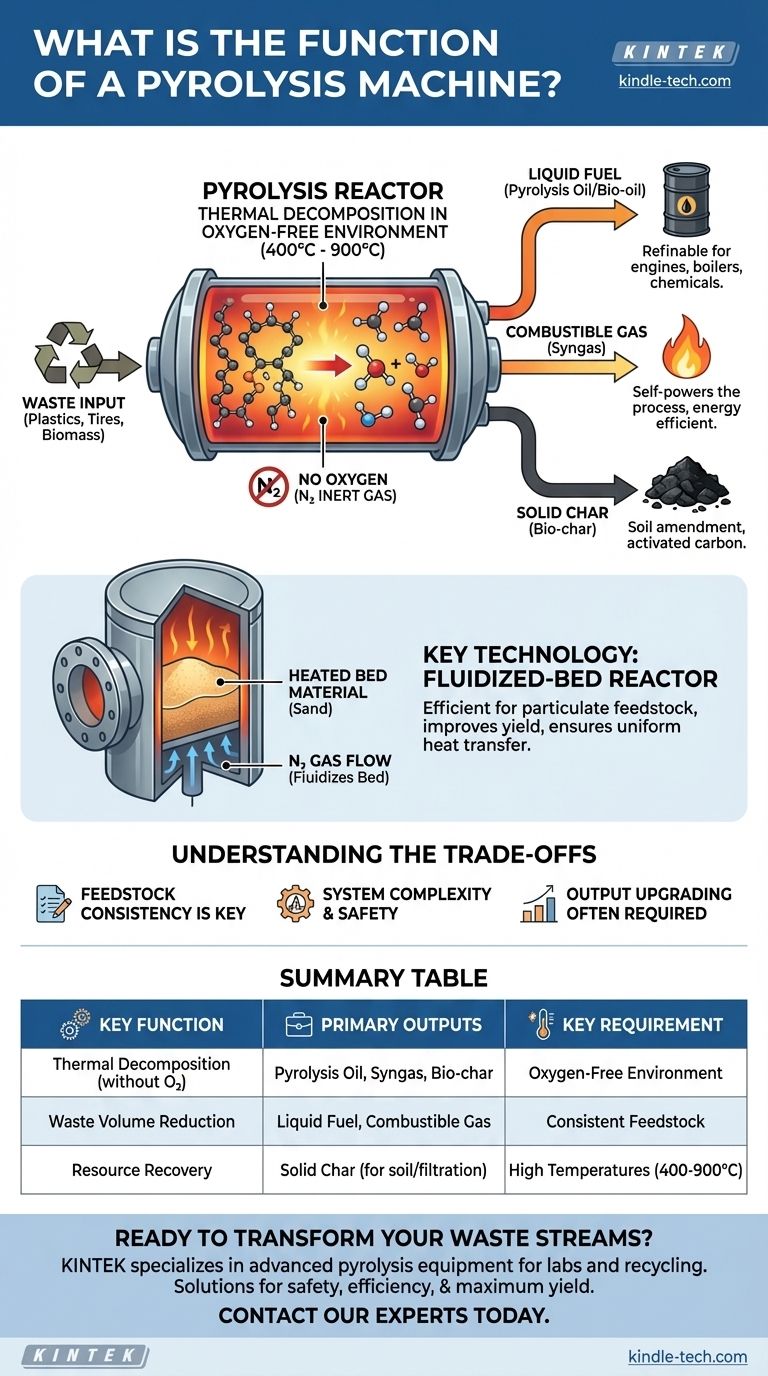

At its core, a pyrolysis machine's function is to thermally decompose materials like plastic, tires, or biomass in an oxygen-free environment. Instead of burning the material, this process uses extreme heat to break it down into its basic components, transforming low-value waste into valuable resources like liquid fuel, combustible gas, and a solid carbon-rich char.

A pyrolysis machine is not an incinerator; it is a chemical recycling and recovery unit. Its primary purpose is to convert complex organic waste streams into a set of distinct, usable products—pyrolysis oil, syngas, and bio-char—by applying high heat in the absence of oxygen.

How Pyrolysis Works: A Look Inside the Reactor

To understand the machine's function, you must first understand the core principles of the process it facilitates. It's a precise, controlled thermal reaction, not simple combustion.

The Core Principle: Thermal Decomposition

Pyrolysis means "fire-splitting" (from the Greek pyr and lysis). The machine feeds material into a sealed reactor and heats it to temperatures between 400°C and 900°C (750°F to 1650°F).

This intense heat breaks the complex, long-chain molecules of the feedstock into smaller, more stable molecules without them catching fire.

The Critical Element: An Oxygen-Free Environment

The absence of oxygen is the single most important factor that distinguishes pyrolysis from incineration. The machine creates an inert (non-reactive) atmosphere, often by injecting a gas like nitrogen.

This prevents combustion and ensures the material decomposes into the desired outputs rather than burning into ash and flue gas.

From Waste to Valuable Resources: The Outputs

The primary function of a pyrolysis machine is to create value. The process separates the initial waste material into three distinct product streams.

Pyrolysis Oil (Bio-oil)

This is a liquid fuel, often compared to a crude oil. It is the condensed vapor that results from the decomposition process and can be refined for use in engines, boilers, or as a feedstock for producing other chemicals.

Syngas (Synthesis Gas)

This non-condensable gas is a mixture of hydrogen, carbon monoxide, and other hydrocarbons. It is a combustible fuel that is typically used to power the pyrolysis plant itself, making the process more energy-efficient and self-sustaining.

Bio-char (Solid Residue)

This stable, carbon-rich solid is what remains after the volatile components have been vaporized. Bio-char can be used as a high-quality soil amendment to improve fertility, or it can be further processed into activated carbon for use in filtration systems.

Key Technology: The Fluidized-Bed Reactor

While many reactor types exist, the fluidized-bed reactor is a common and highly efficient design that highlights the engineering behind the process.

Why Use a Fluidized Bed?

This design is particularly effective for particulate feedstocks like woody biomass. It significantly improves the yield of valuable byproducts like bio-oils and gases.

The Function of the Bed Material

The reactor contains a layer of inert material, such as sand. This sand is heated and acts as the heat transfer medium, ensuring that every particle of feedstock is heated rapidly and uniformly.

The Role of Nitrogen Gas

A gas, usually pure nitrogen, is pumped in from the bottom. It serves two critical functions: maintaining the oxygen-free atmosphere and "fluidizing" the sand and feedstock particles. This makes the mixture behave like a fluid, maximizing contact and heat transfer efficiency.

Understanding the Trade-offs

Pyrolysis is a powerful technology, but it is not a magic bullet. It requires a sophisticated understanding of its operational constraints to be deployed successfully.

Feedstock Consistency is Key

The composition and quality of the output products are directly dependent on the input material. A machine optimized for plastic waste will not perform optimally with biomass without significant adjustments. Consistent, clean feedstock is required for predictable results.

System Complexity and Safety

Pyrolysis plants are complex industrial systems that handle high temperatures and flammable products. They demand robust safety protocols, precise monitoring, and skilled operators to run efficiently and safely.

Output Upgrading is Often Required

The direct outputs—especially pyrolysis oil—are often "crude" products. They typically require further filtering, upgrading, or refining before they can be sold as a final commercial product or used in sensitive equipment.

Making the Right Choice for Your Goal

The "function" of a pyrolysis machine is best defined by the specific outcome you want to achieve.

- If your primary focus is waste volume reduction: Pyrolysis is highly effective, converting bulky solid waste into a smaller volume of solid char and more easily transportable liquids and gases.

- If your primary focus is energy generation: The technology is a direct pathway to creating liquid (bio-oil) and gaseous (syngas) fuels from non-traditional sources.

- If your primary focus is material recovery: The process is unmatched for producing bio-char, a valuable commodity for agriculture and manufacturing activated carbon.

By breaking materials down to their chemical building blocks, a pyrolysis machine functions as a powerful tool for turning environmental liabilities into economic assets.

Summary Table:

| Key Function | Primary Outputs | Key Requirement |

|---|---|---|

| Thermal Decomposition (without oxygen) | Pyrolysis Oil, Syngas, Bio-char | Oxygen-Free Environment |

| Waste Volume Reduction | Liquid Fuel, Combustible Gas | Consistent Feedstock |

| Resource Recovery | Solid Char (for soil/filtration) | High Temperatures (400-900°C) |

Ready to transform your waste streams into valuable resources? KINTEK specializes in advanced pyrolysis equipment and consumables, providing laboratories and recycling facilities with the technology to efficiently convert plastic, tire, or biomass waste into fuel, gas, and bio-char. Our solutions are designed for safety, efficiency, and maximum yield. Contact our experts today to discuss how our pyrolysis systems can meet your specific recovery and energy generation goals.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals