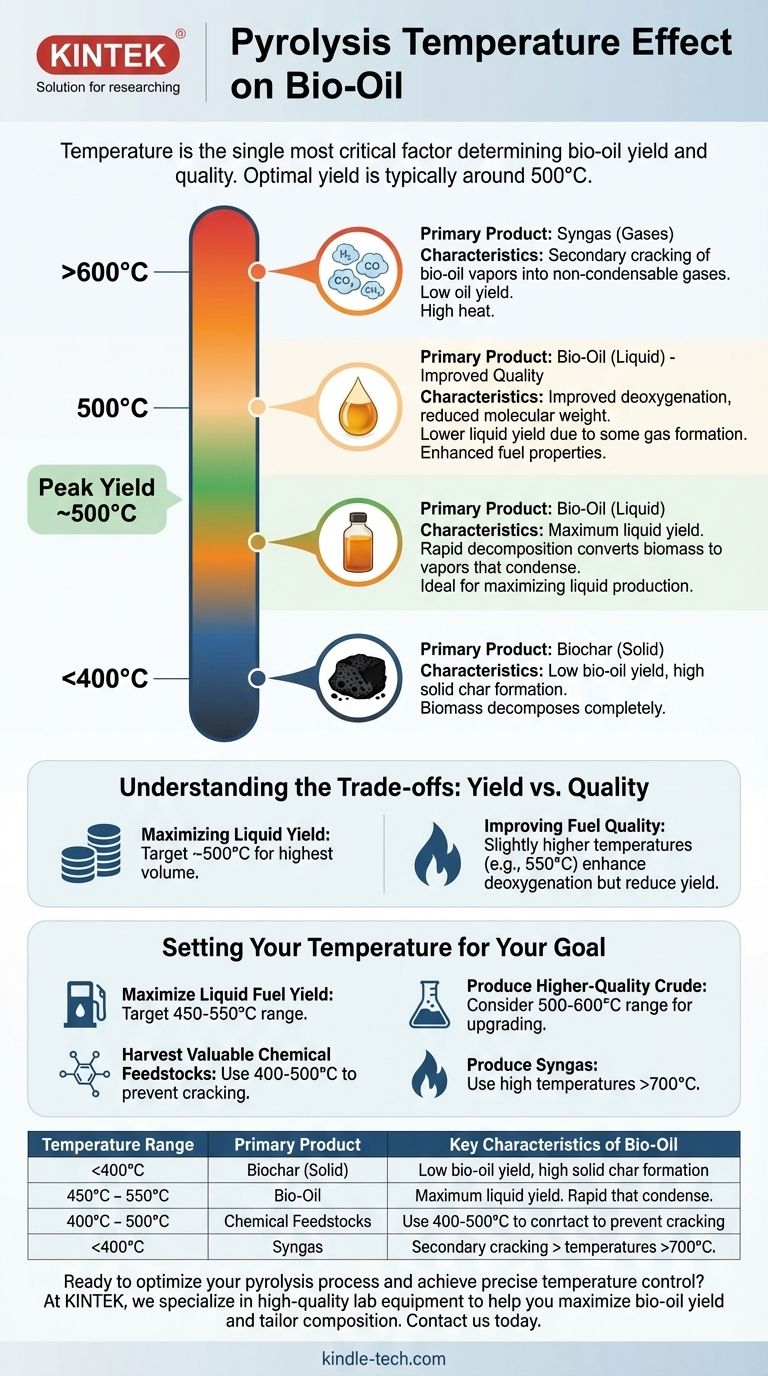

In short, pyrolysis temperature is the single most critical factor determining not only the amount of bio-oil produced but also its chemical composition and quality. As you increase the temperature from low to high, the primary product shifts from solid char to liquid bio-oil, and finally to non-condensable gases. The optimal temperature for maximizing bio-oil yield is typically around 500°C.

The central challenge is not finding a single "best" temperature, but understanding that temperature is a control lever. You must adjust it based on your primary goal, whether that is maximizing the liquid yield, improving fuel quality, or targeting specific chemical compounds.

How Temperature Governs Pyrolysis Products

Pyrolysis is the thermal decomposition of biomass in the absence of oxygen. Temperature directly controls the speed and nature of the chemical reactions that break down the biomass components (cellulose, hemicellulose, and lignin).

The "Sweet Spot" for Bio-Oil Yield

For fast pyrolysis, where the goal is to maximize liquid production, there is a well-defined optimal temperature range.

- Below 400°C: The reaction is too slow. Biomass decomposes incompletely, resulting in a high yield of solid biochar and a low yield of liquid bio-oil.

- Between 450°C and 550°C: This is the ideal range for maximizing bio-oil yield. A peak is often observed around 500°C, where rapid decomposition converts the majority of the biomass into vapors that can be condensed into liquid.

- Above 600°C: The bio-oil yield begins to decrease significantly. The high heat causes secondary cracking of the bio-oil vapors themselves, breaking them down into lighter, non-condensable gases (like H₂, CO, CO₂, and CH₄).

Impact on Bio-Oil Composition

Temperature doesn't just affect how much oil you get; it fundamentally changes what the oil is made of.

- Water Content: Higher temperatures promote dehydration reactions, which can increase the amount of water produced and captured in the final bio-oil.

- Acidity (pH): As temperature increases, the breakdown of hemicellulose and cellulose can produce more small organic acids, particularly acetic acid. This increases the overall acidity of the bio-oil, making it more corrosive.

- Oxygen Content: Higher temperatures tend to promote reactions that remove oxygen (deoxygenation). This is generally desirable as it increases the oil's energy density, but it comes at the cost of turning that oxygen into H₂O, CO, or CO₂, reducing liquid yield.

- Molecular Weight: Lower temperatures preserve larger, more complex molecules derived from lignin (like phenols). As temperatures rise, these heavy molecules are cracked into smaller, lighter compounds, reducing the oil's viscosity.

Understanding the Trade-offs: Yield vs. Quality

Optimizing pyrolysis temperature is a balancing act. What you gain in one area, you often lose in another. Understanding these trade-offs is key to process control.

Maximizing Liquid Yield

If your sole objective is to produce the highest possible volume of liquid from your biomass, your target is clear. You should operate at the temperature that minimizes char and gas formation, which is consistently found to be around 500°C.

Improving Fuel Quality

A "high-quality" fuel oil has low water content, low acidity, and a high heating value. Achieving this often requires moving slightly away from the maximum yield point.

Slightly higher temperatures (e.g., 550°C) can improve deoxygenation and reduce the average molecular weight, which can be beneficial for the oil's properties. However, this comes at the cost of losing some of your liquid yield to gas.

Targeting Specific Chemicals

If your goal is to produce valuable chemical feedstocks rather than fuel, your temperature strategy changes again. For example, to harvest valuable phenolic compounds from lignin, you would want to avoid the high temperatures that would crack them into less useful molecules. This often means operating at a lower temperature, sacrificing overall liquid yield to preserve the integrity of these target compounds.

Setting Your Temperature for Your Goal

Your choice of pyrolysis temperature should be a direct reflection of your desired outcome. There is no universally "correct" setting.

- If your primary focus is maximum liquid fuel yield: Target the 450-550°C range, with optimization tests centered around 500°C for your specific biomass.

- If your primary focus is producing a higher-quality crude for upgrading: Consider operating in the 500-600°C range to enhance deoxygenation, accepting a slight reduction in liquid yield.

- If your primary focus is harvesting valuable chemical feedstocks: Use lower temperatures (e.g., 400-500°C) to prevent the thermal cracking of your target molecules.

- If your primary focus is producing syngas: Intentionally use high temperatures (>700°C) to maximize the secondary cracking of vapors into non-condensable gases.

Ultimately, temperature is the most powerful tool you have to steer the pyrolysis process toward the products you value most.

Summary Table:

| Temperature Range | Primary Product | Key Characteristics of Bio-Oil |

|---|---|---|

| Below 400°C | Biochar (Solid) | Low yield, high char formation |

| 450°C - 550°C | Bio-Oil (Liquid) | Maximum liquid yield (peak ~500°C) |

| 500°C - 600°C | Bio-Oil (Liquid) | Improved deoxygenation, lower yield |

| Above 600°C | Syngas (Gases) | Secondary cracking, low oil yield |

Ready to optimize your pyrolysis process and achieve precise temperature control?

At KINTEK, we specialize in providing high-quality lab equipment, including precision pyrolysis reactors and furnaces, to help you maximize bio-oil yield and tailor composition for your specific research or production goals. Whether you're focused on fuel production, chemical feedstocks, or process development, our solutions deliver the reliability and control you need.

Contact us today to discuss your application and discover how our expertise can enhance your laboratory's capabilities. ➡️ Get in Touch

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing