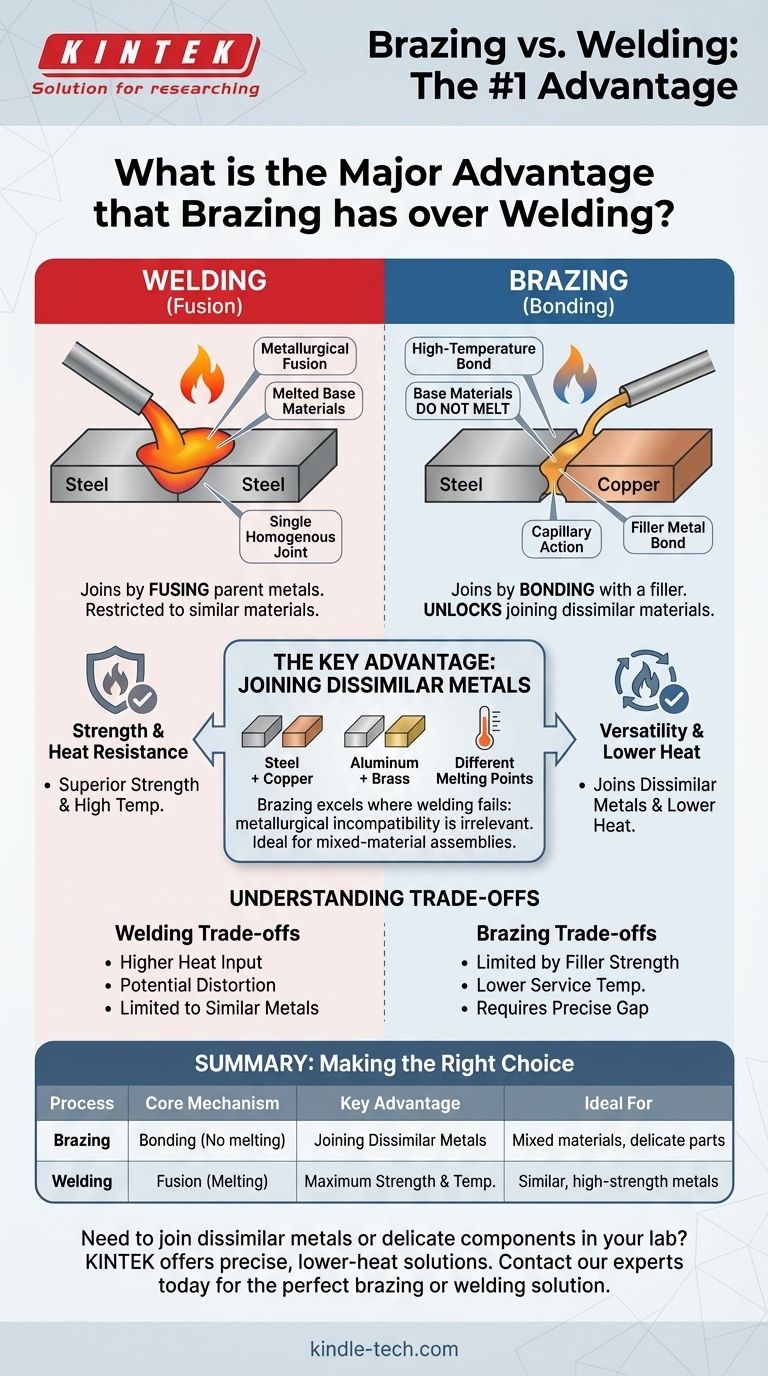

The single greatest advantage of brazing over welding is its ability to join dissimilar metals. While welding fuses the base materials themselves, brazing uses a separate filler metal to bond them without melting. This fundamental difference allows for the successful and strong joining of a wide variety of materials that would be metallurgically incompatible if welded.

The core distinction is simple: Welding creates a joint by fusing the parent metals, which restricts it to similar materials. Brazing creates a joint by bonding the parent metals with a filler, which unlocks the ability to join vastly different materials like steel to copper or aluminum to brass.

The Fundamental Difference: Fusion vs. Bonding

To understand why brazing has this unique advantage, we must first distinguish between the core mechanics of each process. They are fundamentally different approaches to joining metal.

