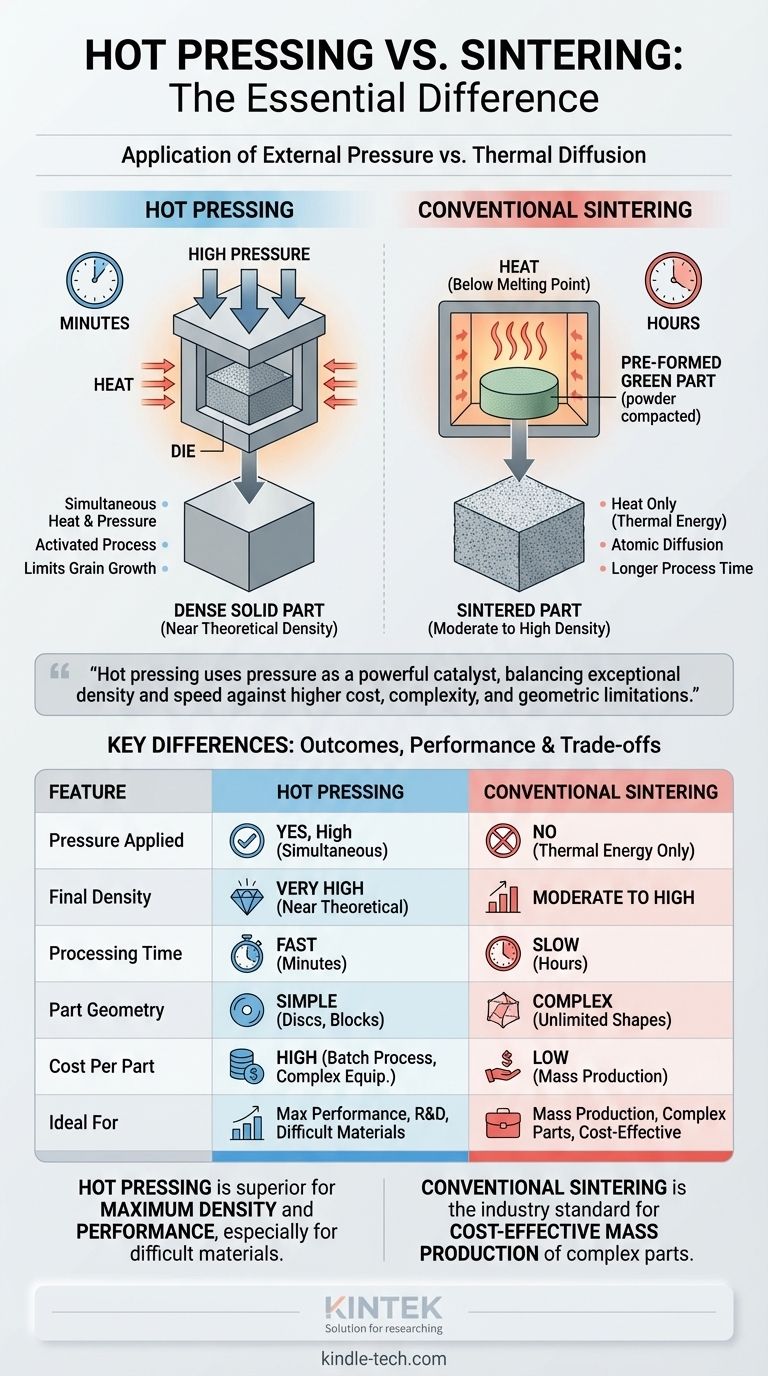

At its core, the primary difference between hot pressing and sintering lies in the application of external pressure. Hot pressing applies high pressure and heat simultaneously to a powder in a die to form a dense solid part. Conventional sintering, in contrast, involves heating a pre-formed or loose powder to a high temperature without the application of external pressure, allowing the particles to bond and densify through atomic diffusion.

While both processes use heat to fuse powders into a solid mass, hot pressing uses pressure as a powerful catalyst. This makes it a trade-off: you gain exceptional density and speed at the expense of higher cost, complexity, and limitations on part geometry.

The Fundamental Process: Heat vs. Heat and Pressure

The distinction in how pressure is used fundamentally changes the mechanism of densification.

How Conventional Sintering Works

Conventional sintering begins with a "green" part, which is powder compacted at room temperature (cold pressing) or held loosely in a mold.

This part is then placed in a furnace and heated to a temperature below its melting point. At this temperature, atoms diffuse across the boundaries of the particles, causing them to fuse together and gradually reduce the empty space, or porosity, between them.

This process relies entirely on thermal energy and can take several hours to complete.

How Hot Pressing Works

Hot pressing combines compaction and sintering into a single step. Powder is placed directly into a die, which is then heated while a large external pressure is applied.

The pressure has two major effects. First, it forces the powder particles into intimate contact, accelerating atomic diffusion. Second, it can induce plastic deformation, physically forcing material to flow and fill the voids.

This combined action makes hot pressing an "activated" process, achieving densification in minutes rather than hours.

Key Differences in Outcomes and Performance

The choice between these methods directly impacts the final product's quality, the time it takes to produce it, and the materials you can use.

Density and Porosity

Hot pressing consistently produces parts with higher final density and lower porosity. The external pressure is extremely effective at eliminating the last few percent of residual pores that can be difficult to remove with conventional sintering alone.

This leads to superior mechanical properties, such as higher strength and hardness.

Processing Time

Hot pressing is significantly faster. As noted in process data, densification can be achieved in as little as 3-10 minutes.

Conventional sintering is a much slower process, often requiring furnace cycles of 1-2 hours or more to achieve the desired density.

Material Properties

Because hot pressing can achieve full density at lower temperatures and for shorter times, it can help limit grain growth. A finer grain structure often translates to improved material toughness and strength.

This makes it ideal for advanced ceramics like silicon carbide or nitrides, which are notoriously difficult to sinter to full density conventionally.

Understanding the Trade-offs: Cost and Complexity

While hot pressing offers superior performance, these benefits come with significant practical and economic trade-offs.

Equipment and Process Complexity

A hot press is a far more complex and expensive piece of machinery than a standard sintering furnace. It must be able to withstand extreme temperatures and high mechanical pressures simultaneously.

The dies used in hot pressing must also be made from materials that can survive these conditions, such as graphite or ceramic composites, adding to the operational cost.

Production Cost and Throughput

Hot pressing is typically a batch process used to produce one part (or a small number of parts) at a time. This, combined with the high equipment cost, results in a high cost per part.

Conventional sintering is far better suited for mass production. Processes like metal injection molding (MIM) can produce thousands of complex parts that are then sintered together in a large furnace, leading to a much lower cost per part.

Geometric Limitations

Hot pressing is generally restricted to simple shapes, such as discs, blocks, and cylinders. The uniaxial pressure application makes it difficult to produce parts with complex geometries, undercuts, or internal cavities.

Conventional sintering, especially when paired with forming methods like injection molding, can create parts of almost unlimited geometric complexity.

Making the Right Choice for Your Goal

Selecting the correct process requires a clear understanding of your project's final objective, balancing material performance against manufacturing cost and scale.

- If your primary focus is achieving maximum density and performance, especially for difficult-to-sinter materials: Hot pressing is the superior choice, providing unparalleled density and mechanical properties.

- If your primary focus is cost-effective mass production of geometrically complex parts: A workflow using conventional sintering is the clear industry standard.

- If your primary focus is rapid development or producing a single, high-quality component: Hot pressing provides a much faster path to a fully dense part compared to the hours-long cycle of a sintering furnace.

Ultimately, understanding this fundamental trade-off between pressure-assisted densification and thermal diffusion is the key to selecting the optimal manufacturing path.

Summary Table:

| Feature | Hot Pressing | Conventional Sintering |

|---|---|---|

| Pressure Applied | Yes, high pressure during heating | No, relies on thermal energy only |

| Final Density | Very High (near theoretical) | Moderate to High |

| Processing Time | Fast (minutes) | Slow (hours) |

| Part Geometry | Simple shapes (discs, blocks) | Complex shapes possible |

| Cost Per Part | High | Low (for mass production) |

| Ideal For | Maximum performance, R&D, hard-to-sinter materials | Mass production, complex parts, cost-effectiveness |

Still unsure which process is right for your specific material or application?

The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing the tools and expertise you need for advanced materials processing. Whether you're developing a new ceramic component or scaling up production, we can help you select the right technology to achieve your goals for density, performance, and cost.

Contact our team today for a personalized consultation and discover how KINTEK solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- Why is precise temperature control essential for vacuum hot pressing? Master Aluminum Matrix Composite Fabrication

- What is the process of plasma sintering? Achieve Rapid, High-Performance Material Densification

- What is spark plasma sintering process? Fast-Track to Dense, Fine-Grained Materials

- Why use vacuum in hot-press sintering for boron carbide? Achieve Superior Density and Material Purity

- What is the primary function of a vacuum hot pressing furnace? Unlock High-Density Boron Carbide Composites

- What is the core role of a vacuum hot press furnace in composites? Master Precision Bonding and Densification

- What are the benefits of utilizing a Vacuum Hot Press (VHP) for Mg3Sb2? Maximize Thermoelectric Efficiency Today

- What is the function of graphite material when preparing Ga-LLZO sintered bodies? Ensure Sample Integrity in HIP