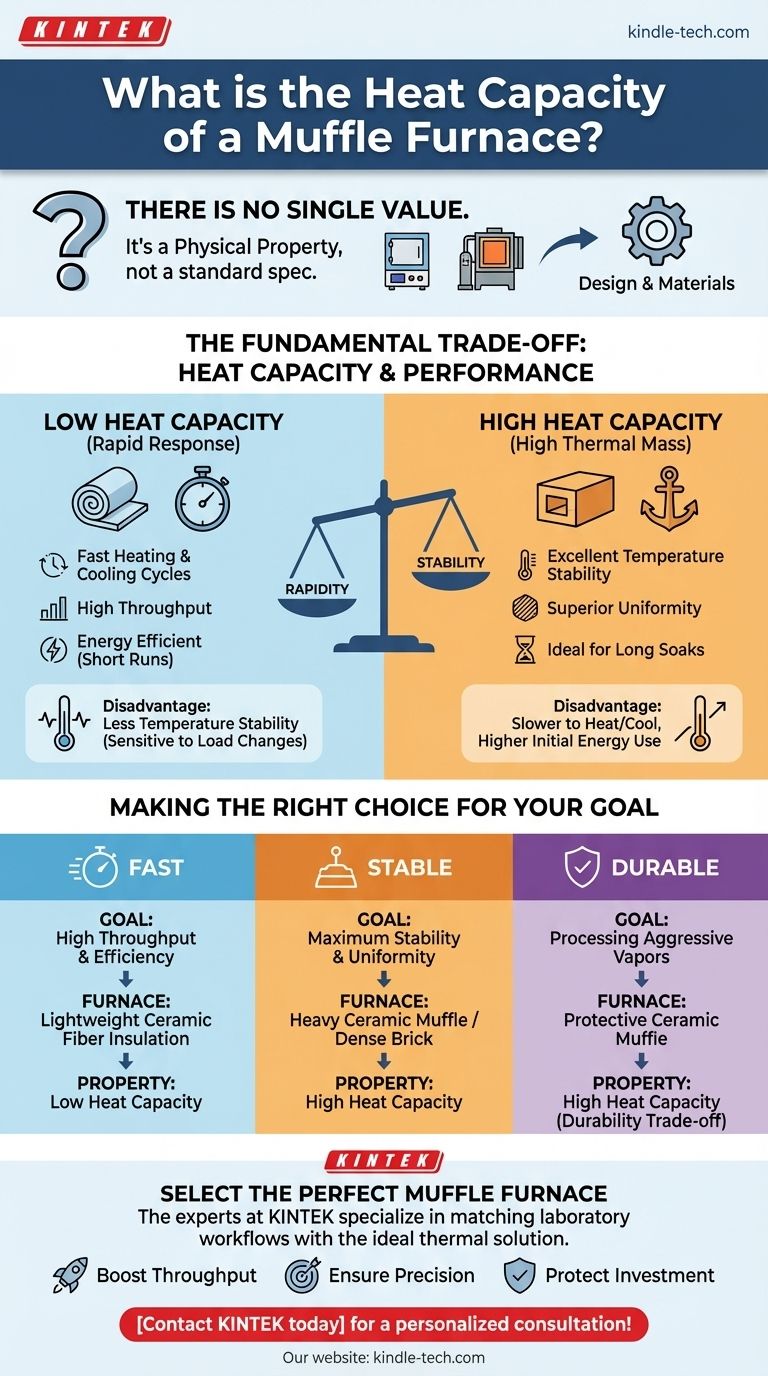

There is no single value for the heat capacity of a muffle furnace. The heat capacity is not a standardized specification but is instead a physical property determined by the specific mass, size, and materials used in the construction of an individual furnace. Therefore, a small laboratory furnace will have a vastly different heat capacity than a large, industrial production model.

A furnace's heat capacity is less a number to look up and more a consequence of its design. The critical insight is understanding the trade-off this creates: low heat capacity enables rapid heating and energy efficiency, while high heat capacity provides superior temperature stability.

What is Heat Capacity and Why Does It Matter?

Heat capacity is a fundamental concept in thermodynamics that directly impacts furnace performance. Understanding it helps you interpret why different furnaces behave the way they do.

Defining Heat Capacity

In simple terms, heat capacity is the amount of heat energy required to raise the temperature of an object by one degree (e.g., 1°C or 1°K).

An object with low heat capacity heats up and cools down quickly. An object with high heat capacity, often referred to as high thermal mass, requires much more energy to heat up and releases that energy slowly as it cools.

The Role of Mass and Materials

The heat capacity of a muffle furnace is the sum of the heat capacities of all its components: the internal chamber, the insulation, the steel housing, and the door.

Because these furnaces are built from various materials like stainless steel, ceramic fiber insulation, and dense embedded ceramic muffles, the final value is entirely dependent on the specific design and size of the unit. A larger, heavier furnace will always have a higher total heat capacity.

The Impact on Performance

This property directly governs two key performance metrics mentioned in furnace designs: heating/cooling rates and temperature uniformity. A furnace designed for "rapid high-temperature heating" is one engineered to have low overall heat capacity.

Key Factors Influencing a Furnace's Thermal Profile

The "heat capacity" you are sensing is a result of specific engineering choices. The most important factor is a furnace's insulation and chamber construction.

The Insulation Material

Modern muffle furnaces often use lightweight ceramic fiber insulation. This material has a very low heat capacity, which is a primary reason they can offer rapid heating and cooling cycles and are more energy-efficient.

Older furnaces, or those designed for extreme stability, may use dense refractory brick. This material has a very high heat capacity, making the furnace slow to heat but incredibly stable at its setpoint.

Chamber Construction

The design of the internal chamber is critical. Many furnaces feature an embedded ceramic muffle to protect the heating elements and resist aggressive gases.

This solid ceramic component has a significantly higher thermal mass than the surrounding insulation. A furnace with a heavy, dense muffle will heat more slowly but provide excellent temperature uniformity, as the muffle itself radiates heat evenly.

Understanding the Trade-offs

The choice between a low or high heat capacity design is a fundamental engineering trade-off. There is no single "best" option; the ideal choice depends entirely on the application.

High Heat Capacity (High Thermal Mass)

- Advantage: Excellent temperature stability. The high thermal mass resists temperature fluctuations, such as when the door is opened. This is ideal for processes requiring extremely uniform and stable heat.

- Disadvantage: Slower to reach the temperature setpoint and slower to cool down. This reduces throughput for labs that need to run many cycles per day. They also consume more initial energy to become fully heat-saturated.

Low Heat Capacity (Rapid Response)

- Advantage: Fast heating and cooling. This allows for more cycles to be completed in a workday and makes the furnace more energy-efficient for processes that don't require long soak times.

- Disadvantage: The chamber temperature can drop more significantly when a cold load is introduced or the door is opened. This requires sophisticated temperature controllers, like the solid-state relays mentioned in modern designs, to react quickly.

Making the Right Choice for Your Goal

Instead of seeking a specific heat capacity value, focus on how a furnace's thermal properties align with your primary objective.

- If your primary focus is high throughput and energy efficiency: Prioritize a furnace built with lightweight ceramic fiber insulation, which has a low heat capacity for rapid cycling.

- If your primary focus is maximum temperature stability and uniformity: Choose a furnace with a heavy ceramic muffle or dense refractory brick insulation, which provides high thermal mass.

- If your primary focus is processing with aggressive vapors: You will need a furnace with a protective, dense ceramic muffle, accepting the higher heat capacity as a necessary trade-off for durability.

Ultimately, understanding a furnace's thermal properties empowers you to select a tool that is truly fit for its purpose.

Summary Table:

| Design Goal | Recommended Furnace Type | Key Thermal Property |

|---|---|---|

| High Throughput & Energy Efficiency | Lightweight Ceramic Fiber Insulation | Low Heat Capacity (Rapid Heating/Cooling) |

| Maximum Temperature Stability | Heavy Ceramic Muffle / Dense Refractory Brick | High Heat Capacity (Superior Stability) |

| Processing Aggressive Vapors | Furnace with Protective Ceramic Muffle | High Heat Capacity (Durability Trade-off) |

Select the Perfect Muffle Furnace for Your Lab's Needs

Understanding the trade-offs between rapid heating and temperature stability is key to choosing the right equipment. The experts at KINTEK specialize in matching laboratory workflows with the ideal thermal solution. We provide high-quality muffle furnaces designed for specific applications, ensuring optimal performance, efficiency, and reliability.

Let us help you achieve your goals:

- Boost throughput with rapid-cycling furnaces.

- Ensure precision with stable, uniform heating.

- Protect your investment with durable designs for harsh processes.

Contact KINTEK today for a personalized consultation and find the muffle furnace that's perfectly fit for your purpose!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the body structure of a furnace? Unlocking the Dual-Layer Design for Superior Thermal Control

- How do you perform calcination? Master Precise Thermal Treatment for Your Materials

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- Does a muffle furnace need to be vented? Essential Safety and Performance Guide

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement