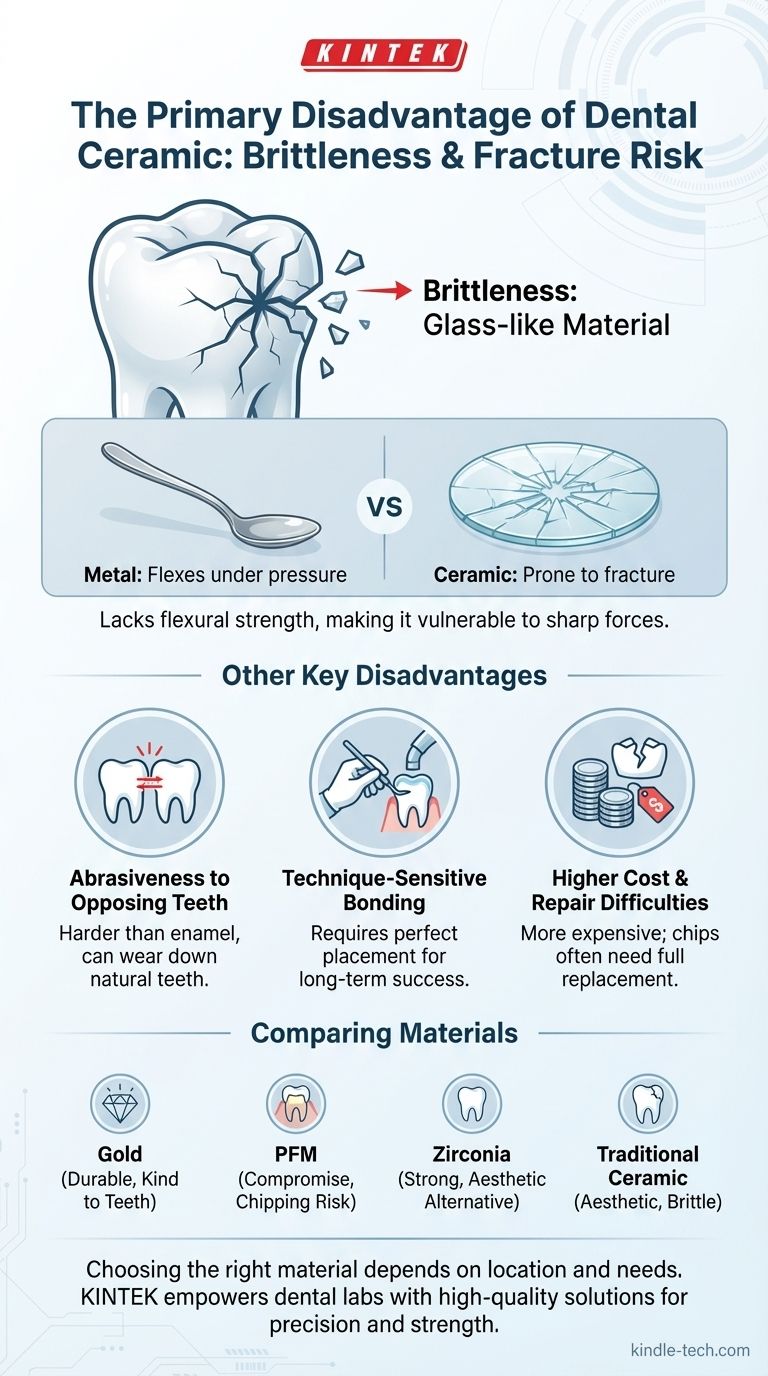

Fundamentally, the primary disadvantage of traditional dental ceramic is its brittleness. Unlike metal restorations that can bend or deform under pressure, ceramic is a glass-like material. This means that while it is very strong in compression (biting down), it can be prone to chipping or fracturing when subjected to sharp, focused forces or tensile stress.

While dental ceramics offer unparalleled aesthetics that mimic natural teeth, this benefit comes with a critical trade-off. You are exchanging the flexibility and durability of metal for superior appearance, which introduces a higher risk of fracture and potential wear on opposing teeth.

The Core Challenge of Ceramics: Brittleness

The defining weakness of traditional porcelain or feldspathic ceramics stems from their material nature. Understanding this is key to knowing when and where they are best used.

What "Brittle" Means for a Tooth

Think of the difference between dropping a glass plate and a metal spoon. The glass shatters because it cannot absorb and distribute the impact energy, while the metal spoon might dent but remains intact.

Dental ceramic behaves like the glass plate. It lacks flexural strength, which is the ability to bend before breaking. This makes it vulnerable to fracture from habits like teeth grinding (bruxism) or biting down unexpectedly on a hard object like a popcorn kernel.

When Fracture Risk Increases

The location of the restoration is critical. Back teeth, or molars, sustain immense chewing forces, making them higher-risk locations for traditional, purely aesthetic ceramics.

Front teeth are subjected to less force and are more visible, making them ideal candidates for these materials. Your specific bite and any grinding habits are the most important factors your dentist will consider.

Beyond Fracture: Other Key Considerations

While brittleness is the main concern, other factors are equally important for long-term success. A good decision requires looking at the entire picture.

Abrasiveness to Opposing Teeth

An often-overlooked disadvantage is that dental ceramic is exceptionally hard—often harder than natural tooth enamel.

Over many years, a ceramic crown can act like a slow, steady file, gradually wearing down the natural tooth it bites against. This is a significant consideration for patients with a history of grinding.

Technique Sensitivity and Bonding

Placing a ceramic restoration is less forgiving than placing a metal one. Success depends heavily on the dentist's skill in preparing the tooth and, most importantly, on the quality of the adhesive bond.

A flawless bond is necessary to integrate the ceramic with the tooth, distributing forces and sealing out bacteria. Any imperfection in this process can create a weak point that leads to premature failure.

Cost and Repair Limitations

Ceramic restorations are typically more expensive than metal or porcelain-fused-to-metal (PFM) options. This is due to the cost of the material itself and the complex, multi-step laboratory fabrication process.

Furthermore, if a ceramic crown chips, it is very difficult to repair effectively inside the mouth. In most cases, a significant chip or fracture means the entire restoration must be replaced.

Understanding the Trade-offs: Ceramic vs. Other Materials

No material is perfect. The disadvantages of ceramic become clearer when compared to the alternatives.

Compared to Gold and Metal Alloys

Gold crowns are the gold standard for durability. They are extremely strong, will not fracture, and are uniquely "kind" to opposing teeth, wearing at a rate similar to natural enamel. Their obvious disadvantage is their metallic appearance.

Compared to Porcelain-Fused-to-Metal (PFM)

PFM crowns offer a compromise. They have a strong metal substructure for durability, covered with a layer of porcelain for aesthetics. However, the porcelain can still chip off the metal, and a dark metal line can sometimes become visible at the gumline over time.

The Rise of Modern Zirconia

Zirconia is a type of ceramic, but it's in a class of its own. It is exceptionally strong and resistant to fracture, making it an excellent choice for molars. While early versions were opaque and less aesthetic, modern zirconia materials have dramatically improved translucency, offering a superb blend of strength and beauty.

Making the Right Choice for Your Restoration

The decision depends entirely on the location of the tooth, your functional needs, and your aesthetic goals. Discuss these scenarios with your dental professional.

- If your primary focus is ultimate aesthetics for a front tooth: A traditional feldspathic or glass-ceramic is often the most beautiful and life-like option, provided you don't have a history of heavy grinding.

- If your primary focus is maximum durability for a back molar: A full-gold crown remains the longest-lasting choice, but monolithic zirconia offers a powerful and highly aesthetic alternative.

- If your primary focus is a balance of strength, aesthetics, and proven performance: A porcelain-fused-to-metal (PFM) crown or a modern zirconia restoration can be an excellent all-around solution.

Ultimately, the best material is one chosen in partnership with your dentist to meet your specific clinical needs and personal priorities.

Summary Table:

| Disadvantage | Key Impact | Common in Which Ceramics? |

|---|---|---|

| Brittleness & Fracture Risk | Prone to chipping under sharp or heavy forces | Traditional Porcelain, Feldspathic Ceramics |

| Abrasiveness to Opposing Teeth | Can wear down natural enamel over time | Most Dental Ceramics |

| Technique-Sensitive Bonding | Requires perfect placement for long-term success | All Adhesive Ceramics |

| Higher Cost & Repair Difficulty | More expensive; chips often require full replacement | Traditional Porcelain, High-Strength Ceramics |

Choosing the right dental ceramic is critical for a long-lasting, beautiful restoration. At KINTEK, we specialize in high-quality dental lab equipment and consumables that empower technicians to create durable, aesthetically superior ceramic restorations. Whether you're working with traditional porcelain or modern zirconia, having the right tools ensures precision and strength.

Let KINTEK be your partner in dental excellence. Contact our experts today to discuss how our solutions can meet your specific laboratory needs and help you deliver the best possible outcomes for your patients.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs