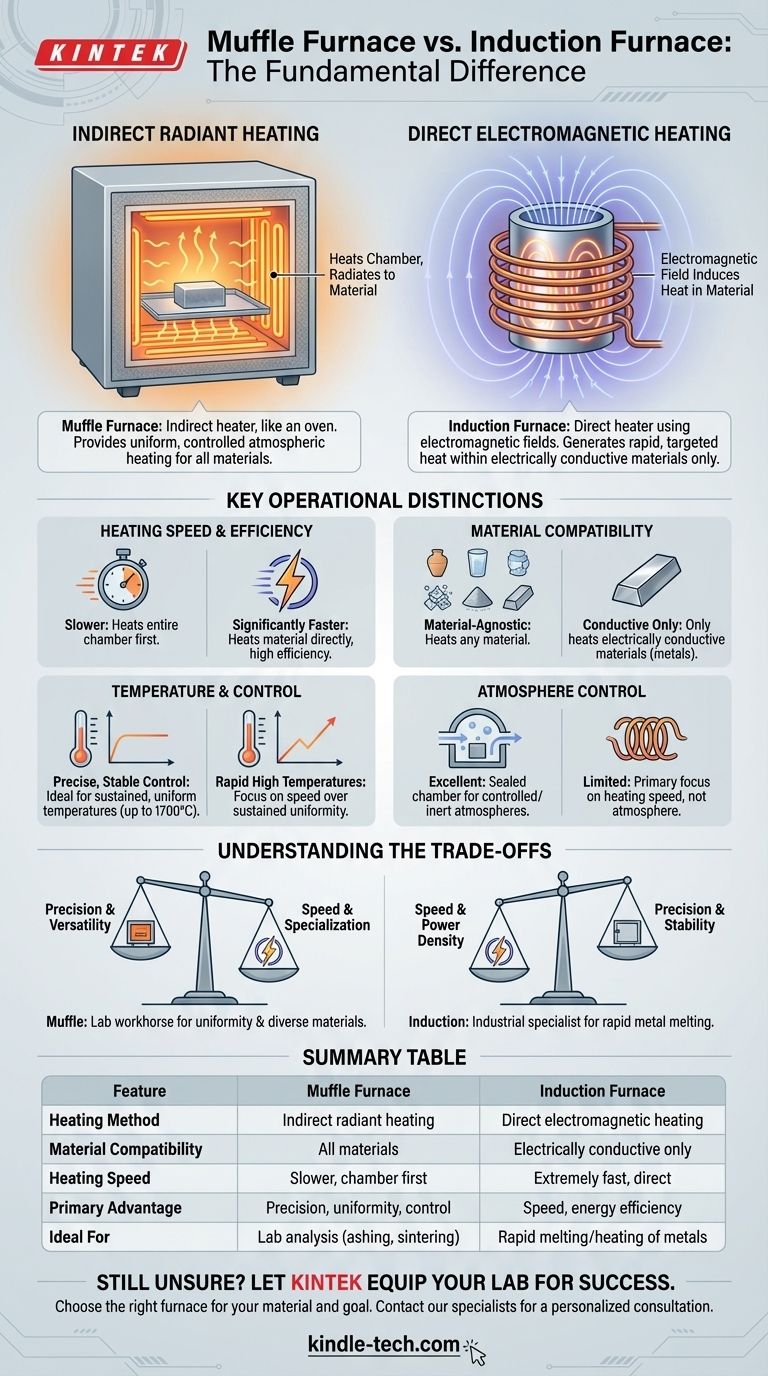

The fundamental difference between a muffle furnace and an induction furnace lies in their heating method. A muffle furnace is an indirect heater; it heats an insulated chamber, which then radiates heat onto the material inside, much like a conventional oven. In contrast, an induction furnace is a direct heater that uses an electromagnetic field to generate heat within the material itself.

At its core, the choice is between two distinct principles. Muffle furnaces provide slow, uniform, and controlled atmospheric heating for a wide variety of materials. Induction furnaces deliver extremely rapid, targeted heating exclusively for electrically conductive materials.

The Fundamental Difference: How Heat is Generated

To select the right tool, you must first understand how each one works. Their heating mechanisms are completely different, which dictates their respective strengths and applications.

Muffle Furnace: Indirect Radiant Heating

A muffle furnace is essentially a high-temperature oven. It contains heating components, such as electric wires or specialized rods, that heat the walls of an insulated chamber (the "muffle").

This heated chamber then radiates thermal energy uniformly onto the sample placed inside. Because it heats the entire space, it provides excellent temperature stability and control over the sample's environment.

Induction Furnace: Direct Electromagnetic Heating

An induction furnace operates without any conventional heating elements. Instead, it uses a powerful alternating current passed through a coil to create a strong electromagnetic field.

When an electrically conductive material (like a metal) is placed inside this field, the field induces powerful electrical currents—called eddy currents—within the material. The material's own electrical resistance causes these currents to generate intense, rapid heat from the inside out.

Key Operational Distinctions

The differences in heating mechanisms lead to significant contrasts in performance, material compatibility, and ideal use cases.

Heating Speed and Efficiency

Induction furnaces are significantly faster. By heating the material directly, they waste very little energy warming the surrounding air or chamber walls. This makes them highly efficient for tasks like melting metals.

Muffle furnaces are slower. They must first bring the entire insulated chamber up to the target temperature before the sample can be fully heated. This ramp-up time is inherent to their design.

Material Compatibility

This is a critical dividing line. An induction furnace can only heat electrically conductive materials. It is useless for heating ceramics, glass, or other insulators.

A muffle furnace is material-agnostic. Since it relies on radiant heat, it can effectively heat any material, whether it's conductive, non-conductive, a powder, or a solid.

Temperature Range and Control

Muffle furnaces are designed for precise temperature control over long periods. Their maximum temperature is determined by the heating elements used:

- Electric heating wires: Up to 1200°C

- Silicon-carbon rods: Up to 1400°C

- Silicon molybdenum rods: Up to 1700°C

Induction furnaces can achieve extremely high temperatures very quickly, but their primary advantage is speed rather than sustained, uniform stability across a large chamber.

Atmosphere Control

Because a muffle furnace is a sealed, enclosed chamber, it is perfectly suited for processes that require a specific, controlled, or inert atmosphere. This is crucial for preventing oxidation or contamination during heat treatment.

Understanding the Trade-offs

Neither technology is universally superior; they are specialized tools with distinct advantages and limitations.

Precision vs. Speed

A muffle furnace offers superior temperature uniformity and precision. It is the standard for laboratory work like gravimetric analysis, sintering, or quantitative analysis where exact, stable temperatures are non-negotiable.

An induction furnace prioritizes speed and power density. It excels in industrial settings where the goal is to melt or forge large quantities of metal as quickly as possible.

Versatility vs. Specialization

The muffle furnace is a versatile workhorse. Its ability to heat any material makes it a fixture in research, development, and quality control labs across many industries.

The induction furnace is a focused specialist. Its application is almost entirely centered on the metallurgy and processing of conductive metals.

Making the Right Choice for Your Goal

Your final decision should be based entirely on your material and your desired outcome.

- If your primary focus is precise, uniform heating of various materials (conductive or not): A muffle furnace is the correct choice for its control, stability, and versatility.

- If your primary focus is rapidly melting or heating electrically conductive metals: An induction furnace offers unmatched speed and efficiency by heating the material directly.

- If you are performing controlled laboratory analysis like annealing, ashing, or sintering: A muffle furnace provides the necessary temperature stability and atmospheric control for reliable results.

Understanding whether you need to heat the environment or the material itself is the key to selecting the right furnace for your work.

Summary Table:

| Feature | Muffle Furnace | Induction Furnace |

|---|---|---|

| Heating Method | Indirect radiant heating (like an oven) | Direct electromagnetic heating |

| Material Compatibility | All materials (metals, ceramics, powders) | Electrically conductive materials only |

| Heating Speed | Slower, heats entire chamber first | Extremely fast, heats material directly |

| Primary Advantage | Precision, uniformity, and atmosphere control | Speed and energy efficiency for metals |

| Ideal For | Lab analysis (ashing, sintering), heat treatment | Rapid melting and heating of metals |

Still Unsure Which Furnace is Right for Your Application?

Choosing between a muffle furnace and an induction furnace is critical for achieving accurate and efficient results. KINTEK, your trusted partner in laboratory equipment, can help you make the right choice.

We specialize in providing high-quality lab furnaces and consumables tailored to your specific needs. Whether you require the versatile, controlled heating of a muffle furnace for research and development or the rapid, targeted power of an induction furnace for metallurgy, our experts are here to guide you.

Let KINTEK equip your lab for success. Contact our specialists today for a personalized consultation and find the perfect furnace solution for your materials and processes.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the function of a high-temperature muffle furnace for duplex stainless steel? Optimize Alloy Performance

- What is the role of muffle furnaces in Ni-based catalyst preparation? Optimize Syngas Reforming Efficiency

- What are the methods of debinding? A Guide to Thermal, Solvent, and Catalytic Removal

- What is the role of a box furnace in the processing of Na3PS4? Enhance Ionic Conductivity & Material Crystallization

- What is the muffle furnace digital temperature controller? The Brain Behind Precise High-Temperature Control

- What role does a high-temperature muffle furnace play in LDH-derived photocatalysts? Engineer Superior Metal Oxides

- What is the importance of precise programmed temperature control in a high-temperature furnace? Master Co-Sintering

- Why is a high-temperature muffle furnace necessary for producing calcium-based catalysts? Unlock Waste Potential.