At its core, the distinction is one of category versus type. An "electric furnace" is a broad term for any furnace that uses electricity for heat, while an "electric arc furnace" is a specific, high-power type that uses an electric arc to melt materials like scrap steel. The method of generating heat is the fundamental difference.

The term "electric furnace" describes a wide family of industrial equipment, but the "electric arc furnace" (EAF) refers to a particular member of that family. The critical difference is that an EAF melts metal using the intense heat of an electric arc, whereas other electric furnaces might use resistance heating or electromagnetic induction.

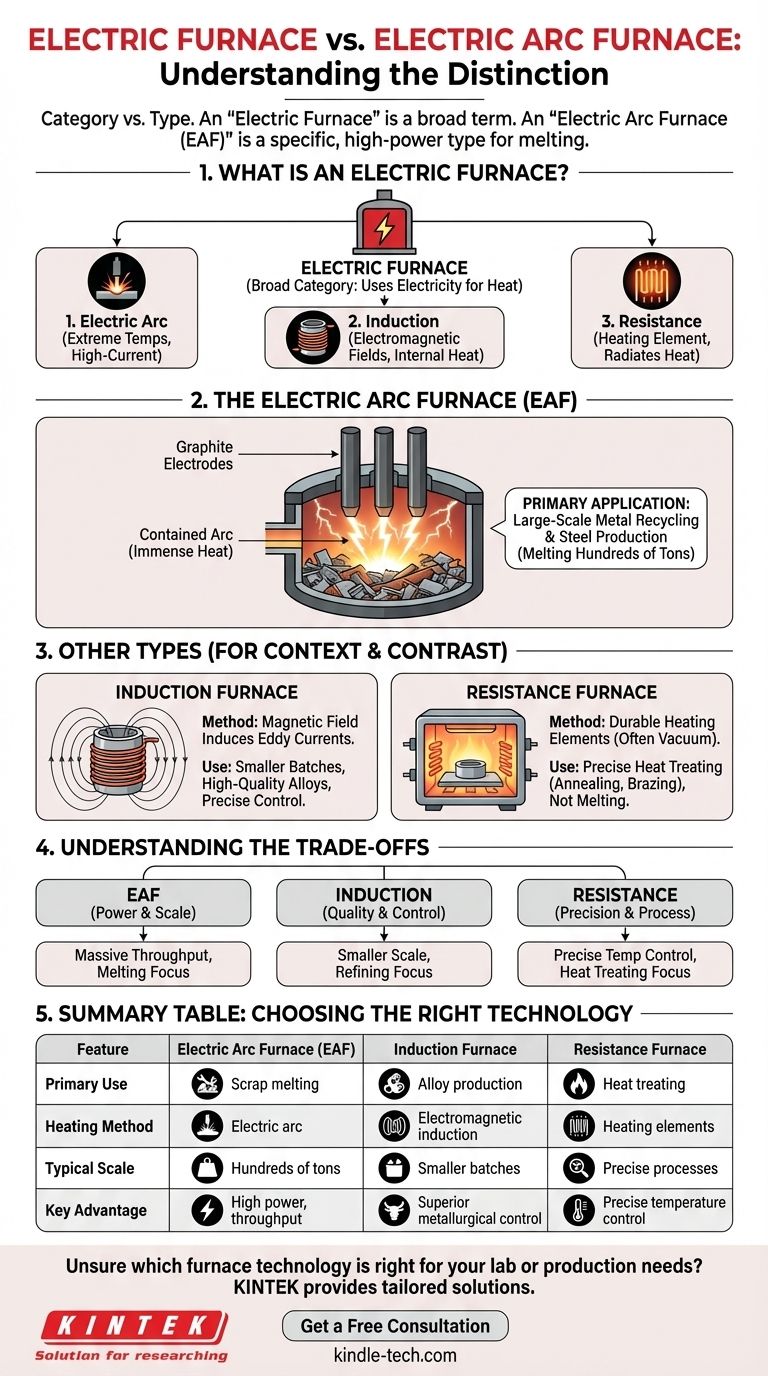

What Defines an "Electric Furnace"?

An electric furnace is any furnace that relies on electrical energy as its primary heat source. This simple definition, however, encompasses a wide range of technologies designed for very different purposes.

### The Principle of Electrical Heating

The common thread is the conversion of electricity into thermal energy. However, how this conversion happens is what differentiates one type of electric furnace from another.

### Key Heating Methods

There are three primary methods:

- Electric Arc: Creates a high-current arc (like a controlled lightning strike) to generate extreme temperatures.

- Induction: Uses electromagnetic fields to induce currents within the material itself, causing it to heat up from the inside out.

- Resistance: Passes electricity through a heating element, which glows and radiates heat, much like a toaster or electric oven.

The Mechanics of an Electric Arc Furnace (EAF)

The Electric Arc Furnace is a workhorse of modern steelmaking, designed specifically for melting massive quantities of metal at extreme temperatures.

### The Core Principle: A Contained Arc

An EAF operates by passing a powerful three-phase electric current through large graphite electrodes. These electrodes are lowered into a chamber filled with metal scrap or other raw materials.

An arc is struck between the electrodes and the metal charge itself. This arc generates immense heat, rapidly melting the metal.

### Primary Applications

EAFs are the go-to technology for large-scale metal recycling. They are predominantly used to melt down shredded scrap metal, large beams, and other steel materials to produce new steel.

### Direct vs. Indirect Arc

There are two main configurations. In a direct arc furnace, the arc makes direct contact with the metal, ensuring rapid and efficient heating. In an indirect arc furnace, the arc is struck between two electrodes above the metal, transferring heat via radiation.

Other Types of Electric Furnaces for Context

Understanding the EAF is clearer when you see what it is not. Other electric furnaces serve entirely different industrial needs.

### Induction Furnaces

An induction furnace uses a powerful alternating current to create a magnetic field. This field induces eddy currents within the metal charge, generating heat without any external contact or arc.

They are often used for producing smaller batches of high-quality alloy steels and steel castings where precise control over the metallurgy is required.

### Resistance (Vacuum) Furnaces

Many vacuum furnaces are a type of electric resistance furnace. They use durable heating elements to heat a chamber to precise temperatures, often for heat treating rather than melting.

While electric versions can reach temperatures up to 2,400°F, they are typically used for applications like hardening, brazing, or annealing parts without altering their shape.

Understanding the Trade-offs

Each type of electric furnace technology is chosen based on a specific balance of cost, scale, and metallurgical requirements.

### Scale and Throughput

EAFs are built for raw power and massive scale, capable of melting hundreds of tons of scrap steel in a single cycle.

Induction furnaces operate on a smaller scale, making them more suitable for specialty foundries producing specific alloys with more refined quality requirements.

### Metallurgical Function

Historically, the EAF has been considered superior for its metallurgical capabilities in large-scale operations. However, modern induction furnace technology has advanced significantly.

These advancements allow modern induction furnaces to produce very high-quality materials, including super low carbon stainless steel and even superalloys.

### Temperature and Process

EAFs are designed for one primary goal: extreme heat for melting. Resistance furnaces, by contrast, are about precise temperature control for processes that happen below the melting point, highlighting their distinct roles.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the intended industrial process and desired outcome.

- If your primary focus is recycling massive volumes of steel scrap: The Electric Arc Furnace (EAF) is the definitive technology for its power, scale, and efficiency in melting.

- If your primary focus is producing smaller batches of high-quality, specialized steel alloys: An induction furnace offers superior metallurgical control for more refined applications.

- If your primary focus is heat treating, annealing, or brazing finished parts: An electric resistance furnace (often in a vacuum) provides the precise temperature control needed without melting the material.

Ultimately, understanding the specific heating mechanism—arc, induction, or resistance—is the key to identifying the right tool for the job.

Summary Table:

| Feature | Electric Arc Furnace (EAF) | Induction Furnace | Resistance Furnace |

|---|---|---|---|

| Primary Use | Large-scale scrap metal melting | High-quality alloy production | Heat treating, annealing, brazing |

| Heating Method | Electric arc (direct/indirect) | Electromagnetic induction | Heating elements (resistance) |

| Typical Scale | Hundreds of tons | Smaller batches | Precise, controlled processes |

| Key Advantage | High power, massive throughput | Superior metallurgical control | Precise temperature control |

Unsure which furnace technology is right for your lab or production needs? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing tailored solutions for everything from large-scale melting to precise heat treatment processes. Contact us today using the form below to discuss your specific requirements and discover how our expertise can optimize your operations.

Visual Guide

Related Products

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does GIA identify lab grown diamonds? Uncover the Science Behind Diamond Origin Verification

- What are the main components of an industrial furnace? Explore Essential Elements for Precision Heating

- What is the demand for synthetic diamonds? Rising Popularity for Ethical & Affordable Gems

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration

- Which institutions have adjusted their ULT freezer set points to -70°C? Save Energy Without Risking Samples

- What are the properties of pyrolysis bio-oil? A Deep Dive into Its Unique Chemical Profile

- What are the two methods of control of corrosion? Master the Strategies for Metal Protection

- What is the application of reactive sputtering? Synthesize High-Performance Compound Films