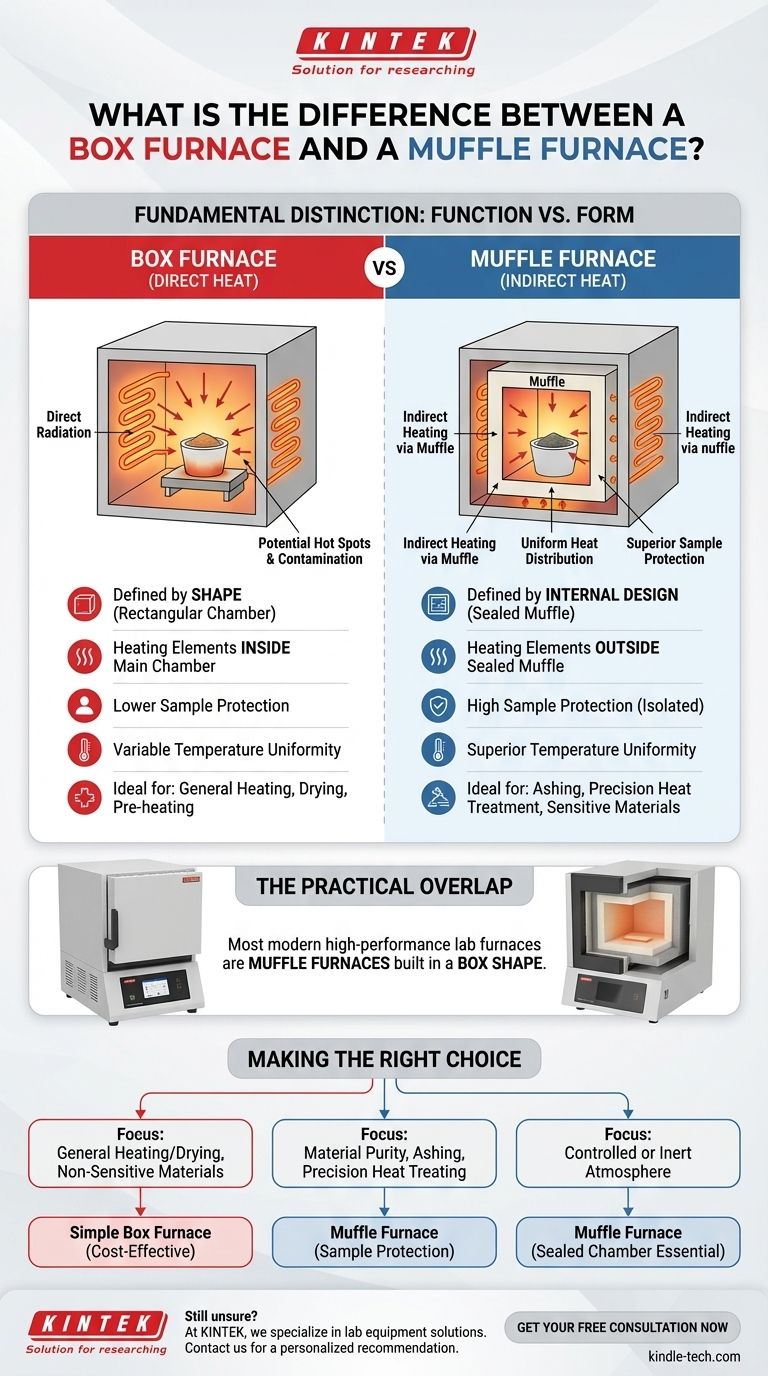

The fundamental difference between a box furnace and a muffle furnace is not their shape, but their method of heating. A "box furnace" refers to the common rectangular shape of the equipment, while a "muffle furnace" specifically describes a furnace with an internal chamber (a muffle) that isolates the material being heated from the direct radiation and contaminants of the heating elements. In practice, most modern laboratory muffle furnaces are built in a box configuration.

The core distinction is function versus form. "Box furnace" describes the external shape, while "muffle furnace" describes an internal design for indirect heating. The terms are not mutually exclusive; you are often looking at a muffle furnace that is housed within a box-style body.

What Defines a Box Furnace?

A box furnace, also known as a chamber furnace, is defined primarily by its physical structure. It is one of the most common types of batch processing furnaces used in labs and industrial settings.

The Defining Characteristic: Shape and Access

The name says it all. A box furnace has a rectangular or cubic chamber. Materials are typically loaded through a single door on the front, much like a conventional oven.

The Heating Method: Often Direct

In its simplest form, a box furnace may have heating elements, such as coiled wires, exposed directly inside the main chamber. The material placed inside is heated by direct radiation from these elements.

Common Applications

A simple, direct-heat box furnace is suitable for general-purpose applications where atmospheric purity and absolute temperature uniformity are not the primary concerns. This includes processes like drying, pre-heating, and certain annealing tasks.

What Defines a Muffle Furnace?

The defining feature of a muffle furnace is its internal construction, which provides a critical advantage for sensitive processes.

The Defining Characteristic: The Inner Muffle

A muffle furnace contains a separate, sealed inner chamber—the muffle—typically made from a high-temperature ceramic or metallic alloy. The heating elements are positioned outside of this muffle.

The Principle of Indirect Heating

The heating elements heat the muffle chamber, and the muffle then radiates heat evenly and uniformly onto the sample inside it. The sample is never directly exposed to the heating elements.

The Primary Benefit: Sample Protection

This indirect heating method is crucial for two reasons. It protects the sample from contamination from combustion byproducts (in gas-fired models) or element degradation. It also provides superior temperature uniformity, as the entire muffle radiates heat from all sides.

Understanding the Trade-offs: Direct vs. Indirect Heat

The choice between a simple box furnace and a muffle furnace boils down to whether your process can tolerate direct exposure to the heating source.

The Simple Box Furnace (Direct Heating)

A basic box furnace without a muffle is mechanically simpler and often less expensive. However, direct radiation can create hot spots, and any particles shed by the heating elements can contaminate the sample.

The Muffle Furnace (Indirect Heating)

A muffle furnace provides a clean, uniform, and controlled heating environment. This is essential for applications like ashing, chemical analysis, and heat-treating sensitive alloys where purity and precision are non-negotiable.

The Practical Overlap

Most high-performance laboratory furnaces on the market today are muffle furnaces built in a box shape. When professionals refer to a "lab furnace," they are almost always picturing a box-style muffle furnace. The term "box furnace" is often used to describe the general form factor.

Making the Right Choice for Your Application

To select the correct equipment, focus on the needs of your material and process, not just the name.

- If your primary focus is general heating or drying non-sensitive materials: A simple, direct-heat box furnace is often a sufficient and cost-effective solution.

- If your primary focus is material purity, ashing, or high-precision heat treating: You require a muffle furnace to protect the sample and ensure superior temperature uniformity.

- If your primary focus is working with a controlled or inert atmosphere: A muffle furnace is essential, as the sealed inner chamber is necessary to maintain the desired atmosphere.

Ultimately, choosing the right furnace depends on a single question: does your sample need to be protected from the heating source?

Summary Table:

| Feature | Box Furnace (Direct Heat) | Muffle Furnace (Indirect Heat) |

|---|---|---|

| Primary Definition | Defined by its rectangular, box-like shape | Defined by its sealed inner chamber (muffle) |

| Heating Method | Heating elements are often inside the main chamber | Heating elements are outside the sealed muffle |

| Sample Protection | Lower; sample exposed to heating elements | High; sample is isolated for purity |

| Temperature Uniformity | Can have hot spots | Superior, uniform heating from all sides |

| Ideal For | General heating, drying, pre-heating | Ashing, precise heat treatment, sensitive materials |

Still unsure which furnace is right for your laboratory's specific needs?

At KINTEK, we specialize in providing the perfect lab equipment solutions. Our experts can help you determine whether a standard box furnace or a high-precision muffle furnace is the best fit for your processes, ensuring optimal results for material purity, ashing, or heat treatment.

Contact us today to discuss your application requirements and get a personalized recommendation. Let KINTEK be your trusted partner in laboratory excellence.

Get Your Free Consultation Now

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does a high-temperature calcination furnace play in converting composite fibers? Achieve Pure TiO2 & ZnO.

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- What function do high-temperature muffle or tube furnaces with inert atmosphere protection serve in alumina coating?

- What is the function of a muffle furnace in Nb-O coated NMC powder preparation? Optimize Your Material Purity

- Why is a high-temperature box furnace used for GX40CrNiSi25-20 homogenization? Optimize Your Material Baseline

- How does a high-temperature muffle furnace influence Zirconia thin films? Master Crystal Structure Evolution

- How are muffle or atmosphere furnaces used in Y-Ti-Zr-O synthesis? Optimize Your ODS Steel Precursors

- What is the difference between a muffle furnace and a box furnace? A Guide to Choosing the Right Lab Furnace