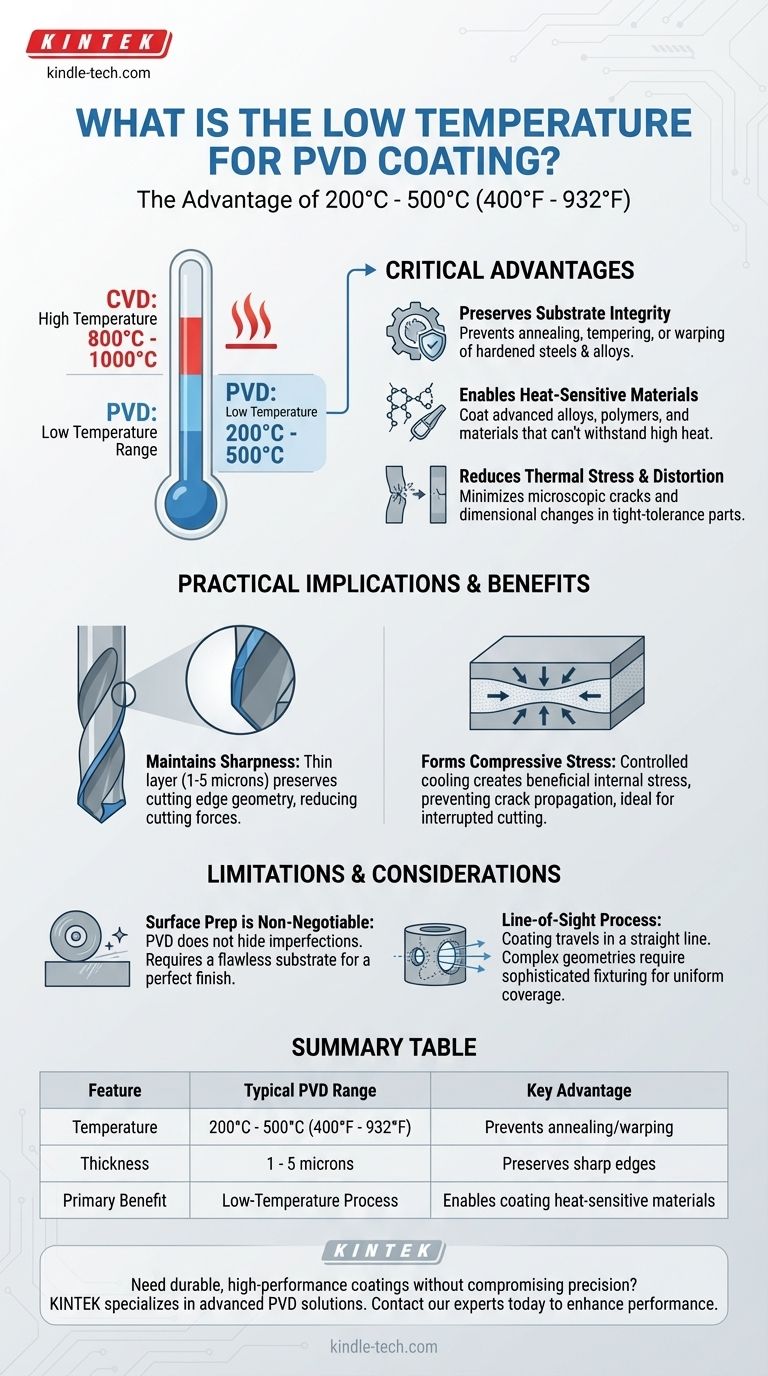

In the context of industrial coatings, Physical Vapor Deposition (PVD) is considered a low-temperature process. While temperatures can vary based on the specific material and desired outcome, PVD coatings are typically applied in a range of 200°C to 500°C (approximately 400°F to 932°F), with many processes operating around the upper end of that spectrum.

The term "low temperature" is relative, but its significance is absolute. The primary advantage of PVD's operating temperature is its ability to enhance a material's surface properties without causing thermal damage or altering the core characteristics of the underlying substrate.

Why "Low Temperature" Is a Critical Advantage

The defining benefit of the PVD process is not just the coating itself, but its ability to be applied without compromising the part it is meant to protect. This is a stark contrast to higher-temperature processes like Chemical Vapor Deposition (CVD), which can run upwards of 800°C - 1000°C.

Preserving Substrate Integrity

Many materials, particularly hardened steels and precision-engineered alloys, get their desirable properties from specific heat treatments.

Exposing these materials to excessive heat can anneal, temper, or warp them, effectively undoing their engineered benefits. PVD's lower temperature range operates safely below the critical thermal threshold for most of these substrates.

Enabling Coating on Heat-Sensitive Materials

The lower processing temperature opens the door to coating materials that would be destroyed by other methods.

This makes PVD suitable for certain alloys, and in some advanced applications, even polymers or other materials that cannot withstand high heat.

Reducing Thermal Stress and Distortion

Applying a coating at an extremely high temperature can induce significant stress in the part as it cools, leading to microscopic cracks or dimensional changes.

PVD minimizes this risk, which is especially important for components with tight geometric tolerances, such as cutting tools, molds, and medical implants.

Understanding the Practical Implications

The temperature of the PVD process directly influences its suitability for different applications and is a key reason for its widespread adoption.

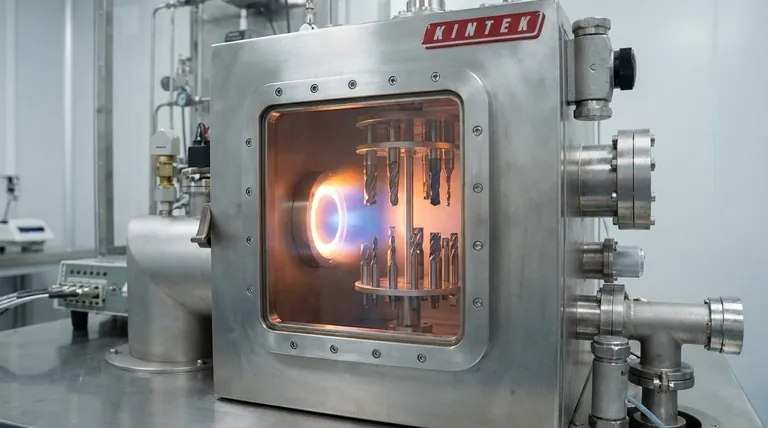

Maintaining the Sharpness of Cutting Edges

For cutting tools like drills, end mills, and saw blades, maintaining a perfectly sharp edge is paramount for performance.

The lower temperature and thin deposition layer (typically 1-5 microns) of PVD ensures that the cutting edge is not rounded or dulled during the coating process, preserving its sharpness and reducing cutting forces.

Forming Compressive Stress

During the PVD process, the controlled cooling can form beneficial compressive stress within the thin film.

This internal stress helps to prevent the formation and propagation of cracks, making PVD-coated tools exceptionally well-suited for interrupted cutting operations like milling, where the tool is constantly engaging and disengaging with the workpiece.

Limitations and Considerations

While powerful, the PVD process is not a universal solution. Its characteristics present certain trade-offs that must be understood for successful application.

Surface Preparation is Non-Negotiable

PVD is a thin-film process that perfectly replicates the underlying surface. It does not level, fill, or hide any scratches, machine marks, or other imperfections.

If you desire a polished P-VD finish, you must start with a mirror-polished substrate. A brushed finish requires a perfectly prepared brushed substrate. Any flaw in the base material will be visible through the coating.

It's a Line-of-Sight Process

In a PVD chamber, the coating material travels in a straight line from the source to the substrate.

Complex internal geometries or deep, narrow holes can be difficult to coat uniformly without sophisticated part rotation and fixturing. This must be accounted for when designing parts intended for PVD coating.

Making the Right Choice for Your Application

Selecting a coating process requires aligning its capabilities with your primary goal.

- If your primary focus is performance on heat-sensitive parts: PVD is the superior choice, as its low process temperature will not damage the substrate's temper or structural integrity.

- If your primary focus is a decorative finish: PVD offers a durable, uniform, and high-end finish, but remember that the final appearance is entirely dependent on the quality of the surface preparation beforehand.

- If your primary focus is extreme wear on high-heat components: While PVD offers excellent hardness and wear resistance, a higher-temperature CVD process might be considered if your substrate can tolerate the heat without compromise.

Ultimately, PVD's low-temperature nature is the key that unlocks high performance without high risk.

Summary Table:

| Feature | Typical PVD Coating Range | Key Advantage |

|---|---|---|

| Temperature | 200°C - 500°C (400°F - 932°F) | Prevents annealing/warping of substrates |

| Coating Thickness | 1 - 5 microns | Preserves sharp edges on cutting tools |

| Primary Benefit | Low-Temperature Process | Enables coating of heat-sensitive materials |

Need a durable, high-performance coating that won't compromise your precision parts? KINTEK specializes in advanced PVD coating solutions for cutting tools, molds, and medical components. Our low-temperature process ensures your substrates retain their hardness and dimensional accuracy. Contact our experts today to discuss how we can enhance your product's performance and longevity.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition