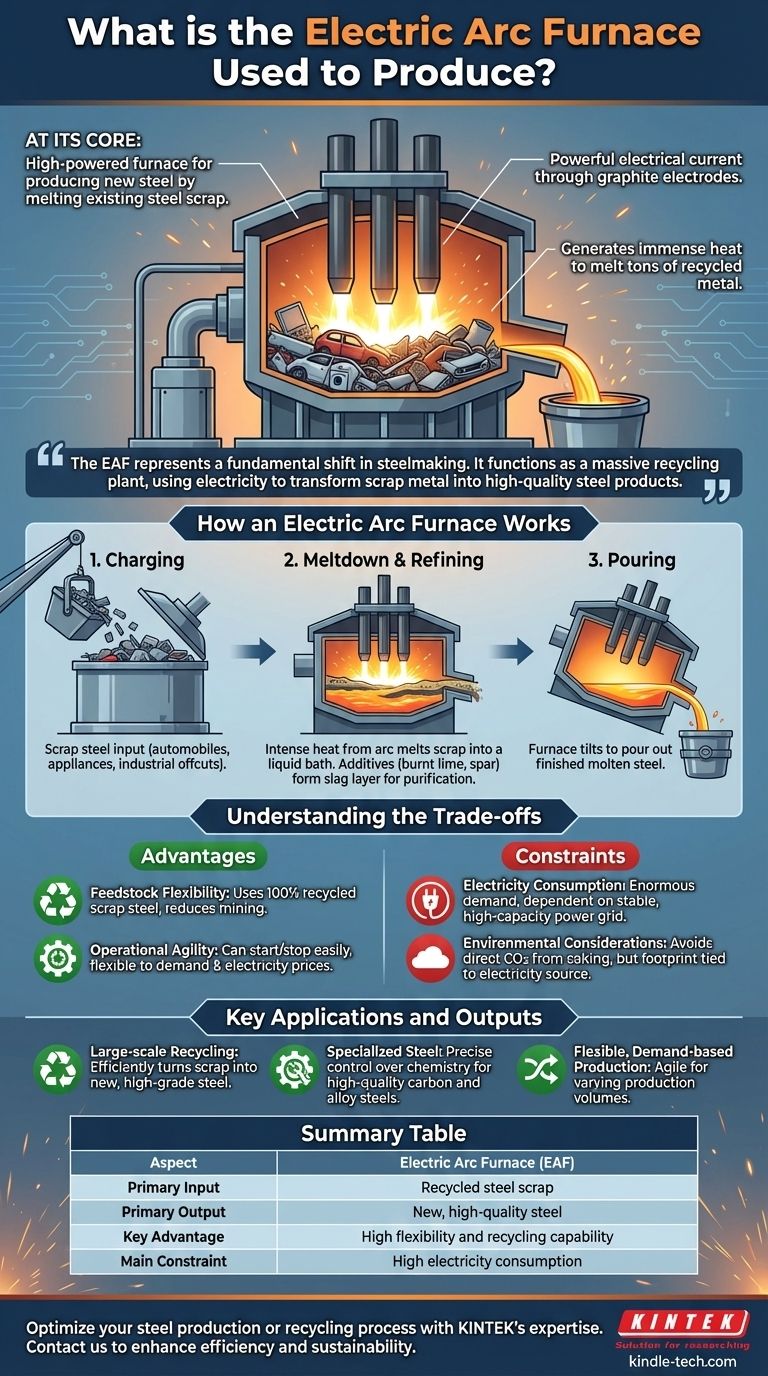

At its core, an electric arc furnace (EAF) is a high-powered furnace used almost exclusively to produce new steel by melting down existing steel scrap. It uses an incredibly powerful electrical current, passed through graphite electrodes, to generate an arc with enough heat to melt tons of recycled metal in a matter of hours.

The electric arc furnace represents a fundamental shift in steelmaking. Instead of creating steel from raw iron ore, it functions as a massive recycling plant, using electricity to transform scrap metal into high-quality steel products.

How an Electric Arc Furnace Works

An EAF does not burn fuel in the traditional sense. Its heat source is purely electrical, allowing for a controlled and intense melting process.

The Core Principle: Intense Heat from an Arc

The working principle involves lowering massive graphite electrodes into a furnace filled with scrap metal. A high-voltage current is passed through these electrodes, creating an electric arc—essentially a controlled lightning bolt—between the electrodes and the metal. This arc generates immense heat, reaching temperatures high enough to melt the scrap steel.

The Primary Input: Recycled Steel

The main "charge," or input material, for an EAF is steel scrap. This can range from shredded automobiles and appliances to industrial offcuts. This makes the EAF a cornerstone of the metal recycling industry.

The Process: From Solid to Liquid Steel

The operation follows a clear cycle:

- Charging: The removable roof of the furnace swings away, and large buckets dump scrap steel into the furnace shell.

- Meltdown: The roof is closed, the electrodes are lowered, and the powerful arc is initiated, melting the scrap into a liquid bath.

- Refining: Once the steel is molten, operators add materials like burnt lime and spar. These combine with impurities in the liquid steel to form a separate layer called slag, which can be skimmed off, purifying the final product.

Key Components of the Furnace

An EAF is a robust piece of industrial machinery. Its main components include a heavy steel shell lined with heat-resistant refractory material, a removable roof that holds the electrodes, and a hydraulic tilting system to pour out the finished molten steel.

Understanding the Trade-offs

While highly effective, the EAF method has distinct advantages and constraints compared to the traditional blast furnace, which makes steel from iron ore.

Advantage: Feedstock Flexibility

The EAF's greatest strength is its ability to use 100% recycled scrap steel. This reduces the need for mining new iron ore and coking coal, which are required for traditional blast furnaces.

Advantage: Operational Agility

EAFs can be started and stopped relatively easily. This provides significant flexibility, allowing steel mills to operate based on demand or electricity prices, whereas a traditional blast furnace must run continuously for years.

The Primary Constraint: Electricity Consumption

The main trade-off is an enormous demand for electricity. An EAF's operation is heavily dependent on the availability of a stable, high-capacity power grid, and energy costs are a major factor in its economic viability.

Environmental Considerations

EAFs avoid the direct CO2 emissions associated with burning coke to process iron ore. However, their overall environmental footprint is tied to the source of their electricity—if the power comes from fossil fuels, the carbon footprint is simply moved from the steel mill to the power plant.

Key Applications and Outputs

The EAF is not a one-size-fits-all solution; its use is tied to specific industrial goals.

- If your primary focus is large-scale recycling: The EAF is the most efficient technology available for turning scrap metal into new, high-grade steel.

- If your primary focus is producing specialized steel: The EAF offers precise control over the chemistry of the molten metal, making it ideal for producing high-quality carbon and alloy steels for demanding applications.

- If your primary focus is flexible, demand-based production: An EAF's ability to start and stop makes it far more agile than a traditional blast furnace, which is designed for continuous, high-volume output.

Ultimately, the electric arc furnace is the engine of modern steel recycling, enabling a more flexible and often more sustainable approach to steel production.

Summary Table:

| Aspect | Electric Arc Furnace (EAF) |

|---|---|

| Primary Input | Recycled steel scrap |

| Primary Output | New, high-quality steel |

| Key Advantage | High flexibility and recycling capability |

| Main Constraint | High electricity consumption |

Optimize your steel production or recycling process with KINTEK's expertise.

Whether you are involved in large-scale metal recycling, producing specialized alloy steels, or need flexible, demand-driven production capabilities, the right equipment is crucial. KINTEK specializes in providing robust and efficient lab and industrial equipment to support these advanced processes.

Contact us today to discuss how our solutions can enhance your steel production efficiency, improve product quality, and support your sustainability goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis