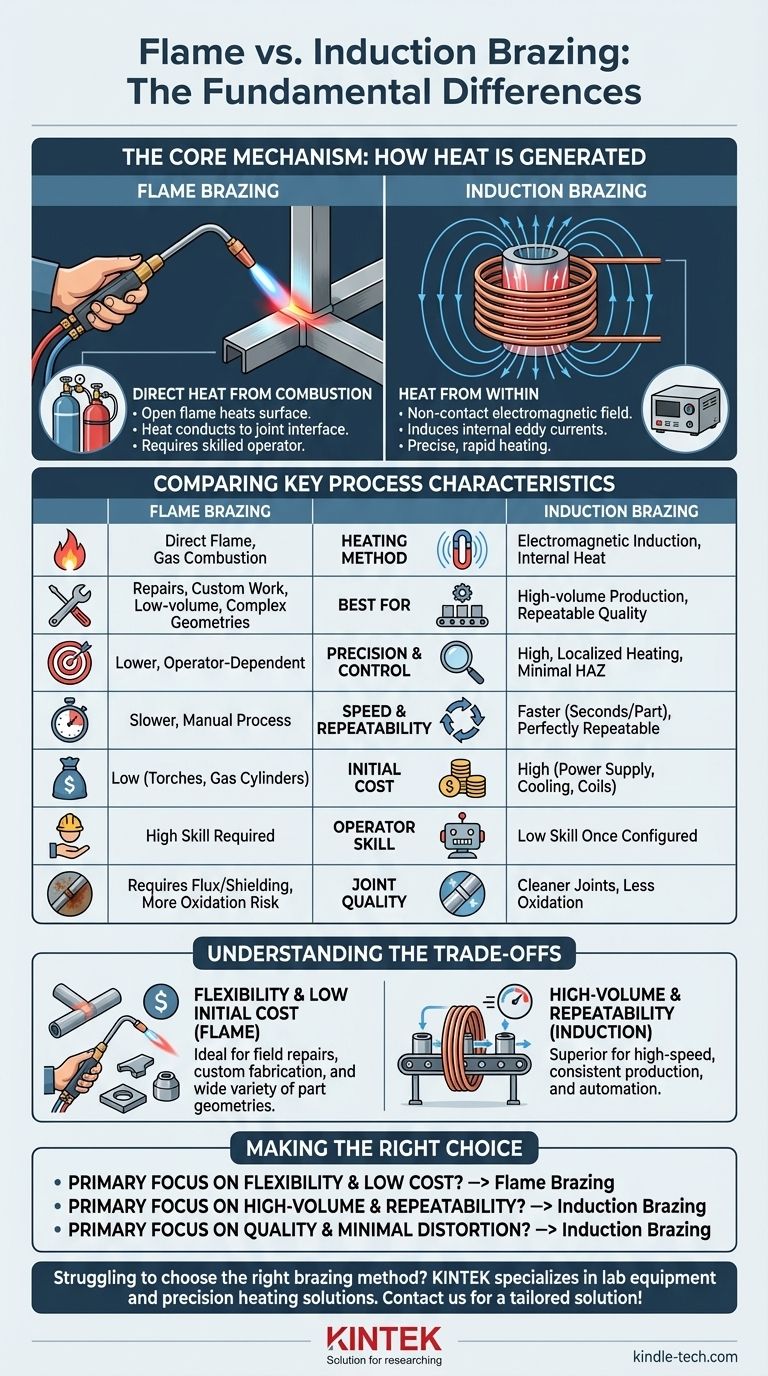

The fundamental difference between flame brazing and induction brazing lies entirely in the method used to generate heat. Flame brazing uses the direct heat from the combustion of gases, like an oxy-acetylene torch, while induction brazing uses a non-contact electromagnetic field to generate heat directly within the parts being joined.

The choice between them is a classic engineering trade-off: Flame brazing offers flexibility and low initial cost, making it ideal for repairs and custom work. Induction brazing provides unmatched speed, precision, and repeatability, making it the superior choice for high-volume manufacturing.

The Core Mechanism: How Heat is Generated

To understand the practical differences, you must first grasp how each process delivers thermal energy to the joint.

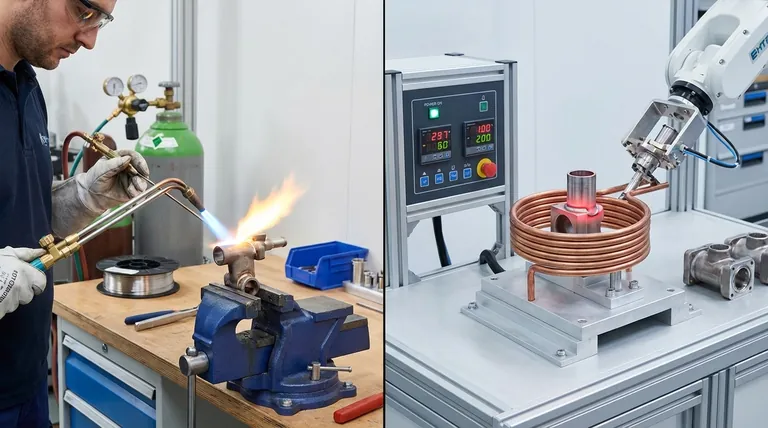

Flame Brazing: Direct Heat from Combustion

Flame brazing is the traditional method, using a torch to burn a fuel gas (like acetylene or propane) with oxygen. This open flame is applied directly to the surface of the parts near the joint area.

The operator manually moves the torch to heat the base metals evenly until they are hot enough to melt the brazing filler metal. The process relies entirely on the thermal conduction of heat from the surface of the part to the joint interface.

Induction Brazing: Heat from Within

Induction brazing is a more advanced, non-contact process. It uses a high-frequency alternating current passed through a copper coil.

This coil creates a powerful, rapidly changing magnetic field. When the metal parts are placed within this field, the field induces electrical eddy currents inside the parts themselves. The material's natural resistance to these currents generates precise, rapid, and internal heat.

Comparing Key Process Characteristics

The difference in heating method creates significant downstream effects on process control, speed, and the quality of the final product.

Precision and Control

Induction heating is exceptionally precise. The heat is generated only where the magnetic field is strongest, which can be tightly controlled by the shape and proximity of the induction coil. This allows for very localized heating, minimizing the heat-affected zone (HAZ) and reducing the risk of part distortion.

Flame heating is far less precise. The heat from a flame is convective and spreads over a much larger area. It is difficult to contain the heat exactly at the joint, and control depends heavily on the skill and steady hand of the operator.

Speed and Repeatability

For production environments, induction brazing is significantly faster, often taking only a few seconds per part. Because the process is controlled by power, frequency, and time, it is perfectly repeatable. Every joint is identical, ensuring consistent quality.

Flame brazing is a slower, manual process. The time required to bring the parts to temperature varies with part size and, most importantly, operator technique. This makes it difficult to achieve perfect consistency across a large batch of parts.

Joint Quality and Oxidation

Induction brazing often produces a cleaner joint. The speed of the heating cycle minimizes the time the part spends at high temperature, which dramatically reduces oxidation.

Flame brazing exposes the parts to the products of combustion and open air for longer periods. This necessitates the use of a flux or a shielding gas to prevent oxidation and ensure the filler metal can properly wet and flow into the joint.

Understanding the Trade-offs

Neither method is universally superior; the correct choice depends entirely on your application and operational goals.

Initial Investment vs. Operating Cost

The initial cost for a flame brazing setup is very low—essentially a set of torches, regulators, and gas cylinders. This makes it accessible for any shop.

An induction heating system is a significant capital investment. It requires a power supply, a cooling system, and custom-fabricated induction coils, which can cost thousands of dollars.

Flexibility and Part Geometry

Flame brazing is extremely flexible. A skilled operator can use the same torch to braze an enormous variety of part shapes, sizes, and complex assemblies. This makes it perfect for repairs, prototyping, and low-volume production.

Induction brazing is comparatively inflexible. It is most efficient when the induction coil is designed and built specifically for the geometry of the part being brazed. Changing to a different part often requires changing the coil, making it less suitable for high-mix, low-volume work.

Operator Skill and Safety

Successful flame brazing is highly dependent on operator skill and experience. It is a craft that takes time to master. The process also involves an open flame and the storage of flammable gases, which carries inherent safety risks.

Once an induction process is configured, it requires very little operator skill to run. It becomes a simple, push-button operation. With no open flame and a more contained process, it is generally considered a safer technology.

Making the Right Choice for Your Goal

Selecting the right process is about aligning the technology's strengths with your primary objective.

- If your primary focus is flexibility and low initial cost: Flame brazing is the definitive choice for field repairs, custom fabrication, and jobs where part geometry varies widely.

- If your primary focus is high-volume production and repeatability: Induction brazing is the superior solution, offering unmatched speed, consistency, and potential for automation.

- If your primary focus is the highest joint quality and minimal part distortion: Induction brazing provides a distinct advantage due to its precise, rapid, and localized heating.

Ultimately, choosing the correct heating method is the first step toward a successful and efficient brazing operation.

Summary Table:

| Feature | Flame Brazing | Induction Brazing |

|---|---|---|

| Heating Method | Direct flame from gas combustion | Electromagnetic field induces internal heat |

| Best For | Repairs, custom work, low-volume, complex geometries | High-volume production, repeatable quality |

| Precision & Control | Lower (operator-dependent) | High (localized heating, minimal HAZ) |

| Speed | Slower, manual process | Faster (seconds per part), repeatable |

| Initial Cost | Low | High (requires specialized equipment) |

| Operator Skill | High skill required | Low skill once configured |

| Joint Quality | Requires flux/shielding gas | Cleaner joints, less oxidation |

Struggling to choose the right brazing method for your lab or production line? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision heating solutions. Whether you require the flexibility of flame brazing for custom projects or the speed and repeatability of induction brazing for high-volume manufacturing, our experts can help you select the ideal equipment to enhance efficiency and joint quality. Contact us today to discuss your specific application and get a tailored solution!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Small Injection Molding Machine for Lab Use

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the types of induction melting furnace? Coreless, Channel, and VIM Explained

- What are the advantages of induction casting? Superior Speed, Control, and Purity for High-Performance Metals

- What is induction furnaces based on the heating effect of? Unlock Faster, Cleaner Metal Melting

- Can Aluminium be melted in induction furnace? Yes, for Faster, Cleaner Melting

- What is the temperature range of the induction melting furnace? Find the Right Heat for Your Metals

- What is the melting process in an induction furnace? A Guide to Clean, Efficient Metal Melting

- How does the pouring mechanism of a vacuum induction degassing pouring (VIDP) furnace operate? Unlock the Secret to High-Purity Metal Production

- How do you calculate the power consumption of an induction furnace? Optimize Your Melting Process