steel, forged steel, or ceramic. These balls create high-frequency, point-contact impacts, which are extremely effective for producing a very fine product.

How It Works in Practice

The small, hard balls cascade and cataract inside the rotating drum, creating a powerful grinding environment. The efficiency of a ball mill is determined by factors like mill speed, ball size, ball charge volume, and material feed rate.

Common Applications

Due to their ability to achieve a very fine grind, ball mills are workhorses in industries such as mineral processing, cement manufacturing, paint production, and pyrotechnics.

Understanding the Broader Family of Tumbling Mills

To fully grasp the context, it's useful to know the other common types of tumbling mills, each distinguished by its media.

Rod Mills

Instead of balls, rod mills use long steel rods as the grinding media. The rods create line contact rather than point contact, which preferentially grinds larger particles and reduces the production of extreme fines (slimes). This makes them ideal for preparing feed for a subsequent ball mill circuit.

Autogenous (AG) and Semi-Autogenous (SAG) Mills

These are very large-diameter mills used in primary grinding circuits.

- AG Mills use large chunks of the ore itself as the grinding media, eliminating the need for steel.

- SAG Mills operate similarly but add a small charge of large-diameter steel balls (typically 5-15% of the volume) to assist in breaking down critical-size ore particles.

Pebble Mills

A pebble mill is functionally identical to a ball mill but uses natural rock pebbles or ceramic media instead of steel balls. This is critical in applications where iron contamination from steel media must be avoided, such as grinding silica for glass or processing certain pigments.

Making the Right Choice for Your Goal

Selecting the correct mill type is a critical decision based on feed material characteristics and the desired product specifications.

- If your primary focus is producing very fine particles: A ball mill is the standard choice due to the high-impact, fine-grinding action of its spherical media.

- If your primary focus is creating a uniform coarse product without over-grinding: A rod mill is often superior because its line-contact grinding targets larger particles more effectively.

- If your primary focus is maximizing throughput in a large-scale mining operation: A SAG mill is the industry workhorse, valued for its ability to process large feed sizes directly from a primary crusher.

- If your primary focus is preventing iron contamination: A pebble mill or an autogenous mill is the correct solution, as they do not use steel grinding media.

Understanding this hierarchy of milling equipment is the first step toward selecting the most efficient and cost-effective grinding solution for your specific goal.

Summary Table:

| Mill Type | Grinding Media | Primary Grinding Action | Best For |

|---|---|---|---|

| Ball Mill | Spherical balls (steel/ceramic) | High-impact, point contact | Producing a very fine grind |

| Rod Mill | Long steel rods | Line contact, selective grinding | Creating a uniform coarse product |

| SAG Mill | Ore + large steel balls | Impact & attrition on large feed | High-throughput primary grinding |

| Pebble Mill | Rock pebbles or ceramic | Impact & attrition (like a ball mill) | Applications requiring no iron contamination |

Ready to Optimize Your Grinding Process?

Choosing the right mill is critical for achieving your target particle size and maximizing operational efficiency. The experts at KINTEK specialize in providing laboratory equipment and consumables, including the right grinding solutions for your specific needs. We help you select the ideal mill—whether it's a ball mill for fine grinding or another type of tumbling mill—to ensure your process is both effective and cost-efficient.

Contact our grinding specialists today to discuss your application and find the perfect equipment for your lab.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the key role of a planetary ball mill for IZO targets? Achieve Atomic-Level Uniformity in Material Preparation

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes