In DC magnetron sputtering, the magnetic field is the critical component that dramatically increases the efficiency and speed of the coating process. It works by creating a magnetic "trap" that confines electrons near the surface of the target material. This confinement intensifies the ionization of the inert gas (like argon), creating a much denser plasma that bombards the target more effectively and results in a significantly faster deposition rate onto the substrate.

The fundamental role of the magnetic field in magnetron sputtering is to trap electrons near the target surface. This creates a dense, localized plasma that significantly accelerates the rate at which target material is sputtered onto a substrate, all while operating at lower pressures and protecting the substrate from excess heat.

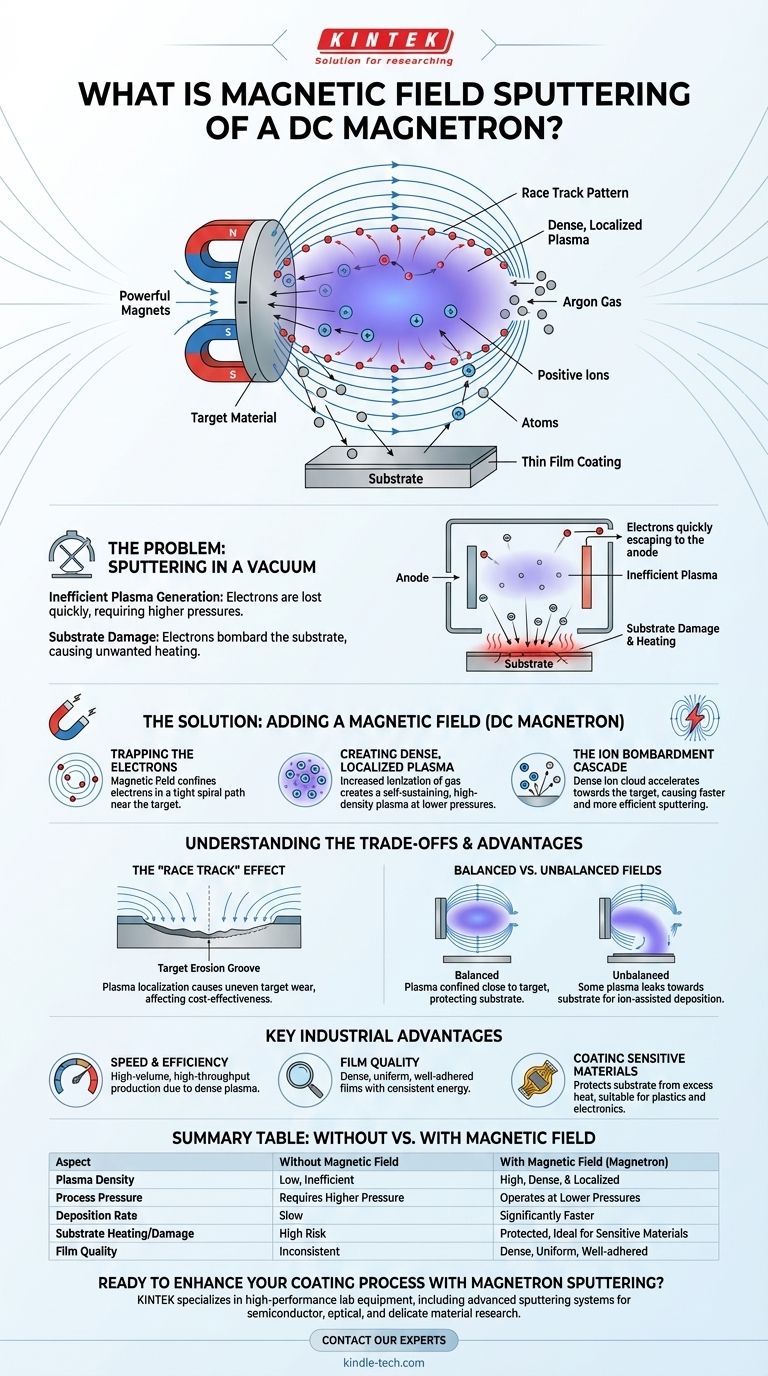

The Problem With Sputtering in a Vacuum

To understand the genius of the magnetic field, we must first look at the process without it. Standard DC sputtering involves creating a plasma in a low-pressure vacuum chamber, but it faces significant limitations.

Inefficient Plasma Generation

In a simple DC sputtering system, a high negative voltage is applied to the target material. This attracts positive gas ions, but the process is inefficient.

Free electrons, which are crucial for ionizing the gas to create the plasma, are quickly drawn to the positive anode (often the substrate holder) and lost. This requires higher gas pressures to maintain a stable plasma, which can degrade the quality of the final film.

Substrate Damage

The electrons that are not lost immediately can accelerate across the chamber and bombard the substrate. This bombardment imparts significant energy, leading to unwanted heating and potential damage, which is unacceptable for sensitive materials like polymers or electronics.

How the Magnetic Field Solves the Problem

Adding a magnetron—an arrangement of powerful permanent magnets behind the target—fundamentally changes the physics of the process and overcomes these limitations.

Trapping the Electrons

The magnets create a field with lines that emerge from the target and curve back into it. Electrons, being extremely light charged particles, are forced by this magnetic field to travel in a tight spiral or cycloidal path along these field lines.

Instead of traveling directly to the anode, they are trapped in a "race track" pattern close to the target's surface. This dramatically increases their path length within the plasma region.

Creating a Dense, Localized Plasma

Because the electrons are trapped near the target, their probability of colliding with and ionizing neutral argon gas atoms increases by orders of magnitude.

This creates a self-sustaining, high-density plasma that is highly concentrated directly in front of the target where it is needed most. This enhanced ionization efficiency allows the entire process to run at much lower gas pressures.

The Ion Bombardment Cascade

This dense cloud of newly created positive argon ions is now strongly attracted to the negatively charged target. The ions accelerate and collide with the target surface with great force.

If the energy transferred is greater than the material's binding energy, atoms from the target are physically knocked out, or "sputtered." These sputtered atoms then travel through the vacuum and deposit onto the substrate, forming a thin, uniform film.

Understanding the Trade-offs

While highly effective, the magnetic field introduces specific characteristics and potential challenges that must be managed for optimal results.

The "Race Track" Effect

The same magnetic field that makes the process so efficient also confines the plasma to a specific region on the target face.

This localization causes the target material to erode unevenly, forming a distinct groove or "race track." This means that only a fraction of the target material is consumed, which can impact the overall cost-effectiveness and lifetime of the target.

Balanced vs. Unbalanced Fields

The configuration of the magnetic field is critical. A balanced magnetron perfectly confines the plasma close to the target, maximizing the sputtering rate and protecting the substrate.

An unbalanced magnetron is designed to allow some of the plasma to "leak" and extend toward the substrate. This can be used intentionally to cause low-energy ion bombardment of the growing film, which can improve its density, adhesion, and other physical properties.

Key Advantages for Industrial Applications

The use of a magnetic field is what makes sputtering a cornerstone of modern manufacturing for everything from semiconductors to architectural glass.

- If your primary focus is speed and efficiency: The magnetic field's ability to create a dense plasma at low pressures makes magnetron sputtering ideal for high-volume, high-throughput industrial production.

- If your primary focus is film quality: The process generates dense, well-adhered films with uniform thickness, as the sputtered atoms arrive at the substrate with sufficient and consistent energy.

- If your primary focus is coating sensitive materials: By trapping electrons at the target, the magnetic field protects the substrate from excessive bombardment and heating, enabling the coating of plastics, organics, and other delicate components.

Ultimately, the strategic use of a magnetic field transforms sputtering from a slow laboratory technique into a powerful and versatile industrial coating process.

Summary Table:

| Aspect | Without Magnetic Field | With Magnetic Field (Magnetron) |

|---|---|---|

| Plasma Density | Low, inefficient | High, dense, and localized |

| Process Pressure | Requires higher pressure | Operates at lower pressures |

| Deposition Rate | Slow | Significantly faster |

| Substrate Heating/Damage | High risk from electron bombardment | Protected, ideal for sensitive materials |

| Film Quality | Can be inconsistent | Dense, uniform, and well-adhered |

Ready to enhance your coating process with the efficiency of magnetron sputtering? KINTEK specializes in high-performance lab equipment, including sputtering systems designed for superior thin-film deposition. Whether you are developing semiconductors, optical coatings, or need to coat delicate materials, our expertise ensures you achieve precise, high-quality results. Contact our experts today to discuss how our solutions can meet your specific laboratory needs and accelerate your research and production.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications