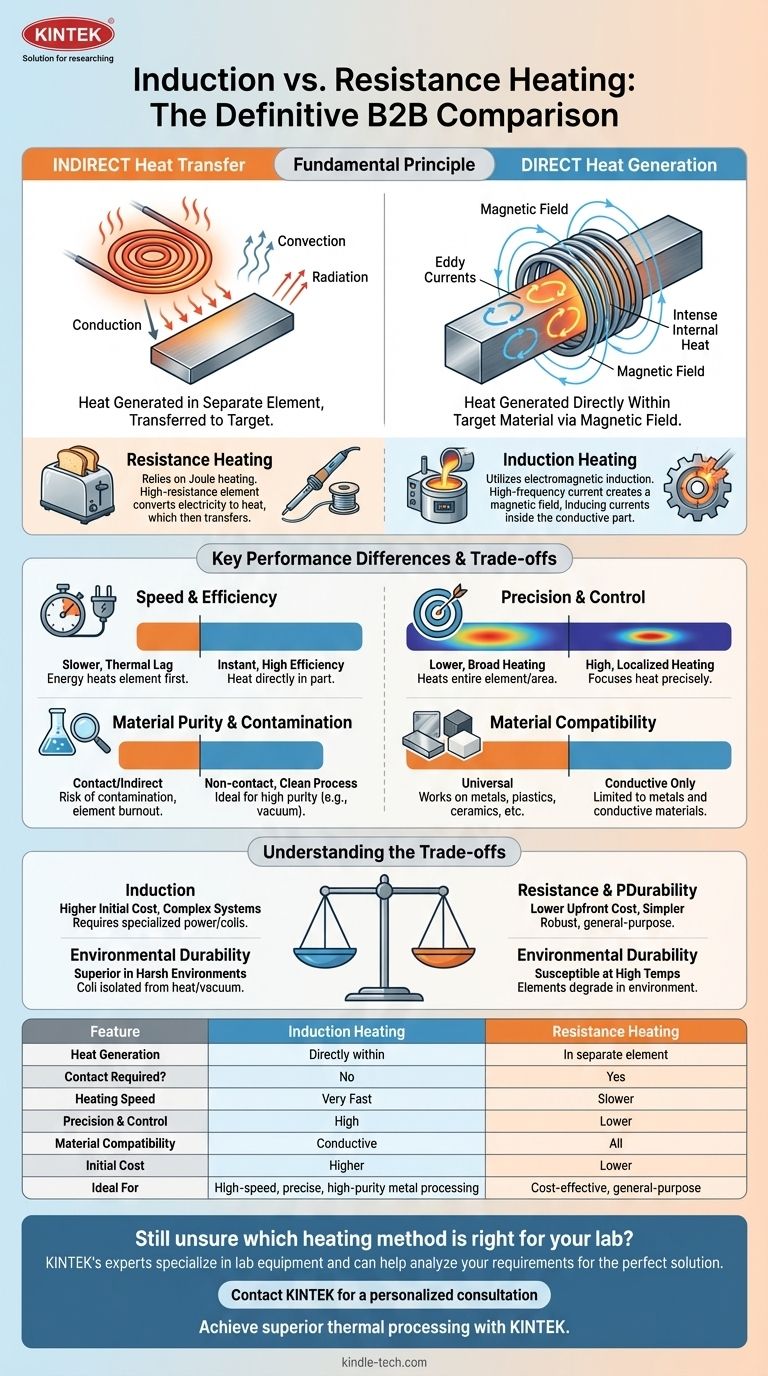

The fundamental difference lies in where and how the heat is generated. Induction heating uses a magnetic field to generate heat directly within the target material itself, while resistance heating generates heat in a separate element and then transfers that heat to the target material through contact or radiation.

The core distinction is simple: induction is a direct, non-contact heating method that turns the workpiece into its own heat source. Resistance is an indirect method that relies on transferring heat from an external hot element to the workpiece.

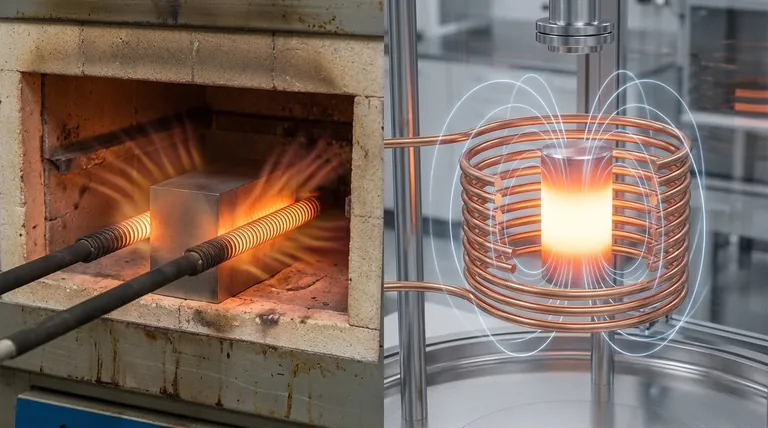

The Fundamental Principle: Direct vs. Indirect Heat

To understand the practical implications, you must first grasp the core mechanisms. The method of heat generation dictates the efficiency, speed, and precision of each process.

How Resistance Heating Works

Resistance heating is the most common form of electric heating. It operates on the principle of Joule heating.

An electric current is passed through a material with high electrical resistance, often a dedicated heating element like a nickel-chromium wire. This resistance converts electrical energy into heat.

That heat is then transferred to the target workpiece through conduction (physical contact), convection (air movement), or radiation. A household toaster or a conventional soldering iron are perfect examples.

How Induction Heating Works

Induction heating is a more advanced, non-contact process. It uses the principles of electromagnetic induction.

A high-frequency alternating current is passed through a copper coil. This creates a powerful, rapidly changing magnetic field around the coil.

When a conductive workpiece (like a piece of steel) is placed within this field, the field induces circular electrical currents—called eddy currents—inside the metal. The metal's own resistance to these internal currents generates intense, rapid heat from within.

Key Performance Differences

The choice between induction and resistance is rarely about preference; it is about performance requirements for a specific task. Each method has distinct advantages.

Speed and Efficiency

Induction is significantly faster and more energy-efficient. Heat is generated instantly and directly within the part, minimizing the time and energy lost waiting for a separate element to heat up and transfer its energy.

Resistance heating involves thermal lag. Energy is first used to heat the resistive element, and then more energy is lost to the environment as the heat travels to the workpiece.

Precision and Control

Induction heating offers far superior precision. By shaping the induction coil and controlling the frequency, you can heat a very specific, localized area of a part without affecting the surrounding material.

Resistance heating is generally less precise. It tends to heat the entire element and, through conduction or radiation, a broader area of the workpiece.

Material Purity and Contamination

Induction is a clean, non-contact process. Because the coil itself does not get hot and never touches the material, it is ideal for high-purity applications like vacuum furnaces or melting medical-grade alloys.

As noted in furnace applications, induction avoids the use of graphite electrodes required by some other methods, which eliminates the risk of carbon contamination. This is critical when producing very low-carbon steels.

Understanding the Trade-offs

Neither technology is universally superior. The right choice depends on balancing performance benefits against practical constraints.

Complexity and Cost

Induction systems are more complex. They require a specialized high-frequency power supply and often need custom-designed coils for specific applications, leading to a higher initial investment.

Resistance heating systems are mechanically simpler, more robust, and generally have a lower upfront cost, making them a common choice for general-purpose heating.

Material Compatibility

This is a critical limitation. Induction heating only works on electrically conductive materials, primarily metals. Its effectiveness also varies based on the material's magnetic permeability and resistivity.

Resistance heating is material-agnostic. Through conduction and radiation, it can effectively heat metals, plastics, ceramics, and other non-conductive materials.

Environmental Durability

In harsh environments like a vacuum, induction has a distinct advantage. The coil can be placed outside the vacuum chamber, isolated from extreme heat or chemical reactions.

Resistance elements must exist within the heated environment, making them susceptible to degradation and burnout at very high temperatures, which can present insulation challenges.

Making the Right Choice for Your Application

Selecting the correct technology requires aligning its core strengths with your primary goal.

- If your primary focus is speed, precision, and purity: Choose induction heating for its rapid, localized, and non-contaminating process, especially for metals.

- If your primary focus is low cost and material versatility: Choose resistance heating for its simplicity, lower initial investment, and ability to heat non-conductive materials.

- If your primary focus is performance in extreme environments: Choose induction for high-vacuum or ultra-high-temperature applications where heating element durability is a concern.

Ultimately, understanding the physics of direct versus indirect heating empowers you to select the right tool for the technical and financial needs of your project.

Summary Table:

| Feature | Induction Heating | Resistance Heating |

|---|---|---|

| Heat Generation | Directly within the material (via eddy currents) | In a separate heating element |

| Contact Required? | No (non-contact) | Yes (indirect, via conduction/radiation) |

| Heating Speed | Very Fast | Slower (thermal lag) |

| Precision & Control | High (localized heating) | Lower (broader heating) |

| Material Compatibility | Electrically conductive materials (e.g., metals) | All materials (metals, plastics, ceramics) |

| Initial Cost | Higher | Lower |

| Ideal For | High-speed, precise, high-purity metal processing | Cost-effective, general-purpose heating of various materials |

Still unsure which heating method is right for your lab's specific materials and processes?

The choice between induction and resistance heating is critical for the efficiency and success of your work. KINTEK's experts specialize in lab equipment and consumables, and we can help you analyze your application requirements to recommend the perfect solution.

We provide reliable, high-performance heating systems tailored to laboratory needs, ensuring optimal results for your research or production.

Contact KINTEL today for a personalized consultation and let us help you achieve superior thermal processing!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures