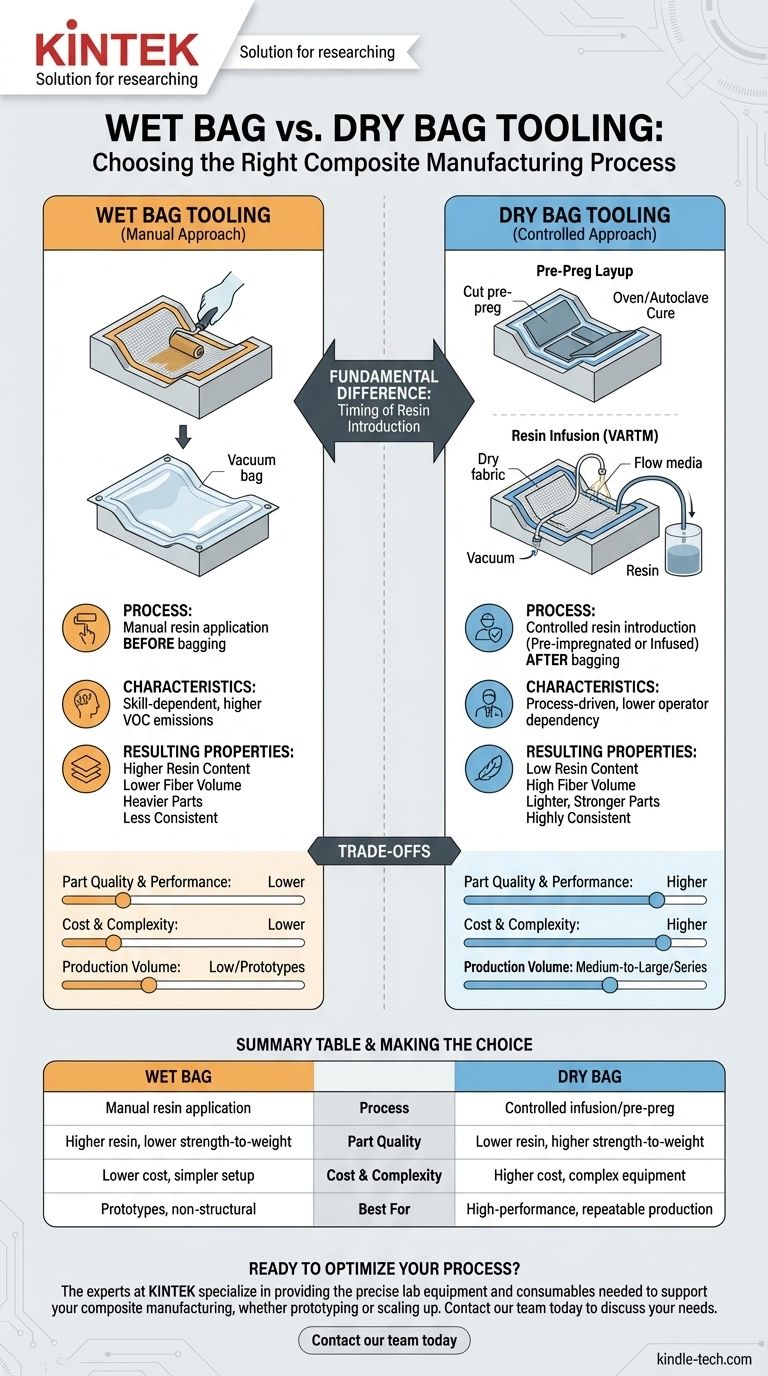

The fundamental difference between wet bag and dry bag tooling lies in when the liquid resin is introduced to the reinforcement fabric. In a wet bag process, resin is manually applied to the fabric before the vacuum bag is sealed. In a dry bag process, such as with pre-pregs or resin infusion, the bag is sealed over a dry or pre-impregnated fabric stack, and liquid resin is either already present in a controlled state or introduced afterward.

Your choice between these methods is a direct trade-off between cost and control. Wet bagging is a simpler, lower-cost process, while dry bagging methods provide superior control over the resin content, leading to lighter, stronger, and more repeatable composite parts.

Deconstructing Wet Bag Tooling (The Manual Approach)

Wet bag tooling, often called "wet lay-up with vacuum bagging," is an evolution of the most basic open-mold composites process. It adds vacuum pressure to a manual lamination to improve consolidation.

The Process at a Glance

First, dry reinforcement fabrics like fiberglass or carbon fiber are placed into a mold. Liquid resin is then poured onto the fabric and manually worked in with tools like squeegees and rollers.

After the fabric is saturated, a series of consumable materials (peel ply, release film, breather cloth) are placed on top, and the entire assembly is sealed under a vacuum bag. The vacuum pump then removes trapped air and applies atmospheric pressure to compact the laminate.

Key Characteristics

This method is highly dependent on the skill of the technician. The final quality, resin content, and void presence are directly influenced by how well the resin was applied and distributed manually.

Because the lamination occurs in an open-air environment before the bag is sealed, it can also result in higher emissions of volatile organic compounds (VOCs).

Resulting Part Properties

Wet bagging typically results in parts with a higher resin content and, therefore, a lower fiber volume fraction. This makes the final component heavier and less stiff or strong than one made with a more controlled process. The manual nature can also lead to higher void content and part-to-part inconsistency.

Deconstructing Dry Bag Tooling (The Controlled Approach)

"Dry bag" is a broader term that encompasses two primary, higher-performance manufacturing methods: pre-preg lamination and resin infusion. Both are defined by introducing the resin in a controlled manner.

Method 1: Pre-Preg Layup

In this process, the reinforcement fabric is pre-impregnated with a precise amount of catalyzed resin, known as a "pre-preg." This material is stored in a frozen state to prevent curing.

Technicians cut and place the "dry" feeling pre-preg material into the mold. The vacuum bag is then sealed, and the part is cured in an oven or autoclave, which provides both heat and elevated pressure to consolidate the laminate. No liquid resin is handled during the lay-up.

Method 2: Resin Infusion (VARTM)

Resin infusion starts with placing completely dry fabric into the mold. A complex network of tubing and flow media is arranged over the fabric stack before the vacuum bag is sealed.

Once a perfect vacuum is achieved, a resin inlet tube is opened, and the vacuum sucks a precise, pre-measured volume of liquid resin through the dry fabric, saturating it completely. This is a true closed-mold process.

Resulting Part Properties

Both dry bag methods produce parts with a low resin content and a very high, consistent fiber volume fraction. This optimization results in the lightest and strongest possible parts. The process-driven nature reduces operator dependency and yields extremely consistent, high-quality components with minimal voids.

Understanding the Trade-offs: A Head-to-Head Comparison

Choosing the right process requires a clear understanding of the compromises you are willing to make regarding performance, cost, and complexity.

Part Quality & Performance

Dry bag methods are superior. The precise control over the fiber-to-resin ratio, a critical metric in composites, is the primary reason pre-preg and infusion are used for aerospace, motorsport, and other high-performance applications. Wet bagging cannot achieve this level of optimization.

Cost & Complexity

Wet bagging is the clear winner for low cost and simplicity. The materials are cheaper, the tooling is less complex, and it requires minimal equipment—often just a mold and a vacuum pump.

Pre-preg requires expensive materials and refrigerated storage, and curing often demands a calibrated oven or a multi-million dollar autoclave. Resin infusion requires more complex bagging setups and a deeper understanding of resin flow dynamics.

Production Volume & Consistency

Wet bagging is excellent for one-off parts and prototypes. However, its manual nature makes achieving perfect consistency across multiple parts challenging.

Dry bag methods are built for repeatability. Once a process is validated for infusion or a cure cycle is set for pre-preg, you can produce nearly identical parts with confidence, making them ideal for series production.

Making the Right Choice for Your Goal

The best process is the one that aligns with the specific requirements of your project.

- If your primary focus is low-cost prototyping or non-structural components: Wet bagging provides the easiest entry point and is perfectly adequate for many applications.

- If your primary focus is the absolute maximum strength-to-weight ratio: Pre-preg layup, especially when cured in an autoclave, is the undisputed industry standard for ultimate performance.

- If your primary focus is repeatable quality for medium-to-large parts: Resin infusion offers an excellent balance, delivering near pre-preg level performance without the high material and storage costs.

Ultimately, selecting the right composite manufacturing process is about matching the method's inherent capabilities to your end goal.

Summary Table:

| Aspect | Wet Bag Tooling | Dry Bag Tooling |

|---|---|---|

| Process | Manual resin application before bagging | Controlled resin infusion or pre-preg layup |

| Part Quality | Higher resin content, lower strength-to-weight | Lower resin content, higher strength-to-weight |

| Cost & Complexity | Lower cost, simpler setup | Higher cost, more complex equipment |

| Best For | Prototypes, low-volume, non-structural parts | High-performance, repeatable production |

Ready to Optimize Your Composite Manufacturing Process?

Choosing between wet bag and dry bag tooling is critical for achieving the right balance of performance, cost, and consistency in your composite parts. The experts at KINTEK specialize in providing the precise lab equipment and consumables needed to support your composite manufacturing, whether you're prototyping with wet bagging or scaling up with dry bag methods like resin infusion.

We understand the unique challenges of laboratory and production environments. Let us help you select the right tools—from vacuum pumps and ovens to consumables—to ensure your process is efficient, repeatable, and successful.

Contact our team today to discuss your specific needs and discover how KINTEK's solutions can enhance your composite workflow.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What are the advantages of using bi-directional pressing graphite molds? Achieve Superior Density and Precision

- How do graphite molds contribute to the chemical environment during the vacuum hot pressing of Cu-Cr-Nb alloys?

- What functions do graphite molds perform during SPS and HP for LLZO ceramics? Optimize Your Sintering Process

- Can you melt gold in a graphite mold? Yes, with the right technique for professional results.

- What is a pressing die? The Precision Tool for Shaping Powder into Solid Pellets

- What is a 3 plate mold structure? Achieve Automatic Degating and Design Flexibility

- What are the advantages of multi cavity mold? Boost Production & Slash Part Costs

- Why are high-strength graphite molds required during the vacuum hot pressing process for TiAl/Ti6Al4V composites?