In certain ideal conditions, the energy efficiency of a rotary kiln can be exceptionally high. Specifically, electrically heated rotary kilns, which benefit from having no exhaust gas flow and minimal thermal leakage, can achieve an energy efficiency of over 95%. This figure, however, represents the upper limit and is highly dependent on the kiln's design and energy source.

The stated energy efficiency of a rotary kiln is not a single, universal value. It is a direct result of its heating method and engineering design. While electric kilns boast over 95% thermal efficiency, the overall operational effectiveness depends on matching the kiln's specific features to your material processing goals.

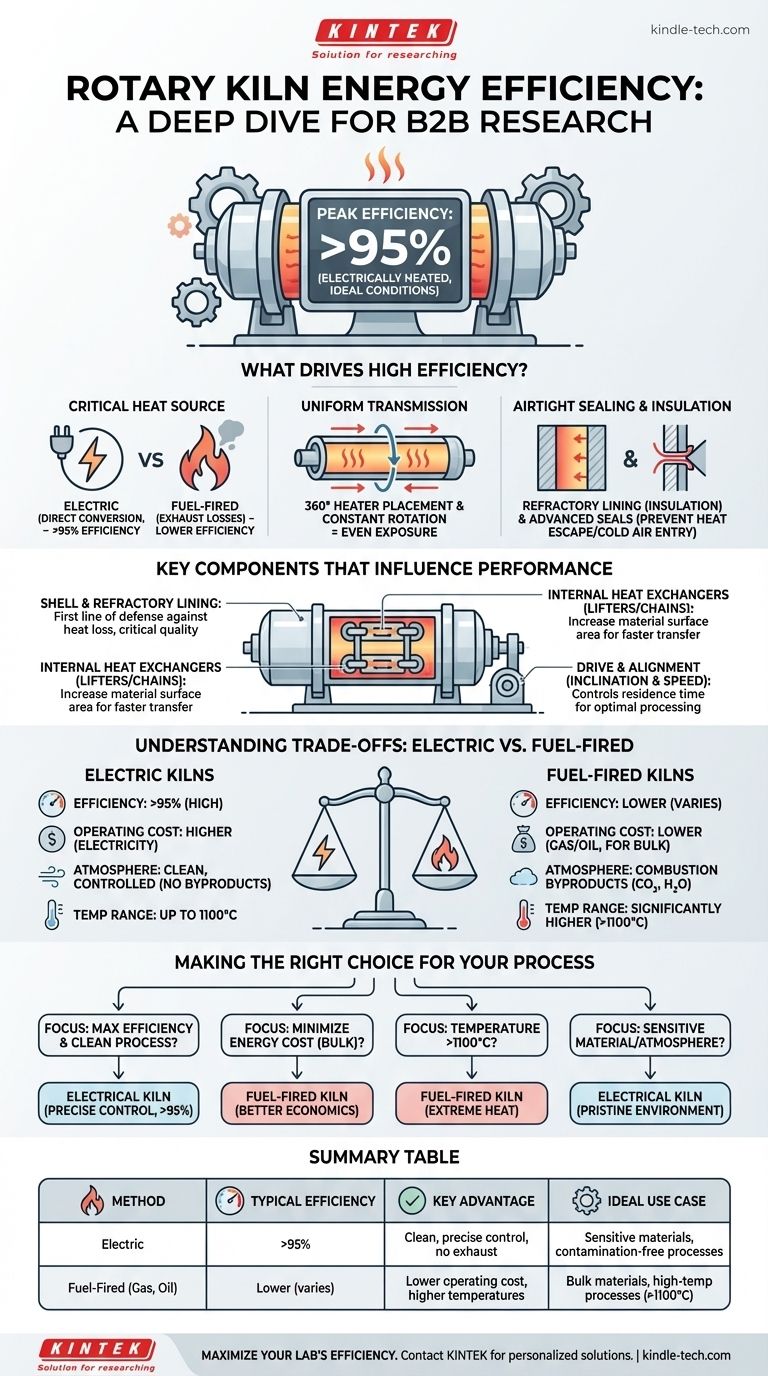

What Drives High Efficiency in a Rotary Kiln?

The efficiency of a rotary kiln is a function of how effectively it generates heat and transfers it to the material being processed. Several key design principles are responsible for minimizing energy waste.

The Critical Role of the Heat Source

The single largest factor in thermal efficiency is how the kiln is heated. Electrically heated kilns are inherently more efficient because energy is converted directly to heat inside the chamber with no need for combustion or exhaust.

In contrast, fuel-fired kilns (using gas, oil, or coal) lose a significant amount of energy through hot exhaust gases that must be vented from the system.

Uniform Heat Transmission

To be efficient, heat must be applied evenly to the material. High-efficiency designs feature 360° heater placement, surrounding the rotating tube to ensure uniform heat transfer from all directions.

The constant rotation of the kiln tumbles the material, ensuring the entire batch is consistently exposed to the heat source, which accelerates the process and prevents energy from being wasted on overheating specific spots.

Airtight Sealing and Insulation

Containing the heat is just as important as generating it. Rotary kilns are built with a heavy steel shell lined with a refractory material. This lining acts as a powerful insulator, minimizing the amount of heat that escapes through the kiln's body.

Furthermore, advanced seal measures at the feed and discharge ends prevent hot air from escaping and cold ambient air from entering, which would lower the internal temperature and force the system to consume more energy.

Key Components That Influence Performance

The mechanical construction of a rotary kiln is engineered to maximize its thermal performance and ensure the material is processed correctly.

Shell and Refractory Lining

The refractory lining is the kiln's first line of defense against heat loss. The quality, thickness, and composition of this material are critical for maintaining high internal temperatures without consuming excess energy.

Internal Heat Exchangers

Many kilns include internal structures like lifters or chains. These components are not passive; they are internal heat exchangers that pick up and shower the material through the hot atmosphere inside the kiln.

This action dramatically increases the surface area of the material exposed to heat, improving the rate and efficiency of heat transfer.

Drive and Alignment

The kiln's slight inclination and rotation speed are precisely calibrated. This ensures material moves through the kiln at a controlled pace, known as residence time.

Proper alignment, supported by components like riding rings and rollers, guarantees this smooth flow. If material moves too quickly, it isn't processed correctly; if it moves too slowly, energy is wasted.

Understanding the Trade-offs: Electric vs. Fuel-Fired

Choosing a kiln involves more than just looking at thermal efficiency ratings. The optimal choice depends on balancing efficiency with cost and specific process requirements.

Thermal Efficiency vs. Operating Cost

While an electric kiln's >95% thermal efficiency is impressive, electricity is often a more expensive utility than natural gas. For large-scale industrial processes, a lower-efficiency fuel-fired kiln may result in a lower total operating cost per ton of product.

Process Atmosphere Control

Electric kilns provide a clean, highly controlled atmosphere with no combustion byproducts. This is essential for processing sensitive materials where contamination is a concern.

Fuel-fired kilns, by nature, have an atmosphere rich in CO₂, water vapor, and other gases. While problematic for some materials, this can be neutral or even beneficial for others, such as in certain chemical reactions.

Temperature Range

The materials used in construction dictate the maximum operating temperature. Electric kilns often use nickel-based alloys that can handle temperatures up to 1100°C.

For processes that require much higher temperatures, such as cement manufacturing or calcining certain minerals, direct fuel-fired kilns are often the only viable option as they can achieve significantly higher heat levels.

Making the Right Choice for Your Process

Selecting the right kiln requires aligning the technology with your specific operational and financial goals.

- If your primary focus is maximum thermal efficiency and a clean process: An electrically heated kiln is the definitive choice, delivering precise control and over 95% efficiency.

- If your primary focus is minimizing energy cost for a bulk material: A direct fuel-fired kiln may offer a more favorable economic profile, even with its lower thermal efficiency.

- If your process requires temperatures above 1100°C: A fuel-fired system is almost always necessary to reach the extreme heat required for applications like cement and certain ore processing.

- If your material is sensitive to contamination or requires a specific atmosphere: The pristine and controllable environment of an electric kiln is a significant advantage.

Ultimately, the most efficient rotary kiln is the one that is correctly engineered for your specific material and production goals.

Summary Table:

| Heating Method | Typical Efficiency | Key Advantage | Ideal Use Case |

|---|---|---|---|

| Electric | >95% | Clean, precise control, no exhaust | Sensitive materials, contamination-free processes |

| Fuel-Fired (Gas, Oil) | Lower (varies) | Lower operating cost, higher temperatures | Bulk materials, high-temp processes (>1100°C) |

Maximize your lab's efficiency with the right rotary kiln solution. KINTEK specializes in high-performance lab equipment, including electric and fuel-fired rotary kilns tailored to your material processing needs. Whether you require the pristine environment of an electric kiln for sensitive materials or the high-temperature capabilities of a fuel-fired system, our experts will help you select the optimal design for maximum energy efficiency and cost-effectiveness. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals