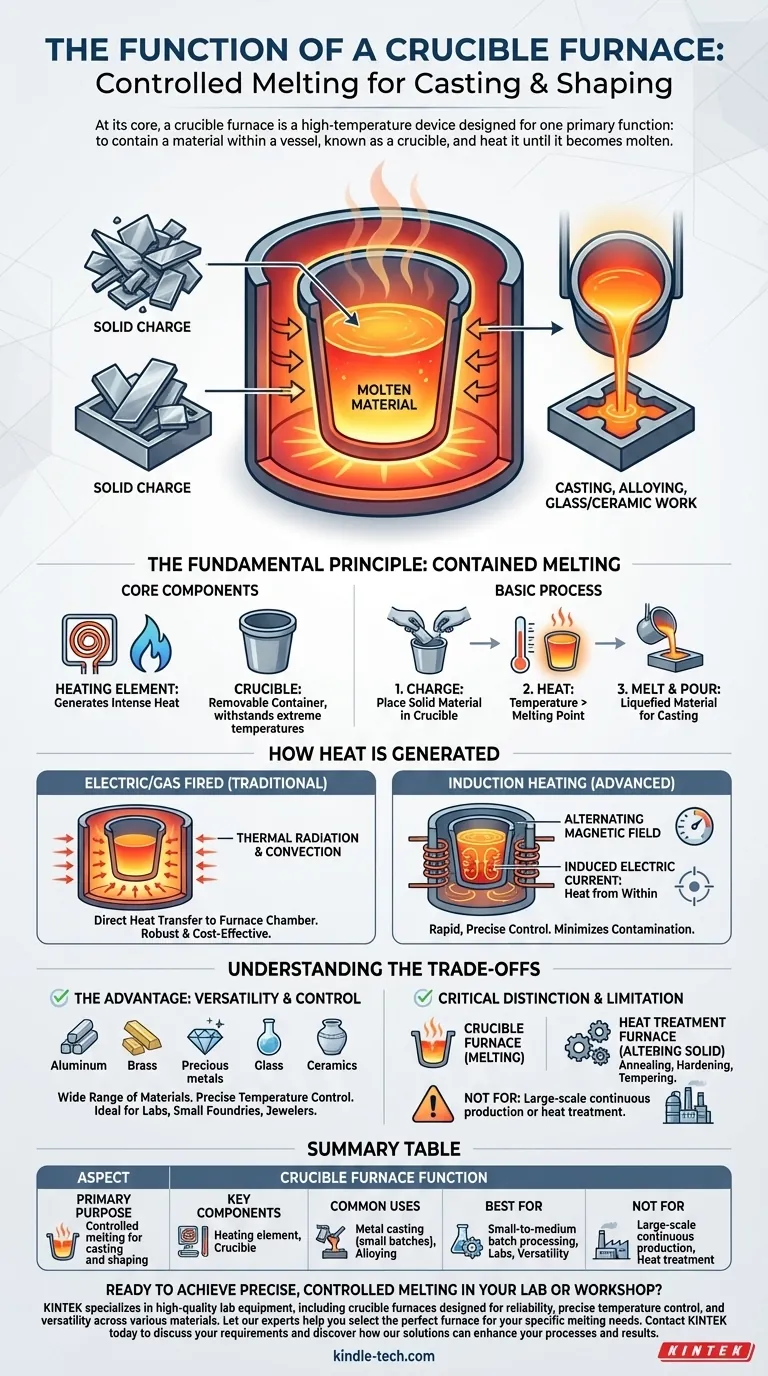

At its core, a crucible furnace is a high-temperature device designed for one primary function: to contain a material within a vessel, known as a crucible, and heat it until it becomes molten. This process is fundamental for applications requiring the liquid form of a substance, most commonly for casting metals, creating alloys, or working with materials like glass and ceramics.

The essential purpose of a crucible furnace is to perform controlled melting. While other furnaces alter solid materials through heat treatment, the crucible furnace's role is specifically to transform solids into a liquid state for pouring and shaping.

The Fundamental Principle: Contained Melting

The function of a crucible furnace is defined by its two key parts working in concert. Its design is elegantly simple and focused on achieving and maintaining a material's melting point.

The Core Components

A crucible furnace consists of a heating element and a crucible. The heating element, powered by electricity or gas, generates the intense heat required for melting.

The crucible is the removable container that holds the charge material. It is made from refractory materials like graphite, silicon carbide, or clay, which can withstand extreme temperatures without reacting with the substance being melted.

The Basic Process

The operation is straightforward. A solid material, such as metal scrap, ingots, or powder, is placed inside the crucible. The furnace is activated, and the heating element transfers thermal energy to the crucible and its contents.

The temperature is raised above the material's melting point and held there until the entire charge is liquefied. This molten material can then be poured into a mold to create a cast part.

How the Heat is Generated

While the goal is always melting, the method of generating heat can differ, which impacts the furnace's efficiency and application.

Electric Resistance or Gas Fired

The most common method involves electric resistance coils or gas burners that directly heat the furnace chamber. Heat is transferred to the crucible through a combination of thermal radiation and convection. This is a robust and cost-effective approach for many applications.

Induction Heating

A more advanced method is induction heating. In these furnaces, an electrical coil generates a powerful alternating magnetic field around the crucible.

This magnetic field induces a strong electric current directly within the conductive metal charge inside the crucible, causing it to heat up and melt rapidly from the inside out. This method offers excellent temperature control and minimizes contamination.

Understanding the Trade-offs

A crucible furnace is a versatile tool, but it is not a universal solution. Understanding its advantages and limitations is key to using it correctly.

The Advantage: Versatility and Control

Crucible furnaces are prized for their ability to melt a wide range of materials, from aluminum and brass to precious metals, glass, and ceramics. Their relatively compact size and precise temperature control make them ideal for laboratories, small foundries, jewelers, and artists.

The Critical Distinction: Melting vs. Heat Treatment

A common point of confusion is comparing a crucible furnace to a heat treatment furnace (like a vacuum furnace). A crucible furnace's function is melting a material for casting.

A heat treatment furnace, by contrast, is used to alter the physical and chemical properties of a solid material through controlled heating and cooling cycles, such as annealing (softening), quenching (hardening), or tempering. While some advanced furnaces can do both, their primary purposes are distinct.

The Limitation: Batch Size

Crucible furnaces are inherently batch-process tools and are generally used for small-to-medium volumes. They are not suited for the continuous, large-scale production seen in industrial operations that use equipment like blast furnaces.

Making the Right Choice for Your Goal

Selecting the right thermal equipment depends entirely on your intended outcome.

- If your primary focus is casting, alloying, or melting small batches: A standard gas or electric crucible furnace is your ideal tool due to its directness and simplicity.

- If your primary focus is altering the properties of solid metal parts (e.g., hardening a blade): You need a dedicated heat treatment furnace, not a crucible furnace.

- If your primary focus is high-purity melting with rapid, precise control: An induction crucible furnace is the superior choice for minimizing contamination and maximizing efficiency.

Ultimately, the function of a crucible furnace is to provide a controlled environment for turning solid into liquid.

Summary Table:

| Aspect | Crucible Furnace Function |

|---|---|

| Primary Purpose | Controlled melting of materials for casting and shaping |

| Key Components | Heating element (electric/gas/induction) and a removable crucible |

| Common Uses | Metal casting (jewelry, small foundries), alloying, glass/ceramic work |

| Best For | Small-to-medium batch processing, labs, and applications requiring versatility |

| Not For | Large-scale continuous production or heat treatment of solid parts (e.g., annealing) |

Ready to achieve precise, controlled melting in your lab or workshop?

Whether you're casting metals, creating alloys, or working with advanced materials, having the right equipment is crucial for success. KINTEK specializes in high-quality lab equipment, including crucible furnaces designed for reliability, precise temperature control, and versatility across various materials.

Let our experts help you select the perfect furnace for your specific melting needs. Contact KINTEL today to discuss your requirements and discover how our solutions can enhance your processes and results.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the difference between extruded and isostatic graphite? Choose the Right Material for Your Application

- What is a major advantage of pyrolysis in converting biomass to energy? It Creates Transportable Liquid Fuel

- What are the two types of sintering? Solid-State vs. Liquid-Phase Explained

- How is plastic waste different from other types of waste? The Hidden Threat of Microplastics

- What are the different types of pyrolysis units? Choose the Right Process for Your Biofuel or Biochar Goal

- Why is a high-precision constant temperature stirring reaction device necessary for functionalized BNNS grafting?

- What is the primary function of laboratory ovens in biomass moisture determination? Ensure Accurate Energy Calibration

- Why is an additional annealing process required following silicification? Ensure Composite Stability & Durability