The primary advantage of a vacuum oven is its ability to dry materials at significantly lower temperatures than a conventional oven. By reducing the ambient pressure, it lowers the boiling point of water and other solvents, allowing for gentle yet highly effective moisture removal without damaging heat-sensitive substances.

The core challenge with many materials isn't just removing moisture, but doing so without degrading or altering the product itself. A vacuum oven solves this by changing the rules of evaporation, making it possible to achieve thorough, uniform drying at temperatures that preserve the material's integrity.

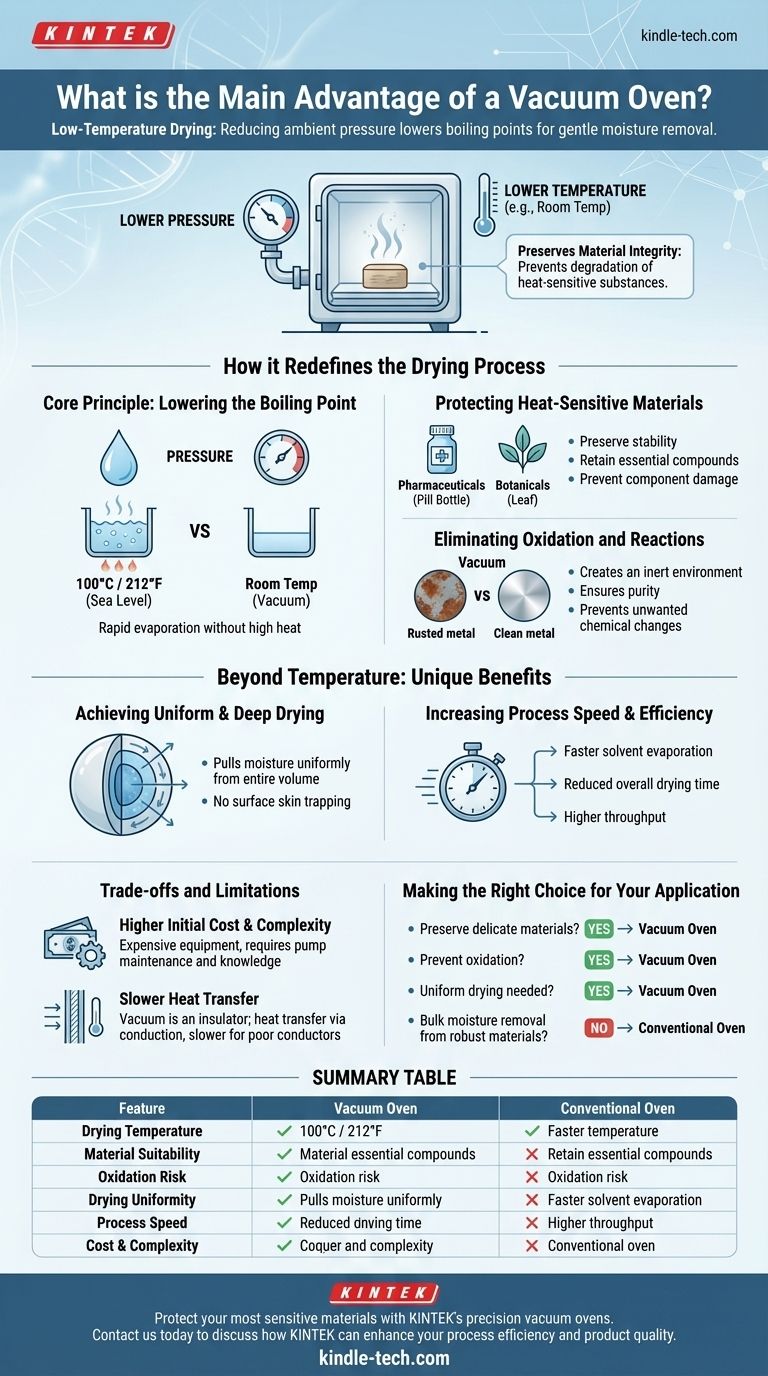

How a Vacuum Oven Redefines the Drying Process

A conventional oven relies solely on high heat to evaporate moisture. A vacuum oven introduces a second, more powerful variable: pressure. This fundamental difference unlocks several key benefits.

The Core Principle: Lowering the Boiling Point

At sea level, water boils at 100°C (212°F). In a vacuum, that boiling point plummets. This means you can achieve rapid evaporation—the "boiling off" of solvents—at room temperature or with only minimal heat.

This allows you to gently dry materials that would be destroyed by the high temperatures of a standard oven.

Protecting Heat-Sensitive Materials

Many advanced materials cannot tolerate high heat. A vacuum oven is essential for applications involving:

- Pharmaceuticals: Preserving the chemical stability of active ingredients.

- Botanicals: Drying delicate plant matter without destroying essential oils and compounds.

- Electronics: Curing components without damaging sensitive microchips or plastics.

Eliminating Oxidation and Reactions

Heat accelerates chemical reactions, especially oxidation (rusting or degradation from contact with oxygen). By removing the air, a vacuum oven creates an inert environment.

This prevents unwanted reactions, ensuring the purity and stability of the material being processed. This is critical for curing certain polymers, chemicals, and metals.

Beyond Temperature: The Benefits of a Vacuum Environment

While gentle heating is the main advantage, the vacuum itself provides unique benefits for achieving a higher quality end product.

Achieving Uniform and Deep Drying

In a conventional oven, the surface of an object dries first, which can form a "skin" that traps moisture inside. This is a common problem with powders or objects with complex shapes.

A vacuum pulls moisture out uniformly from the entire volume of the material. This pressure differential ensures that even the deepest parts are dried completely and consistently.

Increasing Process Speed and Efficiency

Because solvents evaporate much more readily at lower boiling points, the overall drying time at a given temperature can be significantly reduced. This leads to higher throughput and more efficient production cycles.

Understanding the Trade-offs and Limitations

While powerful, a vacuum oven is not the universal solution for all drying tasks. Understanding its limitations is key to using it effectively.

Higher Initial Cost and Complexity

Vacuum ovens, along with the necessary vacuum pumps, are significantly more expensive than their conventional counterparts. They also require more operational knowledge regarding vacuum levels, pump maintenance, and proper sealing techniques.

Slower Heat Transfer

A vacuum is an excellent insulator. This means heat transfer to the product is slower and occurs primarily through conduction from the heated shelves, not through air convection. For materials with poor thermal conductivity, this can sometimes extend the process time compared to a forced-air oven if the material is not heat-sensitive.

Making the Right Choice for Your Application

Selecting the right tool depends entirely on the nature of your material and your processing goals.

- If your primary focus is preserving delicate materials (biologics, pharmaceuticals, botanicals): A vacuum oven is essential for preventing thermal degradation.

- If your primary focus is preventing oxidation or other air-related reactions: The inert environment created by the vacuum is the key advantage.

- If your primary focus is achieving perfectly uniform drying in powders or complex parts: A vacuum oven's ability to pull moisture from deep within is superior to conventional methods.

- If your primary focus is simple, bulk moisture removal from robust, non-sensitive materials: A standard convection or forced-air oven is often the more cost-effective and straightforward choice.

Ultimately, a vacuum oven empowers you to process materials that are simply incompatible with traditional high-heat drying methods.

Summary Table:

| Feature | Vacuum Oven | Conventional Oven |

|---|---|---|

| Drying Temperature | Lower temperatures (can be room temp) | High temperatures required |

| Material Suitability | Ideal for heat-sensitive materials (pharmaceuticals, electronics, botanicals) | Suitable for robust, non-sensitive materials |

| Oxidation Risk | Eliminated (inert environment) | Present (exposure to air) |

| Drying Uniformity | High (moisture pulled from entire volume) | Lower (surface dries first, risking moisture trapping) |

| Process Speed | Faster evaporation at lower temps | Slower evaporation at higher temps |

| Cost & Complexity | Higher initial cost and operational complexity | Lower cost and simpler operation |

Protect your most sensitive materials with KINTEK's precision vacuum ovens.

Are you working with delicate pharmaceuticals, advanced electronics, or botanicals that require gentle, uniform drying without thermal degradation? KINTEK specializes in laboratory equipment designed to meet these exacting needs. Our vacuum ovens provide the low-temperature, inert environment essential for preserving material integrity and preventing oxidation.

Contact us today to discuss how a KINTEK vacuum oven can enhance your process efficiency and product quality. Let our experts help you find the perfect solution for your laboratory's unique challenges.

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- What is the pressure range for pyrolysis? Optimize Product Yields with Precise Control

- What is the purpose of a laboratory vacuum drying oven in catalyst post-processing? Preserve Activity & Pore Structure

- What is partial pressure in a vacuum furnace? Mastering Controlled Atmospheres for Superior Thermal Processing

- How does a specialized small electric heating furnace ensure the accuracy of high-temperature SHPB dynamic tests?

- Can an electric furnace melt steel? Only with the right heating technology.

- What is the difference between combustion pyrolysis and gasification? A Guide to Thermal Conversion Technologies

- How thick is vacuum deposition? Achieve Atomic-Level Precision for Your Coatings

- What are the advantages of using a laboratory vacuum drying oven? Preserve Catalyst Integrity and Nanostructure