In any sputtering process, the pressure of the background gas is a critical parameter that directly controls the quality of the final coating. Lowering the process pressure generally produces a denser, smoother, and more adherent thin film. This occurs because fewer gas molecules are present to interfere with the sputtered atoms as they travel from the source target to the substrate, allowing them to arrive with higher kinetic energy.

The core principle to understand is that chamber pressure dictates the energy of the atoms arriving at your substrate. Lower pressure enables a high-energy deposition process that creates superior film quality, while higher pressure results in a low-energy process that can lead to more porous structures.

The Fundamental Role of Pressure in Sputtering

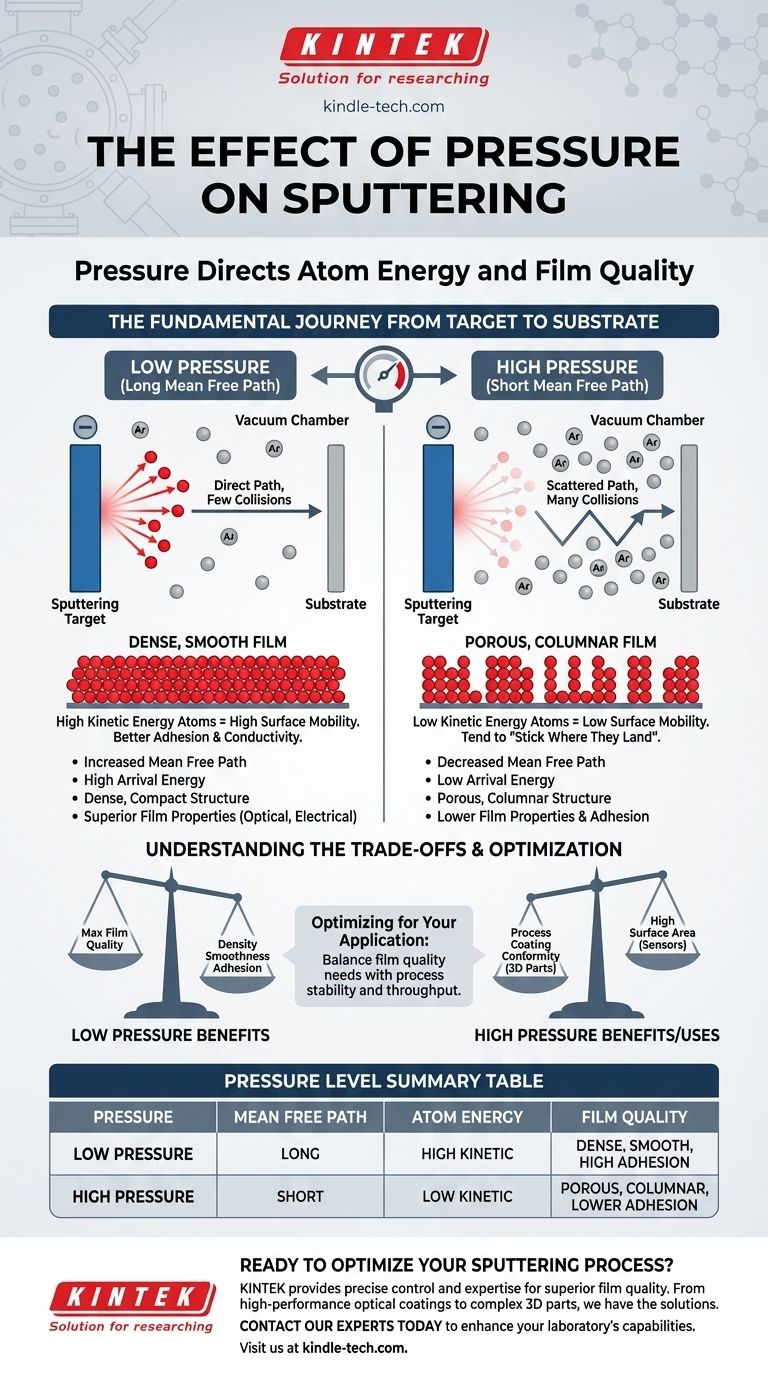

Sputtering involves creating a plasma from an inert gas, typically Argon. Positively charged Argon ions are accelerated into a negatively charged target, striking it with enough force to eject, or "sputter," atoms of the target material. These ejected atoms then travel across the vacuum chamber to coat your substrate.

The Journey from Target to Substrate

Once an atom is sputtered from the target, it begins a journey through the background gas toward the substrate. This is not an empty void; it is filled with the Argon atoms that sustain the plasma.

The path of the sputtered atom is therefore obstructed by potential collisions with these gas atoms. Each collision can alter the atom's trajectory and, more importantly, reduce its kinetic energy.

Introducing the Mean Free Path

The mean free path is the most important concept for understanding pressure's effect. It represents the average distance a particle—in this case, a sputtered atom—can travel before it collides with another particle.

How Pressure Controls Mean Free Path

The mean free path is inversely proportional to pressure.

At low pressure, there are fewer gas atoms in the chamber. This significantly increases the mean free path, allowing sputtered atoms to travel directly to the substrate with few or no collisions.

At high pressure, the density of gas atoms increases. This shortens the mean free path, making it almost certain that a sputtered atom will undergo multiple collisions on its way to the substrate.

The Consequence of Pressure Changes on Film Quality

The energy of the atoms upon arrival at the substrate surface is what ultimately determines the microstructure and physical properties of the film.

The Impact of Low-Pressure Sputtering

When sputtered atoms arrive with high kinetic energy (a result of low-pressure conditions), they have significant surface mobility. This allows them to move around, find energetically favorable sites, and fill in microscopic voids.

The result is a denser, more compact film structure. This density typically leads to superior performance, including higher reflectivity, lower electrical resistivity, and much better adhesion to the substrate.

The Impact of High-Pressure Sputtering

When sputtered atoms arrive with low kinetic energy after many collisions (a result of high-pressure conditions), they have very little surface mobility. They tend to "stick where they land."

This leads to a more porous and less dense film structure. The atoms arrange themselves in columnar grains with voids in between, which can degrade the film's mechanical and electrical properties and weaken its adhesion.

Understanding the Trade-offs

While low pressure generally yields higher-quality films, it is not always the optimal choice for every process. There are practical limitations to consider.

The Challenge of Low-Pressure Plasma

Sustaining a stable plasma becomes more difficult as pressure decreases. With fewer gas atoms available to be ionized, the plasma can become unstable or extinguish entirely, which can halt the deposition process.

Furthermore, deposition rates can sometimes decrease at extremely low pressures, as the sputtering efficiency may be linked to the ion current bombarding the target.

The Niche for High-Pressure Sputtering

While often undesirable, a porous film structure created at high pressure can be useful for specific applications. These include components requiring a high surface area, such as certain types of chemical sensors or catalysts.

Higher pressure also creates more scattering, which can be advantageous for coating complex, three-dimensional parts that are not in a direct line-of-sight from the target.

Optimizing Pressure for Your Application

Choosing the right pressure requires balancing the need for film quality against the practicalities of the deposition process.

- If your primary focus is high-performance optical or electronic films: You should operate at the lowest stable process pressure to maximize film density, smoothness, and adhesion.

- If your primary focus is coating complex, non-planar shapes: A slightly higher pressure may improve coating conformity by scattering the sputtered material more uniformly.

- If your primary focus is process stability and throughput: You must find the "sweet spot" where pressure is low enough for good film quality but high enough to maintain a stable, high-rate plasma discharge.

Ultimately, pressure is the most powerful lever you can pull to engineer the microstructure and performance of your sputtered thin film.

Summary Table:

| Pressure Level | Mean Free Path | Atom Arrival Energy | Resulting Film Quality |

|---|---|---|---|

| Low Pressure | Long | High Kinetic Energy | Dense, Smooth, High Adhesion |

| High Pressure | Short | Low Kinetic Energy | Porous, Columnar, Lower Adhesion |

Ready to optimize your sputtering process for superior film quality? KINTEK specializes in lab equipment and consumables, providing the precise control and expertise needed to achieve the perfect pressure balance for your specific application. Whether you're developing high-performance optical coatings or need to coat complex 3D parts, our solutions ensure optimal film density, adhesion, and performance. Contact our experts today to discuss how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis