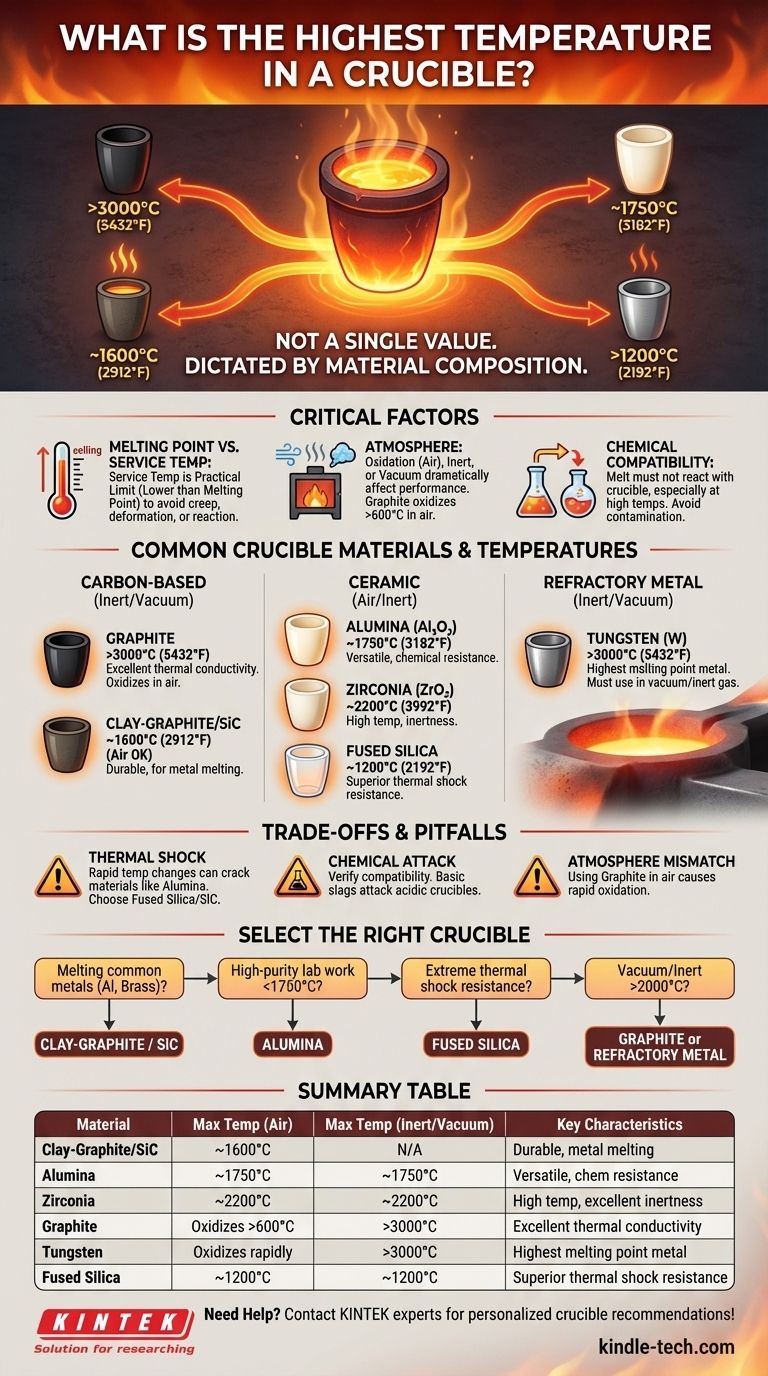

The maximum temperature a crucible can withstand is not a single value but is dictated entirely by its material composition. While a basic clay crucible may fail above 1300°C (2372°F), a crucible made from a refractory metal like tungsten can operate in an inert atmosphere at temperatures exceeding 3000°C (5432°F). The correct choice depends on the specific material being heated and the environment of the furnace.

The critical question is not "what is the highest temperature," but rather "which crucible material is required for my target temperature and application?" Choosing the right crucible means matching the material's properties—not just its melting point—to the specific heating process, chemical environment, and atmosphere.

Why Material Defines the Temperature Limit

Understanding the properties of crucible materials is essential for safe and effective high-temperature work. The melting point is only one part of the equation.

Melting Point vs. Service Temperature

A material's melting point is the absolute ceiling, but its maximum service temperature is the highest temperature at which it can be safely and repeatedly used without degrading. This practical limit is always lower than the melting point.

Operating too close to the melting point can cause the crucible to soften, deform under its own weight (a process known as creep), or react with its contents.

The Critical Role of Atmosphere

The atmosphere inside the furnace—whether it contains oxygen (oxidizing), is neutral (inert), or is a vacuum—dramatically affects a crucible's performance.

A graphite crucible, for example, has an exceptionally high melting point of over 3600°C. However, in the presence of air, it will begin to burn away (oxidize) and degrade rapidly at temperatures as low as 600°C.

Chemical Compatibility

The material you are heating must be chemically compatible with the crucible. At extreme temperatures, reactions that are negligible at room temperature can become aggressive, leading to contamination of your sample and the destruction of the crucible.

A Guide to Common Crucible Materials

Different materials are engineered for different temperature ranges and applications.

Carbon-Based Crucibles

- Graphite: Unmatched for high-temperature use in a vacuum or inert atmosphere (>3000°C). It has excellent thermal conductivity, promoting even heating. Its primary limitation is rapid oxidation in air.

- Clay-Graphite & Silicon Carbide (SiC): These are the workhorses for melting metals in foundries. They combine the heat transfer of graphite with the durability of a ceramic binder, typically operating up to 1600°C (2912°F) in air.

Ceramic Crucibles

- Alumina (Al₂O₃): A highly versatile and common choice for laboratory and industrial applications. It has good chemical resistance and a high service temperature of around 1750°C (3182°F).

- Zirconia (ZrO₂): Used when temperatures exceed the limits of alumina. Stabilized zirconia crucibles can be used up to 2200°C (3992°F) and offer excellent chemical inertness.

- Fused Silica (Quartz): While its maximum service temperature is lower, around 1200°C (2192°F), its defining feature is near-zero thermal expansion. This gives it phenomenal resistance to thermal shock (cracking from rapid temperature changes).

Refractory Metal Crucibles

- Tungsten (W): With the highest melting point of any metal (3422°C), tungsten is used for the most extreme temperature applications. Like graphite, it must be used in a vacuum or inert gas to prevent catastrophic oxidation.

- Molybdenum (Mo) & Tantalum (Ta): These metals also offer extremely high service temperatures (well above 2000°C) and are used for specialized high-vacuum furnace applications.

Understanding the Trade-offs and Pitfalls

Selecting a crucible involves balancing performance, cost, and operational constraints. Avoiding common mistakes is key to success and safety.

Thermal Shock Failure

Rapidly heating or cooling a crucible can cause it to crack. This is a major concern for materials like Alumina. If your process requires fast temperature cycles, a material like Fused Silica or Silicon Carbide is a much safer choice.

Chemical Attack

Never assume compatibility. For example, highly basic slags or molten alkali metals can aggressively attack acidic ceramic crucibles like Alumina or Fused Silica. Always verify that your melt will not dissolve your crucible.

Atmosphere Mismatch

The single most common failure mode for carbon-based crucibles is using them in the wrong atmosphere. Using a pure graphite crucible in an open-air induction furnace will result in the crucible quickly burning away.

Cost vs. Performance

There is a direct correlation between temperature performance and cost. An Alumina crucible is far less expensive than a Zirconia one, and a Tungsten crucible is in another category altogether. Over-specifying your crucible is an unnecessary expense.

How to Select the Right Crucible for Your Application

Choose the material that safely and economically meets the demands of your specific task.

- If you are melting common metals like aluminum, brass, or silver: A clay-graphite or silicon carbide crucible provides the best balance of cost, durability, and performance.

- If you are performing high-purity lab work or analysis below 1750°C: An alumina crucible is the standard choice for its purity and chemical resistance.

- If your process requires extreme resistance to thermal shock: A fused silica (quartz) crucible is the superior option, provided the temperature stays below 1200°C.

- If you are working in a vacuum or inert atmosphere above 2000°C: You must use high-purity graphite or a refractory metal like tungsten or molybdenum.

Matching the crucible material to your specific temperature, atmosphere, and contents is the fundamental principle of successful high-temperature work.

Summary Table:

| Material | Max Service Temperature (in Air) | Max Service Temperature (Inert/Vacuum) | Key Characteristics |

|---|---|---|---|

| Clay-Graphite / SiC | ~1600°C (2912°F) | N/A | Durable, good for metal melting |

| Alumina (Al₂O₃) | ~1750°C (3182°F) | ~1750°C (3182°F) | Versatile, good chemical resistance |

| Zirconia (ZrO₂) | ~2200°C (3992°F) | ~2200°C (3992°F) | High temp, excellent inertness |

| Graphite | Oxidizes above ~600°C | >3000°C (5432°F) | Excellent thermal conductivity |

| Tungsten (W) | Oxidizes rapidly | >3000°C (5432°F) | Highest melting point metal |

| Fused Silica | ~1200°C (2192°F) | ~1200°C (2192°F) | Superior thermal shock resistance |

Need Help Selecting the Perfect Crucible?

Choosing the wrong crucible can lead to failed experiments, contaminated samples, and costly equipment damage. KINTEK specializes in high-temperature lab equipment and consumables. Our experts will help you select the ideal crucible material—whether it's alumina, graphite, zirconia, or a refractory metal—based on your specific temperature, atmosphere, and chemical requirements.

We provide:

- Expert Guidance: Match your application to the perfect crucible material.

- High-Quality Products: Reliable crucibles for consistent, safe performance.

- Process Optimization: Ensure your high-temperature work is efficient and effective.

Don't risk your process—get it right from the start. Contact our technical specialists today for a personalized recommendation!

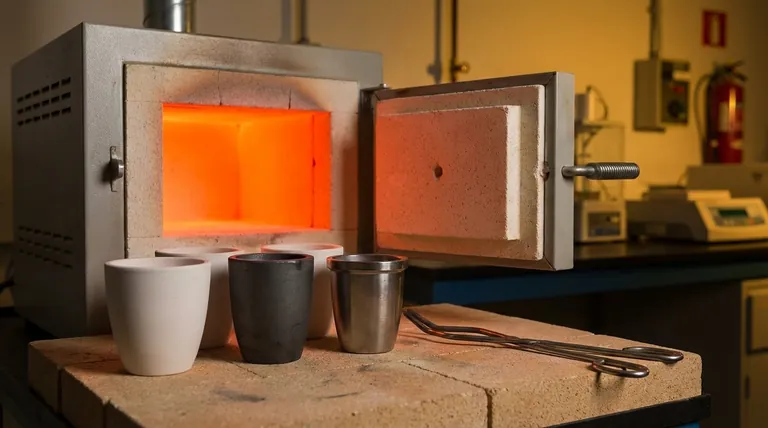

Visual Guide

Related Products

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What crucible is best for melting copper? Choose the Right Crucible for Clean, Efficient Melts

- How do MgO crucibles and sacrificial powders help LATP sintering? Ensure Purity and Prevent Adhesion

- What are the applications of a crucible furnace? Versatile Melting for Small Batches

- Why must aluminum alloys be heated in alumina crucibles? Ensure Pure Results in Molten Corrosion Experiments

- Why do crucibles not melt? The Science of Refractory Materials for High-Temperature Use

- How much heat can a ceramic crucible withstand? A Guide to Material-Specific Temperature Limits

- What are the disadvantages of a crucible furnace? Understanding Capacity, Cost, and Efficiency Limits

- What is the use of crucible furnace? Unlock Versatile Melting for Metals & Materials