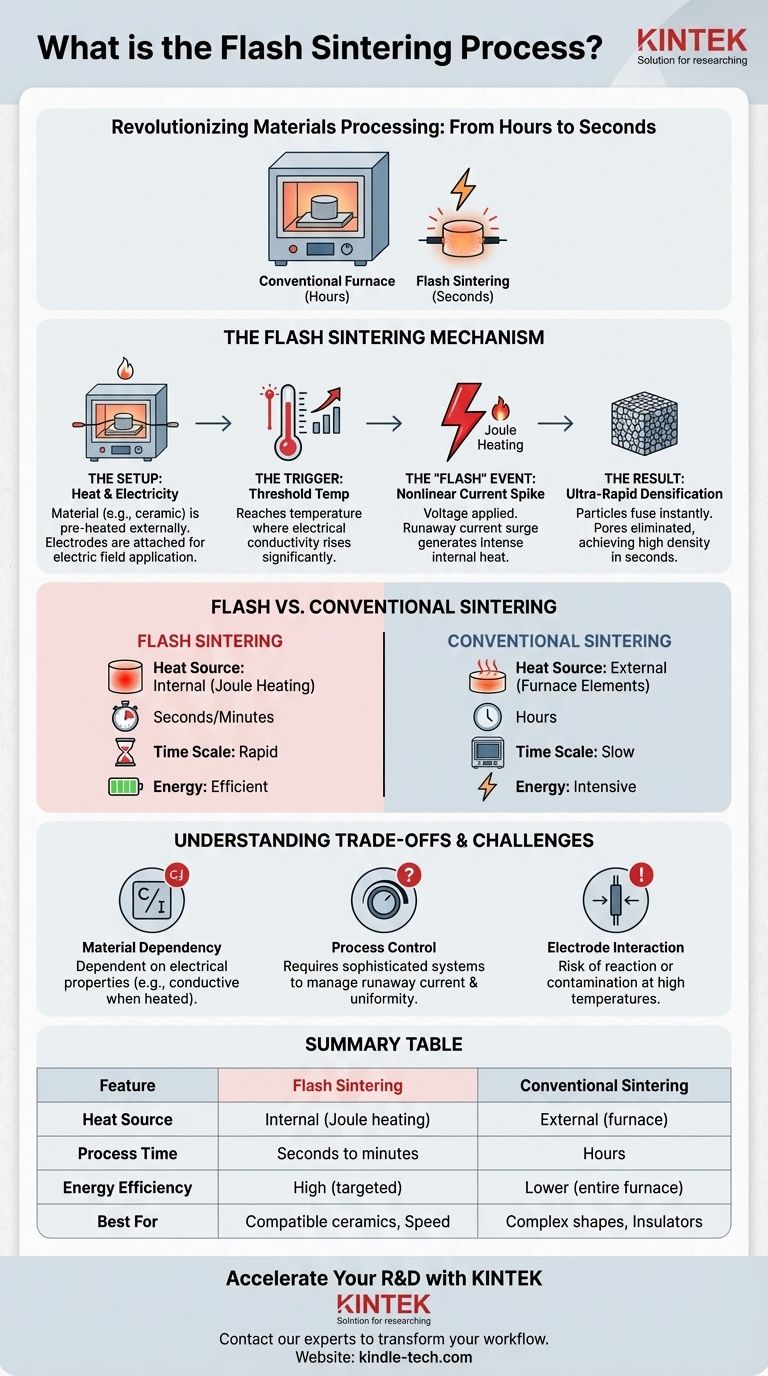

At its core, flash sintering is a revolutionary materials processing technique that uses an electric field to dramatically accelerate densification. While a conventional furnace heats a material over hours, flash sintering accomplishes the same goal in mere seconds. It works by pre-heating a material to a specific threshold temperature and then applying a voltage, which triggers a sudden surge of electrical current through the sample. This intense current generates internal Joule heating, rapidly fusing the material's particles together.

The fundamental difference between flash and conventional sintering is the method of energy delivery. Traditional methods rely on slow, external heating from a furnace, while flash sintering uses an electric field to generate rapid, internal heating directly within the material itself.

The Flash Sintering Mechanism Explained

To understand the power of this technique, it's essential to break down the distinct stages of the process, which set it apart from all conventional methods.

The Setup: Heat and Electricity

The material, often a ceramic, is placed in a furnace just like in a traditional process. However, two electrodes are also attached to the sample to allow an electric field to be applied across it.

The Trigger: Reaching the Threshold Temperature

The furnace begins to heat the material using conventional, external heat. This initial heating is not for densification; its purpose is to bring the material to a critical temperature where its electrical conductivity begins to increase significantly.

The "Flash" Event: A Nonlinear Current Spike

Once the threshold temperature is reached, a controlled voltage is applied. Because the material is now more electrically conductive, a current begins to flow. This creates a feedback loop: the current generates internal heat (Joule heating), which further increases conductivity, which in turn draws more current. The result is a nonlinear, runaway surge of electricity in a "flash" event.

The Result: Ultra-Rapid Densification

This massive and instantaneous burst of internal energy forces the particles within the material to fuse and consolidate. The pores between particles are eliminated, and the material achieves high density in a matter of seconds.

How Flash Sintering Differs from Conventional Methods

The distinction between flash sintering and traditional techniques like vacuum or pressure sintering lies in the speed, energy source, and efficiency of the process.

Heat Source: Internal vs. External

Conventional sintering is like a convection oven; it relies entirely on external heat from furnace elements slowly soaking into the material. Flash sintering uses the furnace as a "primer" before initiating its own powerful, internal heating via the electrical current.

Time Scale: Seconds vs. Hours

The slow transfer of external heat means traditional sintering cycles often last for many hours. By generating heat directly inside the material, flash sintering collapses this timeline, with the densification event itself often lasting less than a minute.

Energy Consumption: Efficiency vs. Waste

Heating a large furnace for hours is inherently energy-intensive. Flash sintering's ultra-short duration and targeted energy delivery lead to a dramatic reduction in overall energy consumption for the same result.

Understanding the Trade-offs and Challenges

While revolutionary, flash sintering is not a universal solution. Its unique mechanism presents specific challenges that are critical to understand.

Material Dependency

The process is fundamentally dependent on the material's electrical properties. It is most effective for materials (primarily ceramics) that are electrical insulators at room temperature but become sufficiently conductive when heated.

Process Control and Uniformity

Managing the runaway current spike requires highly responsive power supplies and sophisticated control systems to prevent thermal runaway, which can damage or destroy the sample. Achieving a uniform current density, and therefore uniform sintering, can be difficult in samples with complex shapes.

Electrode Interaction

Because electrodes are in direct physical contact with the sample at very high temperatures, there is a risk of chemical reactions or contamination. Careful selection of electrode material is crucial to maintaining the purity of the final product.

Making the Right Choice for Your Goal

Selecting a sintering method depends entirely on the material, the desired outcome, and production priorities.

- If your primary focus is maximum speed and energy efficiency: Flash sintering is the definitive choice for compatible materials, reducing processing time from hours to seconds.

- If you are working with large, complex shapes or electrically insulating materials: Conventional sintering provides more reliable and uniform heating, ensuring predictable results despite being much slower.

- If your primary focus is preventing any atmospheric contamination for ultra-pure components: Vacuum sintering remains the industry standard, as its core function is to create a tightly controlled, inert processing environment.

Ultimately, understanding the shift from slow external heating to rapid internal Joule heating is the key to leveraging the transformative potential of flash sintering.

Summary Table:

| Feature | Flash Sintering | Conventional Sintering |

|---|---|---|

| Heat Source | Internal (Joule heating) | External (furnace) |

| Process Time | Seconds to minutes | Hours |

| Energy Efficiency | High (targeted energy) | Lower (heats entire furnace) |

| Best For | Compatible ceramics requiring speed | Complex shapes, insulating materials |

Ready to accelerate your materials R&D and production?

Flash sintering's ability to reduce processing time from hours to seconds can dramatically increase your lab's throughput and slash energy costs. This technique is ideal for developing and manufacturing advanced ceramics and other compatible materials.

At KINTEK, we specialize in providing the advanced lab equipment and expert support you need to implement cutting-edge processes like flash sintering. Whether you're researching new materials or scaling up production, we have the solutions to help you succeed.

Contact our experts today to discuss how flash sintering technology can transform your workflow and meet your specific laboratory needs.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication