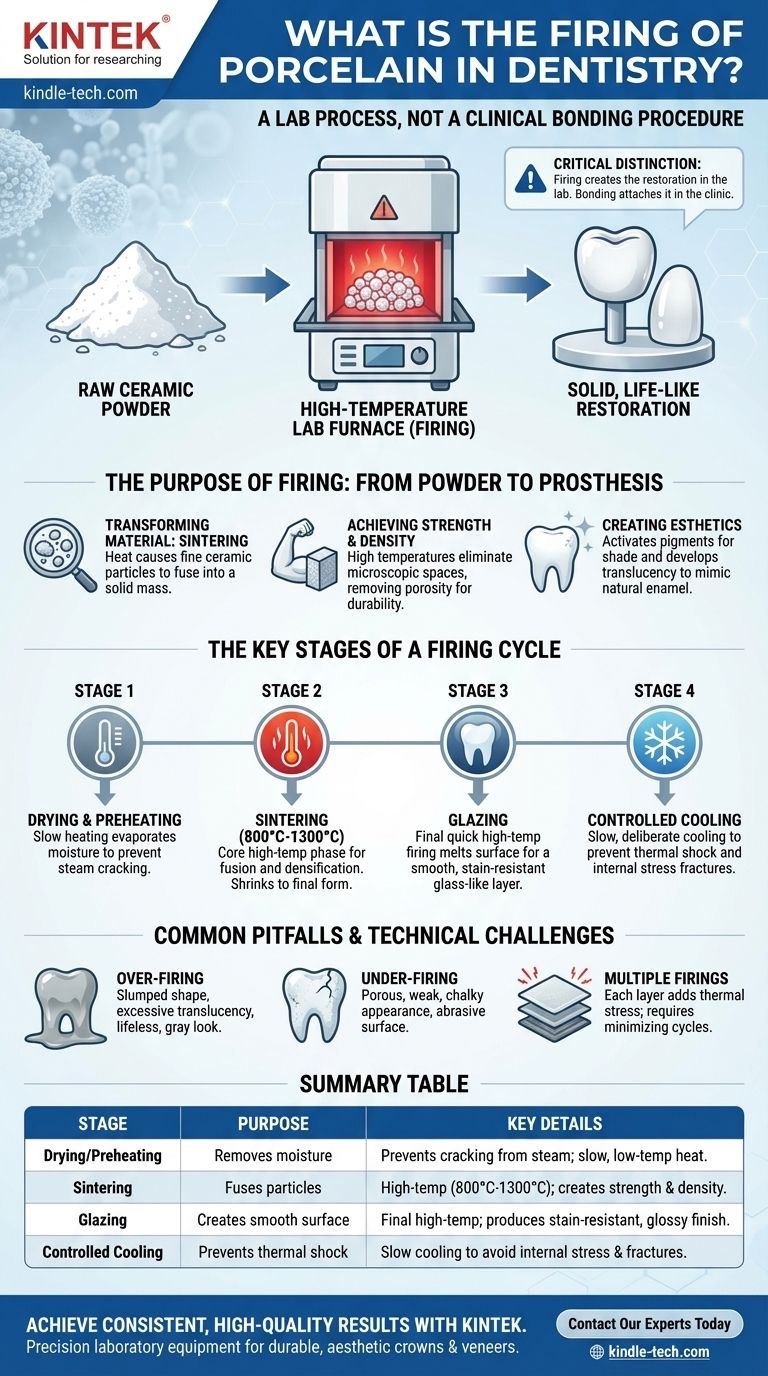

In dental technology, the firing of porcelain is a high-temperature laboratory process that transforms raw ceramic powder into a solid, strong, and life-like dental restoration, such as a crown or veneer. This crucial step happens in a specialized furnace long before the restoration is placed in a patient's mouth. It is not a clinical procedure for bonding the restoration to the tooth.

The critical distinction to understand is that porcelain firing occurs within a dental laboratory furnace to create the restoration. The separate process of attaching the finished restoration to the tooth in the dental clinic is called bonding or cementation.

The Purpose of Firing: From Powder to Prosthesis

The firing cycle is where a dental restoration acquires all of its essential properties. It is a carefully controlled process that fundamentally changes the material from a fragile powder into a durable and esthetic final product.

Transforming the Raw Material

Dental porcelain begins as a mixture of fine ceramic particles. During firing, heat causes these individual particles to fuse together in a process called sintering. This transforms the loose powder into a single, solid mass.

Achieving Strength and Density

The high temperatures eliminate the microscopic spaces between the porcelain particles. This densification process removes porosity, creating a much stronger structure that can withstand the significant forces of chewing.

Creating Life-like Esthetics

Firing is essential for developing the final appearance of the restoration. The heat activates the pigments within the porcelain to create the correct tooth shade and develops the material's translucency, allowing it to mimic the appearance of natural enamel.

The Key Stages of a Firing Cycle

A technician cannot simply place porcelain in a hot oven. The temperature must be raised and lowered through a precise, multi-stage cycle to prevent stress, cracking, and to achieve the desired clinical properties.

Drying and Preheating

The cycle begins with a slow, low-temperature heating phase. This is critical for evaporating any moisture from the built-up porcelain. Heating too quickly at this stage would cause the water to turn to steam, cracking the restoration from the inside.

Sintering (The High-Temperature Firing)

This is the core of the process where the furnace rapidly climbs to its peak temperature, often between 800°C and 1300°C (1472°F and 2372°F), depending on the specific type of porcelain. It is during this stage that the particles fuse, and the material shrinks to its final, dense form.

Glazing

After the initial sintering firings are complete, a final, quick firing at a high temperature is often performed. This glaze firing melts the outermost surface of the porcelain, creating a smooth, glass-like layer that is stain-resistant and kind to opposing teeth.

Controlled Cooling

Just as important as the heating is the cooling. The restoration must be cooled slowly and deliberately to prevent thermal shock. Cooling too rapidly introduces internal stresses that can lead to catastrophic fractures later on.

Common Pitfalls and Technical Challenges

Achieving a perfect result is a balance of science and artistry. Minor deviations in the firing process can have a major impact on the final restoration.

The Risk of Over-firing

If the porcelain is heated to too high a temperature or for too long, it can begin to slump and lose its carefully sculpted anatomical shape. Over-firing also results in excessive translucency, making the restoration look grey and lifeless.

The Problem of Under-firing

Insufficient heat or time results in incomplete sintering. An under-fired restoration will be porous, weak, and chalky in appearance. Its abrasive surface can also cause significant wear on the natural teeth it bites against.

The Challenge of Multiple Firings

Complex restorations are built with multiple layers of different porcelain shades to replicate a natural tooth. Each layer requires its own firing cycle. However, every trip to the furnace introduces more thermal stress, so technicians must achieve the desired result in the fewest cycles possible.

Making the Right Choice for Your Goal

Understanding the fundamentals of porcelain firing allows for better communication and appreciation of the final clinical result.

- If you are a dental patient: Understand that the quality of your crown or veneer is highly dependent on the skill and precision of the dental laboratory technician who performs the firing process.

- If you are a dental practitioner: Recognize that clear communication with your laboratory, especially regarding shades and material choice, is essential for the technician to execute the firing cycles correctly for an optimal result.

- If you are a dental technician: Prioritize meticulous furnace calibration and strict adherence to the manufacturer's firing parameters for each specific porcelain system to ensure predictable, high-quality outcomes.

Ultimately, the precise control of heat during the firing cycle is what transforms a simple ceramic powder into a durable and esthetic dental masterpiece.

Summary Table:

| Stage | Purpose | Key Details |

|---|---|---|

| Drying/Preheating | Removes moisture | Prevents cracking from steam; slow, low-temperature heat. |

| Sintering | Fuses particles | High-temperature firing (800°C-1300°C); creates strength and density. |

| Glazing | Creates smooth surface | Final high-temperature firing; produces stain-resistant, glossy finish. |

| Controlled Cooling | Prevents thermal shock | Slow cooling to avoid internal stress and fractures. |

Achieve consistent, high-quality results in your dental lab. The precision of the porcelain firing process is paramount to creating durable and aesthetically perfect crowns and veneers. KINTEK specializes in the lab equipment and consumables that dental technicians rely on for precise temperature control and reliable performance.

Let us help you enhance your laboratory's capabilities. Contact our experts today to find the perfect furnace and consumables for your specific porcelain systems and workflow needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow

- What is the temperature of a dental furnace? Mastering Heat for Perfect Zirconia Sintering

- Is ceramic the same as porcelain teeth? A Guide to Choosing the Right Dental Material

- Why is ceramic used in dentistry? For Aesthetic, Biocompatible, and Durable Restorations

- What type of zirconia has better esthetics? Choose High-Translucency 4Y/5Y Zirconia for Superior Beauty

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the sintering temperature of dental zirconia? Achieve Maximum Strength & Aesthetics

- What is a burnout oven? A Precision Tool for Flawless Investment Casting