In essence, a muffle furnace is a high-temperature oven used in laboratories and industrial settings for processes requiring extreme, uniform heat. Its defining feature is an internal chamber, the "muffle," made of high-temperature refractory materials. This chamber isolates the material being heated from the actual heating elements, preventing direct contact and contamination while ensuring precise temperature control, often exceeding 2000°C.

The core principle of a muffle furnace isn't just its ability to get hot, but its method of indirect heating. The internal "muffle" chamber acts as a barrier, ensuring that samples are heated uniformly by radiation and convection, free from any contaminants produced by the heating source itself.

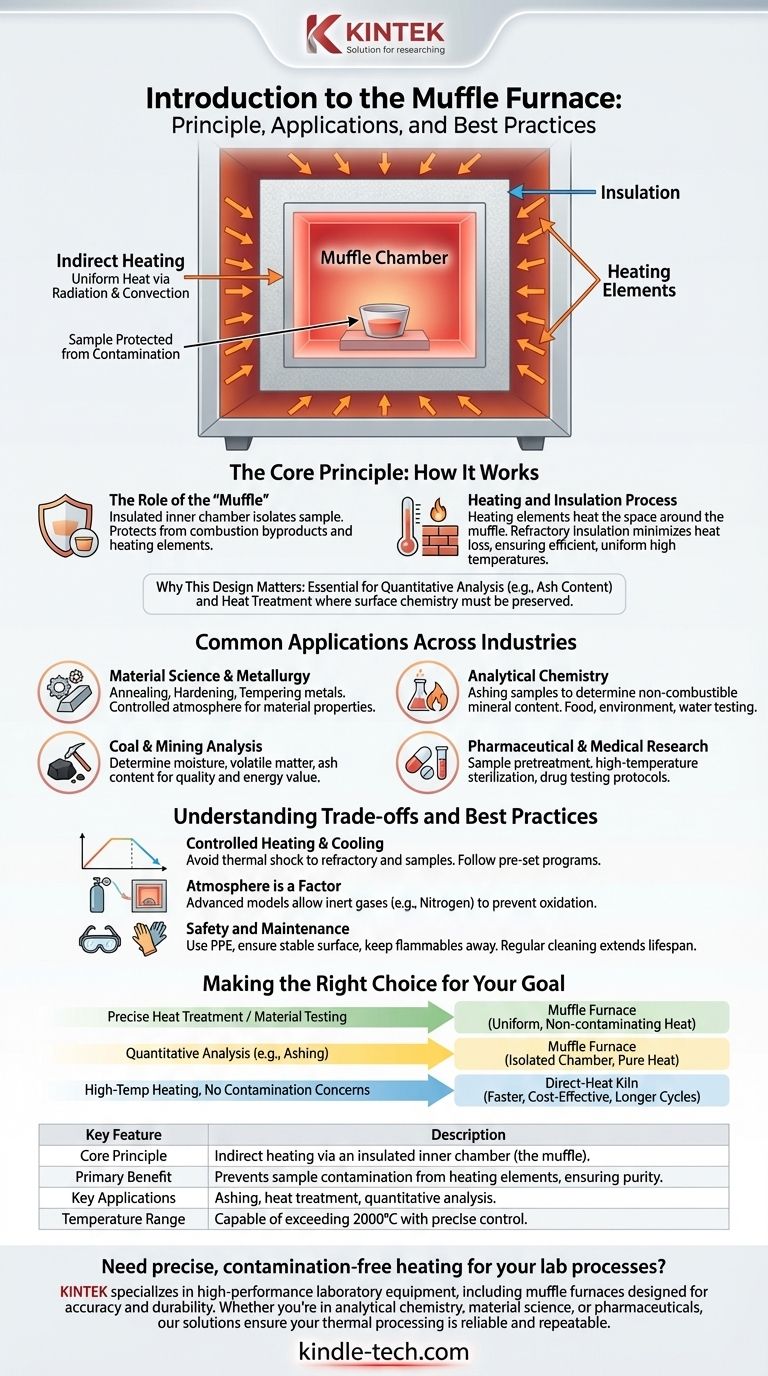

The Core Principle: How It Works

A muffle furnace's design is simple but highly effective. It revolves around creating a stable, clean, and evenly heated environment for thermally processing materials.

The Role of the "Muffle"

The term "muffle" refers to the insulated inner chamber that contains the sample. This chamber is the key differentiator from a simple furnace or kiln.

Its purpose is twofold: to protect the sample from the byproducts of combustion or direct radiation from the heating elements and to protect the heating elements from any fumes or splashes from the sample.

The Heating and Insulation Process

The furnace contains heating elements that heat the space around the muffle. The entire structure is lined with high-quality refractory bricks or ceramic fiber insulation.

This insulation minimizes heat loss and allows the chamber to reach and maintain extremely high temperatures efficiently. The heat radiates evenly into the muffle, ensuring the sample inside is heated from all sides at a consistent temperature.

Why This Design Matters

The indirect heating method provides critical advantages. It is essential for quantitative analysis, such as determining the ash content of a sample, where contamination would alter the results.

It is also vital for heat treatment of metals and other materials where the surface chemistry must not be altered by exposure to a direct flame or electrical element.

Common Applications Across Industries

The unique capabilities of the muffle furnace make it an indispensable tool in a wide range of fields.

Material Science and Metallurgy

In this field, furnaces are used for processes like annealing, hardening, and tempering metals. The controlled atmosphere and uniform temperature are critical for achieving desired material properties.

Analytical Chemistry

Laboratories use muffle furnaces for ashing samples, which is the process of burning off organic substances to determine the non-combustible mineral content. This is common in food science, environmental analysis, and water quality testing.

Coal and Mining Analysis

The furnace is used to determine key properties of coal, including its moisture content, volatile matter, and ash content. These are critical metrics for quality control and determining the energy value of the fuel.

Pharmaceutical and Medical Research

In medical and pharmaceutical labs, muffle furnaces are used for the pretreatment of samples and in certain drug testing protocols that require high-temperature sterilization or processing.

Understanding the Trade-offs and Best Practices

While powerful, operating a muffle furnace requires an understanding of its operational principles and limitations to ensure safety and accuracy.

Controlled Heating and Cooling is Critical

Materials, both the sample and the furnace lining itself, can be damaged by thermal shock. Therefore, furnaces must be heated and cooled according to a pre-set program.

Rapidly changing the temperature can cause cracking in the refractory materials or ruin the sample being processed.

Atmosphere is a Factor

Standard muffle furnaces operate with the air present in the chamber. However, some advanced models, like pass-through furnaces, allow for the introduction of inert gases like nitrogen.

This is crucial for processes where oxidation of the sample at high temperatures must be prevented.

Safety and Maintenance are Non-Negotiable

Due to the extreme temperatures, safety is paramount. This includes using personal protective equipment (PPE), ensuring the furnace is on a stable, heat-resistant surface, and keeping flammable materials far away.

Regular cleaning of the chamber and inspection of components extends the furnace's lifespan and guarantees consistent, accurate results.

Making the Right Choice for Your Goal

Selecting and using a muffle furnace depends entirely on the precision and environment your process requires.

- If your primary focus is precise heat treatment or material testing: The uniform, non-contaminating heat of a muffle furnace is essential for achieving repeatable results.

- If your primary focus is quantitative analysis (like ashing): The isolated chamber is non-negotiable, as it ensures that the only thing affecting the sample is pure, controlled heat.

- If your primary focus is simply high-temperature heating without contamination concerns: A simpler, direct-heat kiln might be a faster or more cost-effective option, as muffle furnaces often have longer heating and cooling cycles.

Understanding its principle of indirect heating is the key to leveraging its power for accurate and repeatable results in any laboratory or industrial setting.

Summary Table:

| Key Feature | Description |

|---|---|

| Core Principle | Indirect heating via an insulated inner chamber (the muffle). |

| Primary Benefit | Prevents sample contamination from heating elements, ensuring purity. |

| Key Applications | Ashing, heat treatment (annealing, tempering), quantitative analysis. |

| Temperature Range | Capable of exceeding 2000°C with precise control. |

Need precise, contamination-free heating for your lab processes?

KINTEK specializes in high-performance laboratory equipment, including muffle furnaces designed for accuracy and durability. Whether you're in analytical chemistry, material science, or pharmaceuticals, our solutions ensure your thermal processing is reliable and repeatable.

Contact our experts today to find the perfect muffle furnace for your specific application and enhance your lab's capabilities.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a sintering furnace? A Guide to High-Temperature Materials Processing

- How does a high-temperature box resistance furnace assist in PBF annealing? Optimize Stress Relief and Microstructure

- What role does a muffle furnace play in the thermal treatment and synthesis of Li2.5Y0.5Zr0.5Cl6? Master Your Synthesis

- What is dry ashing? A Reliable Method for Analyzing Inorganic Composition

- What are the primary functions of a laboratory high-temperature box furnace in heavy metal coolant interaction experiments?

- How efficient is electric resistance heating? Unveiling the Truth About 100% Efficiency and Real-World Costs

- What is the range of a muffle furnace? Choose the Right Temperature for Your Lab

- What is an electric muffle furnace? Achieve Unmatched Thermal Purity and Uniformity