How Welding Works: Metallurgical Fusion

Welding uses high energy to melt the edges of the two base components, often along with a filler material.

These molten materials mix together, forming a single, homogenous pool. Upon cooling, this pool solidifies into one continuous piece of metal, creating a metallurgical bond.

This process results in exceptional strength and heat resistance, as the joint is essentially the same material as the parts being joined.

How Brazing Works: A High-Temperature Bond

Brazing introduces a filler metal with a melting point that is lower than the base materials. The base materials are heated, but they never melt.

The molten filler metal is drawn into the tight-fitting gap between the components through a process called capillary action.

When it cools and solidifies, the filler forms a strong, permanent bond between the two surfaces. This is functionally similar to soldering, but it occurs at much higher temperatures (above 840°F / 450°C) and uses stronger filler materials.

The Key Advantage: Joining Dissimilar Materials

This distinction between melting and not melting the base metals is the source of brazing's primary advantage.

Why Welding Struggles with Different Metals

Attempting to weld two metals with significantly different properties—like melting points, rates of thermal expansion, or chemical compositions—is often impossible.

Melting and mixing them can create brittle, weak alloys in the joint, leading to cracks and immediate failure.

Why Brazing Excels in This Area

Because the base metals in a brazed joint are never melted, their metallurgical incompatibility is irrelevant.

The success of the joint depends only on the ability of the filler metal to adhere to the surface of each base material. This makes it an ideal process for joining a vast range of dissimilar metals.

Understanding the Trade-offs

Choosing brazing for its material versatility means accepting a different set of performance characteristics compared to welding.

When Welding is Superior: Strength and Heat Resistance

The primary advantage of welding is its unmatched strength. Because the final joint is a fused part of the base metals, its strength can equal or even exceed that of the original materials.

Furthermore, a welded joint can withstand any temperature the base metal can, making it the only choice for high-temperature applications.

The Limitations of Brazing

A brazed joint's strength is limited by the strength of the filler metal, which is almost always less strong than the base materials.

Likewise, the joint's maximum service temperature is dictated by the much lower melting point of that same filler metal.

A Secondary Advantage: Lower Heat and Reduced Distortion

Brazing requires significantly less heat input than welding. This lower temperature reduces the risk of thermal stress, warping, and distortion, especially when working with thin or delicate components.

Making the Right Choice for Your Application

The decision between brazing and welding should be driven by the specific demands of your project.

- If your primary focus is joining dissimilar metals: Brazing is the definitive and often only viable solution.

- If your primary focus is maximum strength and high-temperature performance: Welding is the superior choice, assuming you are joining compatible metals.

- If your primary focus is minimizing heat input and distortion on thin materials: The lower temperatures of brazing offer a significant advantage over welding.

Understanding this core difference between fusion and bonding is the key to selecting the right process for a successful and durable joint.

Summary Table:

| Process | Core Mechanism | Key Advantage | Ideal For |

|---|---|---|---|

| Brazing | Bonds metals with a filler, without melting base materials. | Joining dissimilar metals (e.g., steel to copper). | Assemblies with mixed materials, delicate parts. |

| Welding | Fuses base materials by melting them together. | Maximum joint strength and high-temperature resistance. | Joining similar, high-strength metals. |

Need to join dissimilar metals or delicate components in your lab?

Brazing offers a precise, lower-heat solution that welding cannot match. At KINTEK, we specialize in providing the right lab equipment and consumables for your specific joining challenges. Our expertise ensures you get durable, reliable results for your research and production needs.

Contact our experts today to find the perfect brazing or welding solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What are the 3 stages of annealing? Master the Process to Optimize Metal Properties

- Is aluminum brazing as strong as welding? A Guide to Choosing the Right Joining Method

- What are the advantages of electric arc furnace over blast furnace? Boost Efficiency & Sustainability

- What role does a laboratory vacuum oven play in WBPUU film post-treatment? Optimize Film Density and Structural Integrity

- How does a pyrolysis reactor influence carbon materials for supercapacitors? Mastering Biomass Energy Storage

- What is the primary function of a vacuum oven in FEP membrane prep? Ensure Defect-Free Fiber Production

- What are the functions of sintering? Achieve Superior Material Properties from Powder

- What is the suitable temperature to process the material in the sintering stage? Find the Perfect Sintering Sweet Spot