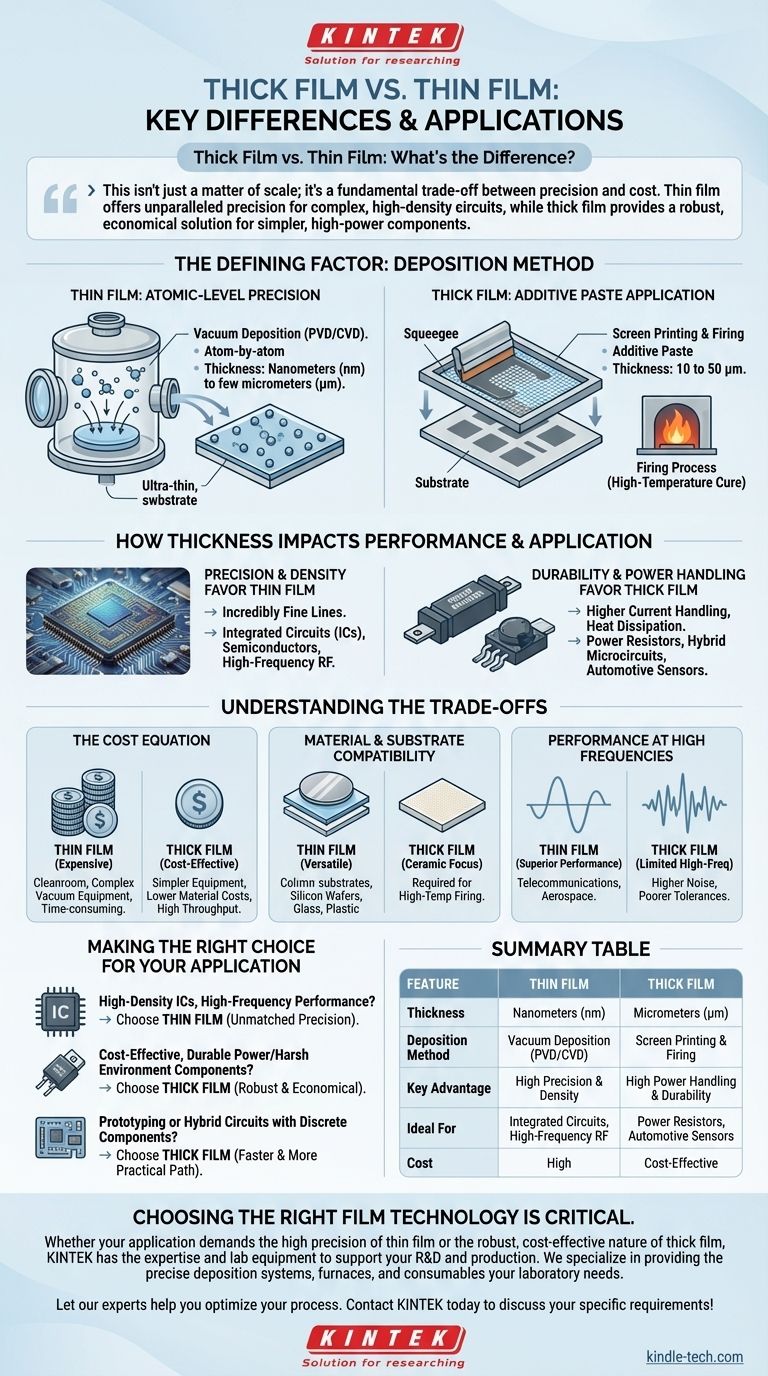

At its core, the difference between thick film and thin film technology comes down to two key factors: the deposition method and the resulting material thickness. Thin films are built atom-by-atom in a vacuum, resulting in layers measured in nanometers. Thick films are applied as a paste using a screen-printing process, creating much thicker layers measured in micrometers.

This isn't just a matter of scale; it's a fundamental trade-off between precision and cost. Thin film offers unparalleled precision for complex, high-density circuits, while thick film provides a robust, economical solution for simpler, high-power components.

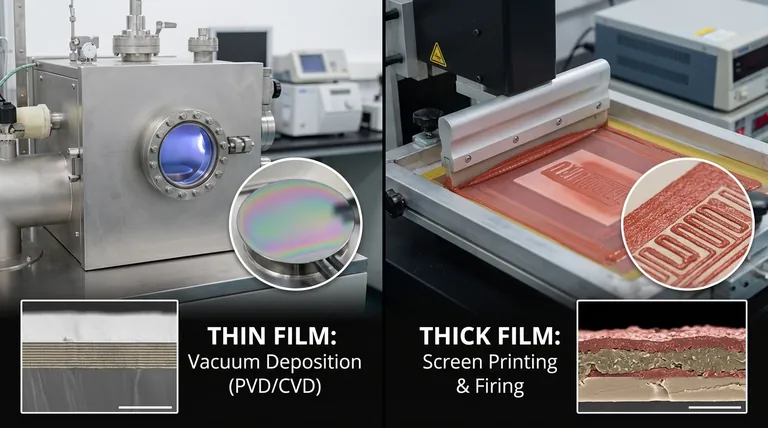

The Defining Factor: Deposition Method

The "thick" vs. "thin" distinction originates entirely from how the material is applied to the substrate. This process dictates every subsequent characteristic of the technology.

Thin Film: Atomic-Level Precision

Thin film deposition occurs in a vacuum chamber. Processes like Physical Vapor Deposition (PVD) (e.g., sputtering) or Chemical Vapor Deposition (CVD) are used.

These methods deposit material one molecule or atom at a time, creating an extremely uniform and pure layer. The resulting film thickness is typically between a few nanometers (nm) and a few micrometers (µm).

Thick Film: Additive Paste Application

Thick film technology is an additive process, most commonly screen printing. It functions much like stenciling.

A specialized paste—containing conductive, resistive, or dielectric particles—is pushed through a patterned screen onto a substrate, usually ceramic. The part is then fired in a high-temperature furnace to cure the paste, binding it to the substrate. This creates layers that are typically 10 to 50 µm thick.

How Thickness Impacts Performance and Application

The manufacturing process and resulting thickness directly influence what each technology excels at.

Precision and Density Favor Thin Film

The atomic-level control of thin film deposition allows for incredibly fine lines and tight tolerances. This is what enables the creation of modern microelectronics.

This precision is essential for integrated circuits (ICs), semiconductors, and high-frequency RF components where even minute variations can impact performance.

Durability and Power Handling Favor Thick Film

The greater volume of material in thick film layers makes them inherently more robust. They can handle higher currents and dissipate more heat.

This makes thick film ideal for power resistors, hybrid microcircuits, and automotive sensors that must withstand significant thermal and physical stress.

Understanding the Trade-offs

Choosing between these technologies requires a clear understanding of their inherent limitations and benefits.

The Cost Equation

Thin film is expensive. It requires a cleanroom environment, complex vacuum equipment, and a time-consuming deposition process.

Thick film is significantly more cost-effective. The equipment is simpler, material costs are lower, and the manufacturing throughput is much higher, making it ideal for mass production of simpler components.

Material and Substrate Compatibility

Thin film processes are versatile and can be used on a wide range of substrates, including silicon wafers, glass, and plastics.

Thick film is almost always applied to ceramic substrates (like alumina) because they can withstand the high temperatures required for the firing process.

Performance at High Frequencies

Thin film's precise geometric definition and purer materials result in superior performance for high-frequency applications, such as those in telecommunications and aerospace.

Thick film resistors and conductors tend to have higher noise and poorer tolerances, which can limit their use in sensitive, high-frequency designs.

Making the Right Choice for Your Application

The correct technology is the one that best aligns with your project's balance of performance, durability, and budget.

- If your primary focus is high-density integrated circuits or high-frequency performance: Thin film is the only viable choice due to its unmatched precision.

- If your primary focus is cost-effective, durable components for power applications or harsh environments: Thick film offers a robust and economical solution.

- If you are prototyping or producing hybrid circuits with discrete components: Thick film's simpler process often provides a faster and more practical path.

Ultimately, understanding these fundamental differences empowers you to select the technology that aligns perfectly with your engineering and business goals.

Summary Table:

| Feature | Thin Film | Thick Film |

|---|---|---|

| Thickness | Nanometers (nm) | Micrometers (µm) |

| Deposition Method | Vacuum Deposition (PVD/CVD) | Screen Printing & Firing |

| Key Advantage | High Precision & Density | High Power Handling & Durability |

| Ideal For | Integrated Circuits, High-Frequency RF | Power Resistors, Automotive Sensors |

| Cost | High | Cost-Effective |

Choosing the right film technology is critical for your project's success. Whether your application demands the high precision of thin film or the robust, cost-effective nature of thick film, KINTEK has the expertise and lab equipment to support your R&D and production.

We specialize in providing the precise deposition systems, furnaces, and consumables your laboratory needs. Let our experts help you optimize your process. Contact KINTEK today to discuss your specific requirements!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition